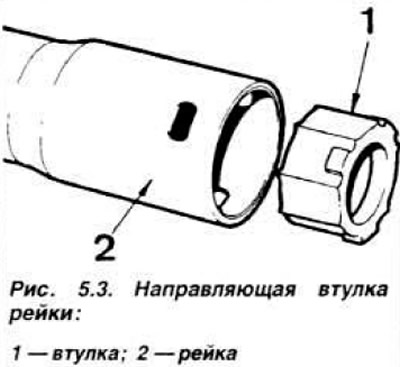

Install, if necessary, a new thrust sleeve in the steering gear housing and insert the rack into the steering gear housing. Install the bearing and drive gear into the crankcase, having previously set the gear to the middle position.

NOTE: After installing the flat of the drive gear, it should be perpendicular to the axis of the rack (pic. 5.4) and directed to the right.

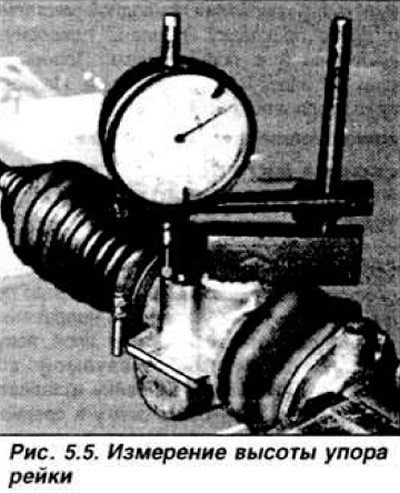

Install the gasket and cover, then the oil seal. that the cover is located in the center of the drive gear. apply sealant to the cover mounting bolts and tighten them to a torque of 1.7–2.4 kgf·m Set the dial indicator to the stop and bring its leg to the crankcase surface to which the stop cover adjoins (fig 5.5).

Moving the rail from one extreme position to another, note the maximum difference in the readings of the device. Select shims so that their total thickness is 0.05–0.125 mm greater than the resulting difference in reading. Example: measurement difference 0.80 mm. The recommended gap is 0.015-0.150 mm. Required thickness of washers with spacer 0.815-0.950 mm Install stop, spring, matched washers, spacer and cover and adjust gap between stop and rail as described in the next paragraph. Install the axial hinge bearings, tie rods, hinge housings and locknuts on the rail. Lubricate joints, tie rod bearings and axle joint housings before installation. Adjust the tightening of the hinges as follows: tighten the locknuts of the hinge housings, at a distance of 6 mm from the end of the threaded part of the steering rod, hook the hook, the other side of which is fixed on the steelyard (pic. 5.6) and measure the hinge rotation force from the position «in a straight line» (from the axis of the steering gear housing).

Unscrew the locknut and adjust the position of the hinge housing as follows. so that the force is equal to 2.3 kgf. Tighten locknut. Pin and drill a hole with half the diameter in the hinge body, half in the body of the locknut with a diameter of 4.0 mm and a depth of not more than 9.5 mm (rice. 5.2). Drill new holes even if old holes are aligned. Install new pins and punch them around the circumference Lubricate the contact surface of the protective boot on the steering gear housing and install the boot. Apply 95 cm3 of Ford SAM-1 specification C-9106 A semi-fluid grease and move the rack to evenly distribute the grease Install the second protective boot. Measure the turning resistance torque of the drive gear as described below.

Visitor comments