This test requires the accelerator pedal to be fully depressed and the proper wire connected to the downshift switch. Unscrew the vacuum pipe from the intake manifold to the computer and plug it. Start the engine and set the engine speed to 1000 rpm. The strobe should show 12°.

NOTE: Since the ignition coil has two leads, the instrument will display pulses for two cylinders. therefore, to obtain the value of UOZ, it is necessary to divide the instrument reading by two.

Carry out a check for crankshaft speeds of 2100-3050 and 3100-6500 rpm. If the strobe reads 16°, check for an open in the wire connecting the positive downshift switch to «weight», as well as the condition of the insulating lining of the switch.

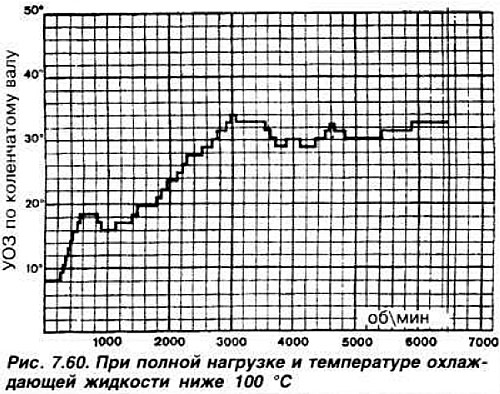

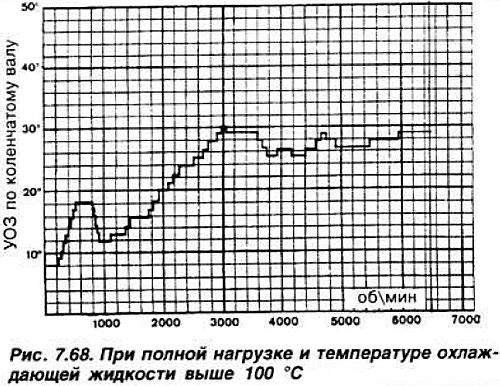

Full load test

Run all test prerequisites above and disconnect the wire from the positive downshift switch. The strobe should show 16°and the RPM should rise slightly. Otherwise, check the coolant temperature sensor and the wire connecting this sensor to the ignition ECU.

Partial load test

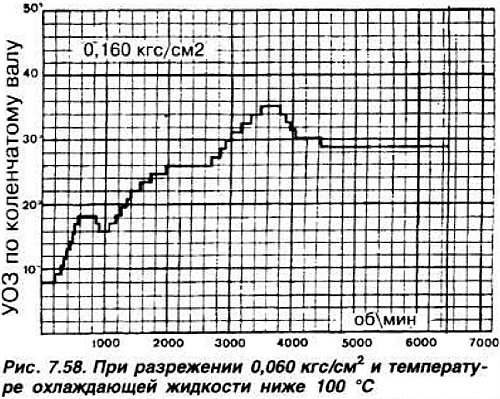

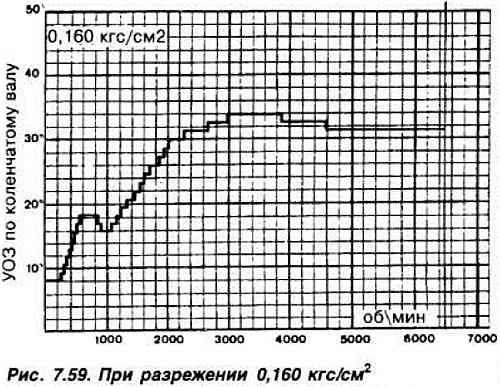

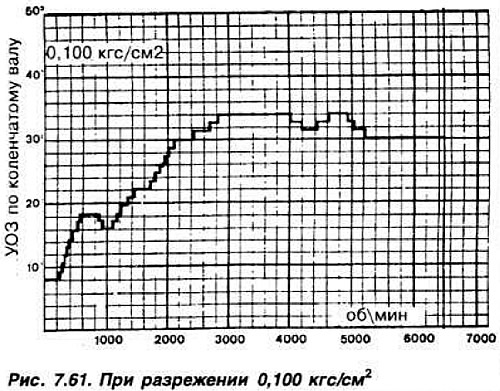

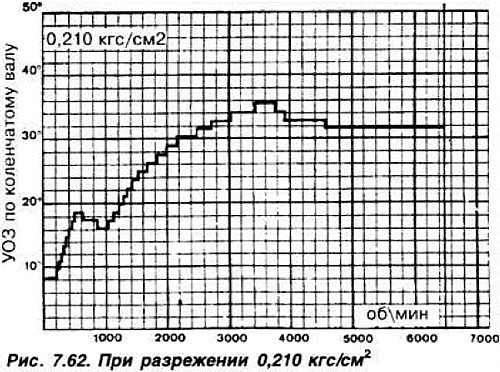

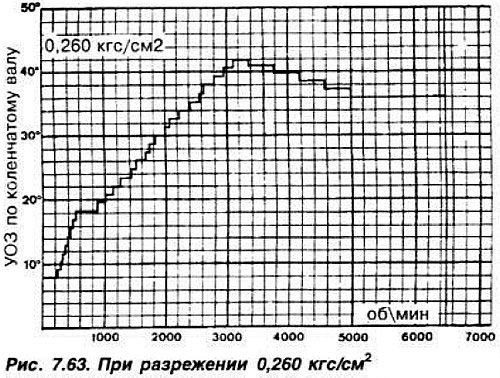

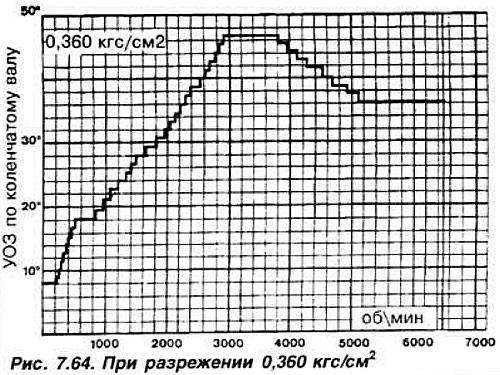

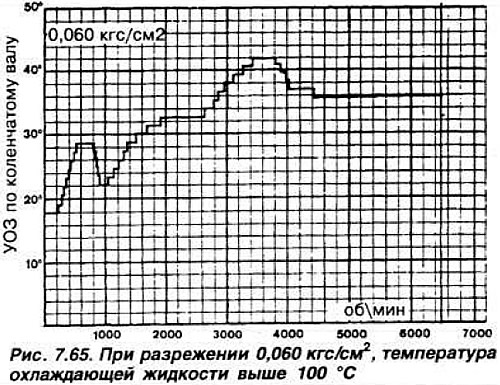

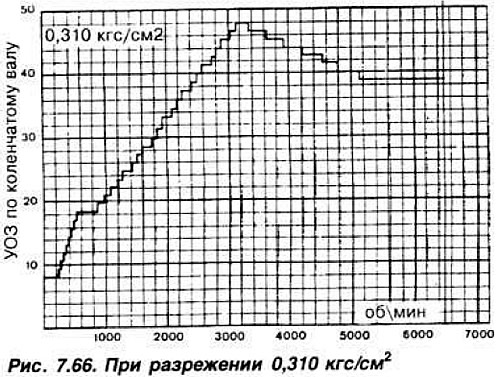

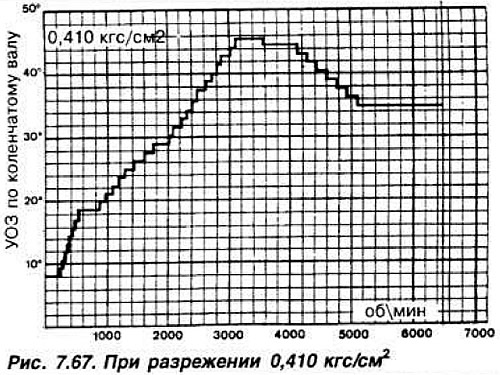

Connect the vacuum pump to the ECU vacuum tube and create a vacuum of 0.065 kgf/cm2. Increase the speed and observe the strobe readings. Note its readings at 1000, 2000, 3600, 4100 and 4600 rpm and divide them in half. Run a test for a vacuum of 0.060; 0.110; 0.160; 0.210; 0.260; 0.310; 0.360 and 0.410 kgf/cm2. If the coolant temperature is above 100°C after the full load test, the values of the first partial load test curve (0.060 kgf/cm2) will be lower by 4°The rest of the graphs will be normal To check, disconnect the wire from the temperature sensor and short it to «mass».

Checking the ignition safety switch

Engage 1st gear and move in it. depressing the accelerator pedal until the ignition safety switch operates at 6500 rpm. If operation does not occur, check flywheel, switch sensor and electrical connections.

Visitor comments