NOTE: Do not test spark plugs by shorting ground electrode to «mass», as this will immediately disable the switch.

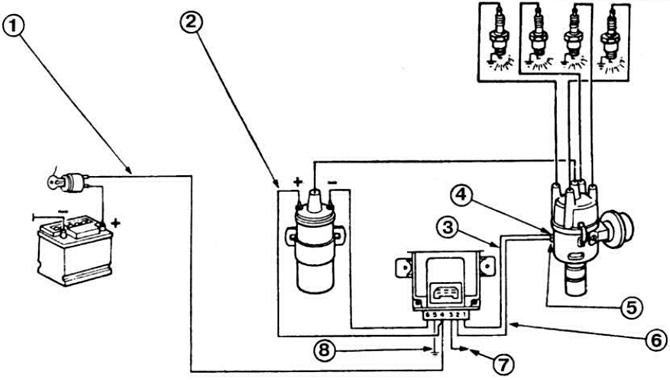

Pic. 7.49. Diagram of a contactless ignition system.

Pic. 7.49. Diagram of a contactless ignition system.

1 - red wire; 2 - pink wire; 3 - green wire; 4 - output «4»; 5 - output «IN»; 6 - brown wire; 7 - output of the tachometer; 8 - green wire.

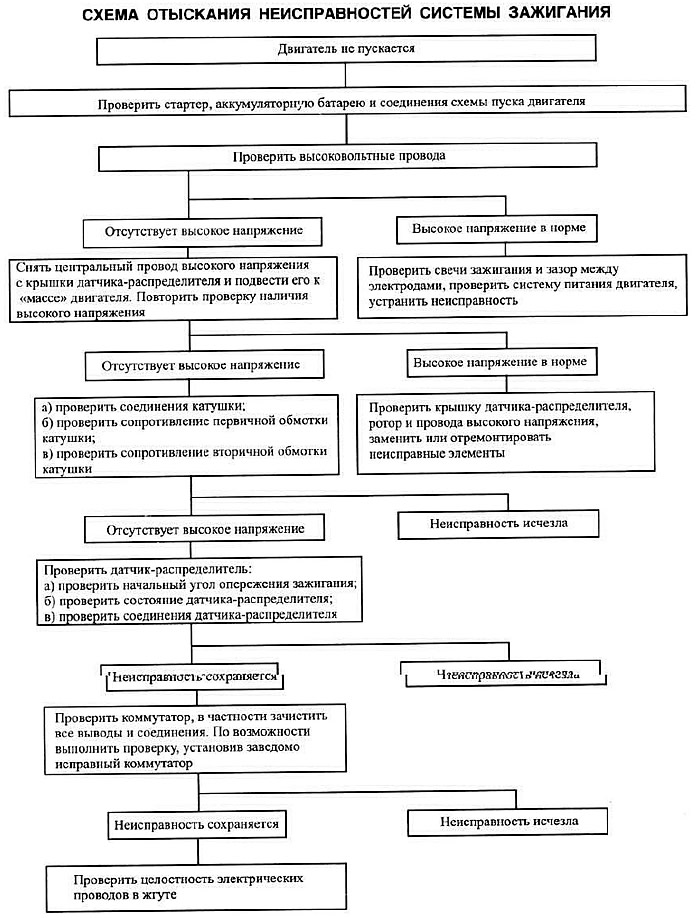

In the event of a malfunction or interruption in the operation of the ignition system, check the system according to the troubleshooting scheme.

Checking high voltage wires

Pulling on the tip, remove the wire from the candle and put the tip on a spare candle or a metal bar. Engage starter and check for spark between «weight» and an electrode located at a distance of not more than 5 mm.

NOTE: It is recommended to hold the wire with pliers with insulated handles. Do not hold the electrode more than 5 mm from «masses», to avoid damage to the switch.

If there is no spark, remove the central wire from the cover of the distribution sensor and check it in the same way.

Checking the resistance of high voltage wires

Disconnect the wires from the battery, remove the wires from the spark plugs and ignition coils. Using an ohmmeter, measure the resistance of each wire, which should not exceed 7500 ohms. otherwise, replace the wire.

Checking the resistance of the ignition coil windings

By connecting an ohmmeter to the low voltage terminals, measure the resistance of the primary winding (0.72-0.88 ohm), and between the high voltage terminals - the resistance of the secondary winding of the ignition coil (4.5-7.0 kOhm).

Removing and installing the sensor-distributor and setting the ignition timing

Removal and installation of the sensor-distributor and installation of the ignition moment are carried out in the order recommended for the ignition system with the distributor. The only difference is the pulse sensor connector (disconnect when removing and connect when installing the distributor sensor).

Checking the Delay/Vacuum Boost Valve

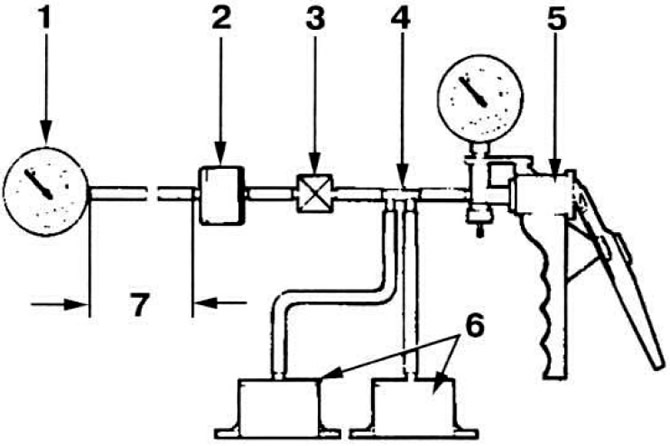

Assemble the test circuit shown in Fig. 7.50.

Pic. 7.50. Scheme for checking the valve delay / amplification of vacuum.

Pic. 7.50. Scheme for checking the valve delay / amplification of vacuum.

1 - a device for measuring vacuum; 2 - checked valve; 3 - crane; 4 - connecting pipe; 5 - manual vacuum pump; 6 - receivers for vacuum; 7 - tube 60 cm long.

Delay valve side labeled «CARB» connect to the vacuum pump, and the side of the vacuum amplification valve with the inscription «DIST» - to the vacuum gauge. Create a vacuum of 250 mm R.St. with the control valve closed Open the valve and note the time to reach a vacuum of 200 mm Hg, which should be 1-9 seconds for the delay valve. for vacuum amplification valve 8-16 sec.

Visitor comments