For engines of all models except GLA

Turn the crankshaft until the EZMT marks are aligned and remove the toothed belt cover. Loosen the toothed belt tension and remove it. Drain coolant. Disconnect the hoses going to the radiator and to the heater. Remove the toothed belt tensioner Loosen the four mounting bolts (rice 2.65) and remove the water pump.

Before installing the water pump, it is necessary to remove the remnants of the old gasket from the mating surfaces, install a new gasket 3 (pic. 2.66) and install a water pump.

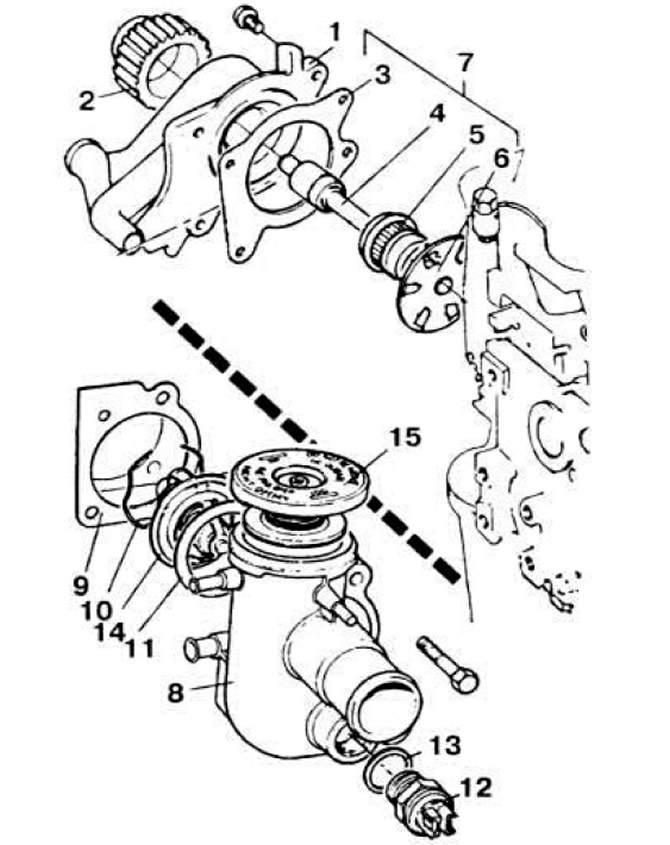

Pic. 2.66. Details of the water pump and thermostat housing.

Pic. 2.66. Details of the water pump and thermostat housing.

1 - water pump; 2 — a gear pulley of a drive of the water pump; 3, 9 - gaskets; 4 - pump roller with bearing; 5 - cuff of the water pump; 6 - impeller; 7 - water pump repair kit; 8 - thermostat housing; 10 - retaining ring; 11 - rubber ring; 12 - sensor for turning on the electric fan; 13 - fiber pad; 14 - thermostat; 15 - thermostat housing plug.

Install the tensioner and put on the toothed belt as described in section «Camshaft and its drive». Install the toothed belt cover, put on the alternator drive belt and tighten it. Connect the hoses to the radiator and heater, fill the system with coolant. start the engine and make sure there are no leaks.

For GLA model engine

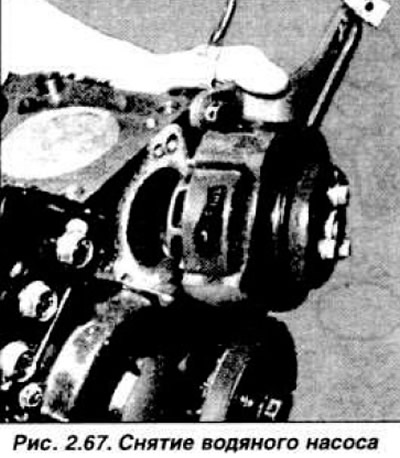

Release access to the mounting bolts and remove the water pump pulley Remove the water pump (pic. 2.67). using, if necessary, a mallet with a plastic striker.

Remove the remnants of the old gasket, check the condition of the parts. Before installing a new gasket, apply a coat of Perfect Seal and install the water pump in the reverse order of its removal. Tension the drive belt as above.

Checking the technical condition of the water pump of the GLA engine

Install the pump on a special stand and compress the drive flange. Turn the pump over and knock out the impeller with the shaft and stuffing box assembly. Press the impeller off the shaft and remove the stuffing box. Clean and inspect parts, replace parts, the technical condition of which is unsatisfactory. Assemble the pump in the reverse order of disassembly, taking into account the following: the shaft must protrude 1.5 mm beyond the drive flange. When pressing the shaft with stuffing box and impeller assembly into the pump housing, ensure a gap of 0.80 mm between the impeller and the housing (pic. 2.68).

Visitor comments