- if a defect is found on one of the elements of the input shaft, replace the input shaft;

- in case of re-installation of bearings, do not dismantle them (outer and inner rings);

- in case of disassembling the synchronizer, make sure, before removing the sliding sleeve from the hub, that that they are marked with relative positions (pic. 3.31). otherwise, apply the necessary marks;

- store the locking rings of synchronizers together with the corresponding gears;

- do not use sharp tools or metal blades to clean the parting surfaces of aluminum alloy crankcases. Use cloths moistened with solvent or trichlorethylene.

Output shaft assembly

Assembly is carried out in the reverse order of disassembly. On the previously lubricated secondary shaft, install the gear of the 1st gear in series, while its conical surface should be turned in the direction opposite to the drive gear of the main gear; blocking ring, hub and sliding clutch of the synchronizer of I and II gears, the groove of the clutch for the fork should be located near the gear of the 1st gear; the blocking ring is a new retaining ring, the gear of the 2nd gear, both thrust half rings, while their protrusions must enter the grooves of the output shaft, and their cage, the gear of the 3rd gear, the blocking ring, the hub and the sliding sleeve of the synchronizer of the 3rd and 4th gears and a new locking ring; blocking ring, fourth gear gear. Press the bearing in until it stops and install the circlip.

Input shaft assembly

To install the bearings, use pieces of pipe of the appropriate diameter, press it in until it stops. Install a bearing with a groove on the side of the 4th gear gear (larger diameter bearing).

Differential Assembly

Install the speedometer drive gear. Paying attention to the position of its spike, using mandrel 15.025 or a piece of pipe of the appropriate diameter, install the bearings in the differential box. Get an axle. install satellites and retaining rings. Insert the side gears through the cutouts in the box, put them in place, paying attention to the correct fit, and install a plastic or wooden mandrel (pic. 3.32).

Install the driven gear of the final drive with the beveled part to the differential box and fix it with new bolts, gradually tightening them up to a torque of 9.8-12.8 kgf·m.

Installation of shafts and gear selection mechanism

In the bore of the clutch housing under the roller bearing of the input shaft, install the oil deflector 26 (rice. 3.7). Install plastic separator (pic. 3.33) until it comes into contact with the oil deflector, paying attention to the correct centering of it. Install the rollers in the separator.

Slightly punch out the outer ring of the bearing around the circumference. so that it does not rotate in the crankcase. Install the differential case with the speedometer drive gear down. Install the reverse idler gear by inserting the engagement lever pin into the annular groove of the gear. At the same time, install the primary and secondary shafts into the crankcase, lifting up the intermediate reverse gear so that it is above the 1st gear gear. Install spring 6 (pic. 3.34) fork axles into the socket.

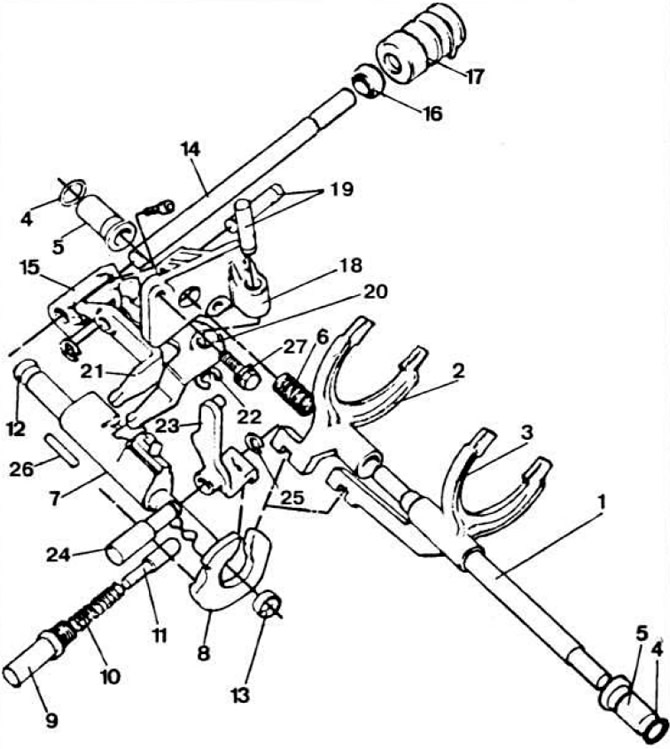

Pic. 3.34. gear selection mechanism.

Pic. 3.34. gear selection mechanism.

1 - axis of shift forks; 2 — a fork of switching of I and II transfers; 3 — a fork of switching of III and IV transfers; 4 - ring; 5 - sleeve; 6 - spring; 7 — a stock of a choice of transfers; 8 - locking bracket; 9 - stopper of the latch; 10 - retainer spring; 11 - latch pin; 12 and 13 - bushings of the gear selection rod; 14 — an intermediate shaft of a choice of transfers; 15 - leash; 16 - stuffing box; 17 - protective cover; 18 - support levers for selecting forward gears; 19 - axes; 20 and 21 - levers for selecting forward gears; 22 and 25 - retaining rings; 23 - reverse gear lever; 24 — an axis of the lever of inclusion of a backing; 26 - pin.

Install locking bracket (pic. 3.35) and shift forks.

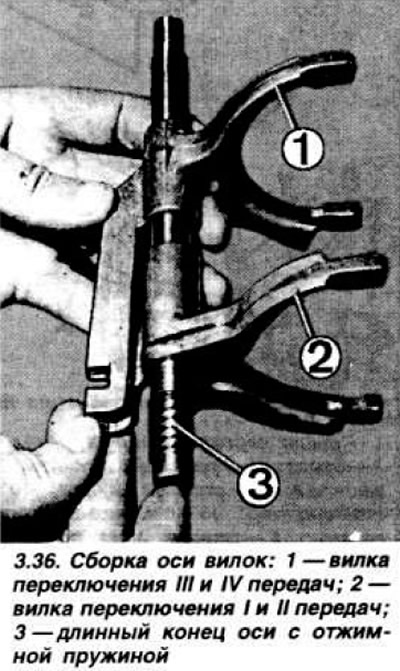

Set on the same line the half rings of the forks (pic. 3.36) and start the fork axle 1 (pic. 3.34) long end into the spring previously installed in the crankcase.

Check the inclusion of all gears, leave the IV gear on for subsequent adjustment of the gear shift drive after installing the gearbox on the car. Reinstall the magnetic washer and secure it with grease to do so. so that it does not move during the installation of the back cover. Install the outer ring of the bearing in the rear part of the differential box, having previously placed two elastic washers - with the flat side of the smaller washer in the box seat, with the flat side of the larger washer towards the bearing ring. Drill out the bearing race at two points. Apply a thin layer of oil to the plane of the crankcase connector, install the gasket and clutch housing using a plastic mallet. Gradually tighten the fastening bolts to a torque of 2.5 kgf·m. From the three possible thicknesses, choose the adjusting rings as follows. so that they enter without a gap into the grooves at the outer ends of the shafts, install them. lifting the shafts with a screwdriver up. Position adjusting rings according to gasket cutouts (pic. 3.37) so that there is no overlap.

Install a new gasket and rear cover. Install the pin, spring, and selector rod retainer plug. Install the clutch release bearing, fork and lever.

Visitor comments