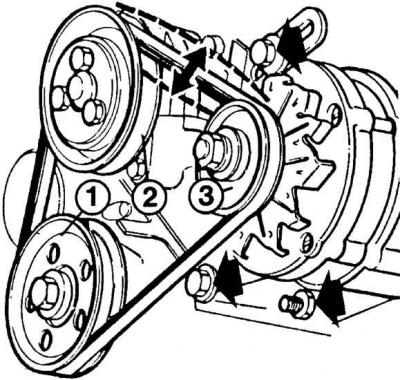

OHV engine alternator belt tension

1 - crankshaft pulley; 2 – a pulley of the water pump; 3 - generator pulley

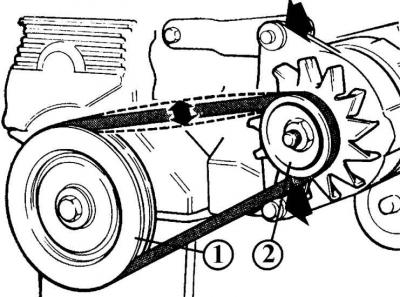

CVH engine alternator belt tension

1 - crankshaft pulley; 2 - generator pulley

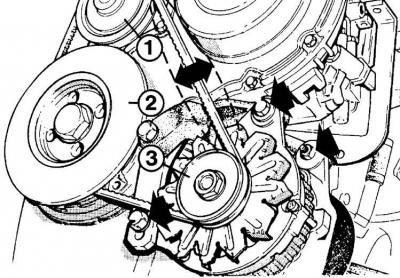

Diesel generator belt tension

1 - crankshaft pulley; 2 – a pulley of the water pump; 3 - generator pulley

V-belt tension is measured with a special measuring device on a cold engine.

A belt is considered used if it has been in operation for at least 10 minutes.

Examination

In the absence of a measuring device, the belt tension can be checked by pressing the thumb on the longest section of the belt. The correct tension corresponds to a belt deflection of about 10 mm. A V-belt with frayed edges, tears, cracks and burn marks must be replaced.

Adjustment

1. Loosen the two bolts securing the alternator to the engine.

2. Loosen the tension bolt and move the generator towards the engine if the belt tension is more than required, or away from the engine if the tension is not enough.

3. Tighten the tension bolt and then the bolts securing the alternator to the engine.

| New belt tension: | |

| – OHV engine | 400±150 N |

| – CVH engine | 300±150 N |

| Used belt tension: | |

| – OHV engine | 450±150 N |

| – CVH engine | 350±150 N |

Visitor comments