1. Check ignition timing.

2. Check the condition and electrode gap of the spark plugs.

3. Check that the accelerator cable, and on models with a carburetor, the choke control cable are correctly adjusted.

4. Check that the crankcase ventilation hoses are not clogged or kinked.

5. Make sure the air filter element is clean.

6. Check that the exhaust system is in good condition.

7. If the engine runs very rough and unstable, check the compression in the engine cylinders.

8. Carry out a test drive to warm up the engine to normal operating temperature.

Models with Ford VV carburetor

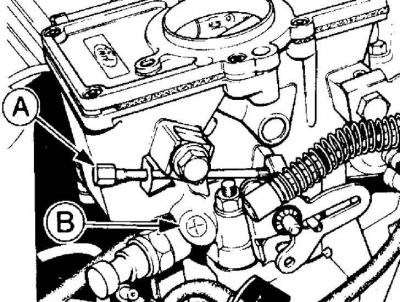

The location of the idle speed and CO content adjustment screws on the Ford VV carburetor

And – the screw of adjustment of turns of idling;

B - CO content adjustment screw

Idle speed adjustment

1. Connect the tachometer to the engine in accordance with the operating instructions.

2. Warm up the engine to normal operating temperature.

3. Disconnect the multi-pin electrical connector of the radiator fan temperature sensor located on the thermostat housing and, using an additional piece of wire, connect the connector contacts, while the radiator fan will run constantly.

4. On models with automatic transmission, loosen the linkage by turning the throttle lever until there is a gap of 2-3 mm.

5. Check that the air filter is in place and that the vacuum hoses are not kinked, especially between the air filter housing and the carburetor.

6. Increase the engine speed to 3000 rpm and hold it for 30 seconds, and then turn the engine to idle. When using a gas analyzer, it will be noted that the percentage of CO in the exhaust gases will initially increase, then begin to decrease and stabilize within 5-25 seconds.

7. If necessary, adjust the idle speed with a screw located on the carburetor (see fig. The location of the idle speed and CO content adjustment screws on the Ford VV carburetor).

Adjusting the quality of the fuel mixture (SO)

Usually adjustment of the quality of the mixture is not required, however, if the CO content in the exhaust gases exceeds the permissible limits, it is necessary to make an adjustment.

1. Using the blade of a thin screwdriver, remove the plastic plug covering the fuel mixture adjustment screw.

2. Increase the engine speed to 3000 rpm and hold it for 30 seconds, and then turn the engine to idle.

3. Within the next 30 seconds, by turning the adjusting screw, adjust the CO content in the exhaust gases (see fig. The location of the idle speed and CO content adjustment screws on the Ford VV carburetor).

4. If more time is needed for adjustment, increase the engine speed again to 3000 rpm and hold it for 30 seconds, then return the engine to idle and make further adjustments.

5. Check the idle speed and, if necessary, adjust them, and then re-check the CO content.

6. Install the plug on the fuel mixture adjustment screw.

7. Remove all used devices, disconnect the additional wire from the connector and connect the connector to the radiator fan temperature sensor.

8. On models with automatic transmission, adjust the downshift linkage.

Weber 2V carburetor

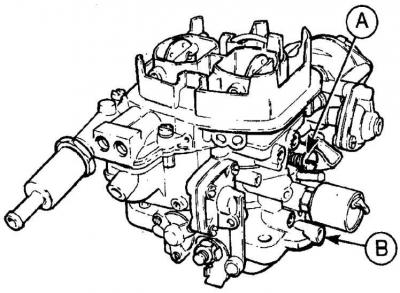

The location of the screws for adjusting idle speed and CO content on the Weber 2V carburetor on XR3 and 1.4 L models

And – the screw of adjustment of turns of idling;

B - CO content adjustment screw

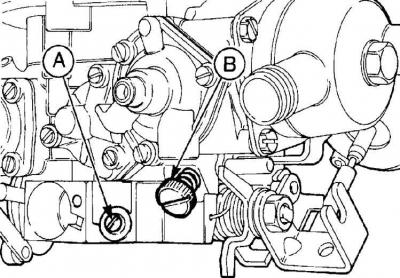

The location of the screws for adjusting idle speed and CO content on the Weber 2V carburetor on 1.6 liter models

And – the screw of adjustment of turns of idling;

B - CO content adjustment screw

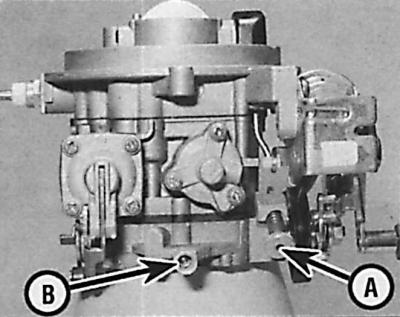

The location of the idle speed and CO content adjustment screws on the Weber 2V TLDM carburetor on the 1.1 and 1.3 L HCS models

And – the screw of adjustment of turns of idling;

B - CO content adjustment screw

Make adjustments in the same way as on the Ford VV carburetor, but keep in mind that the adjusting screws are located differently.

Bosch K-Jetronic fuel injection system

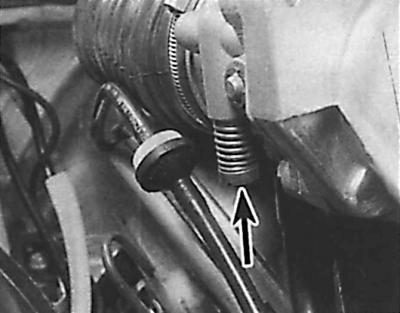

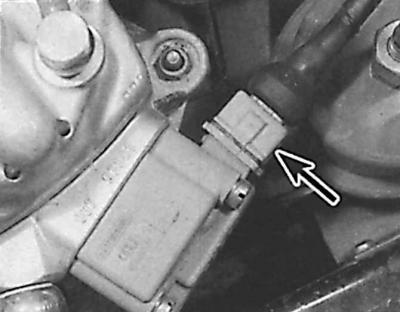

The location of the idle speed screw on the throttle body on early Bosch K-Jetronic fuel injection systems

Early models idle speed screw (indicated by an arrow) is located at the lower rear of the throttle body and access to the screw is restricted.

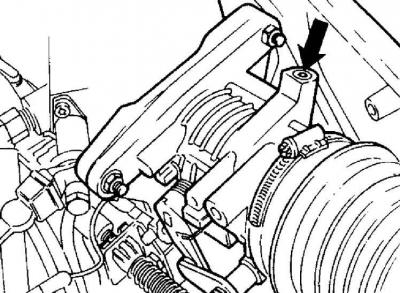

The location of the idle speed screw on the throttle body on late Bosch K-Jetronic fuel injection systems

Late model idle speed screw (indicated by an arrow) located in the upper part of the throttle body under the plug.

Attention! Adjustment of idle speed and mixture quality should be made only after installing new components.

1. Connect the tachometer to the engine in accordance with the operating instructions.

2. Warm up the engine to normal operating temperature.

3. Increase the engine speed to 3000 rpm and hold it for 30 seconds, and then turn the engine to idle. If necessary, adjust the idle speed.

4. To check and adjust the CO content in the exhaust gases, it is necessary to use a gas analyzer and a 3 mm hex key.

5. Check idle speed.

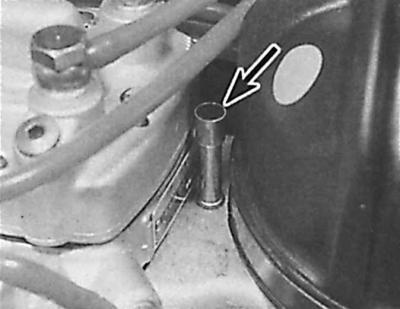

6. Remove plug (arrow) from the top of the fuel mixture adjustment screw tube on the fuel distributor.

7. Check and, if necessary, adjust the CO content in the exhaust gases by turning the adjusting screw with a hex wrench. If necessary, correct the idle speed.

8. If more time is needed for adjustment, increase the engine speed again to 3000 rpm and hold it for 30 seconds, then return the engine to idle and make further adjustments.

9. Install the plug on the adjusting screw, disconnect the gas analyzer and tachometer.

Fuel injection system Bosch KE-Jetronic

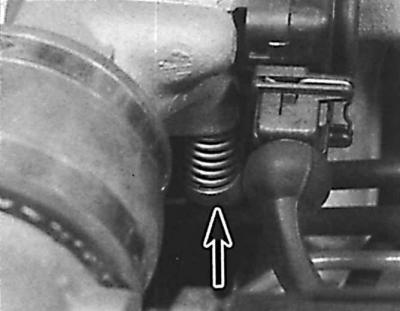

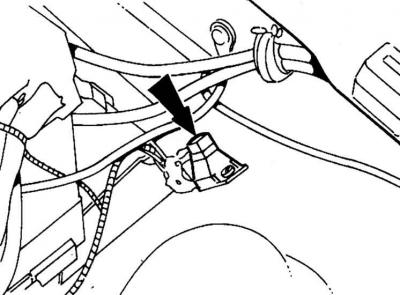

The location of the idle speed adjustment screw on the throttle body on Bosch KE-Jetronic fuel injection systems

Late model idle speed screw (indicated by an arrow) located on the side of the throttle body.

Attention! Adjustment of idle speed and mixture quality should be made only after installing new components.

1. Connect the tachometer to the engine in accordance with the operating instructions.

2. Warm up the engine to normal operating temperature.

3. Disconnect the multi-pin electrical connector (indicated by an arrow) in the pressure actuator, located on the side of the fuel distributor.

4. Increase the engine speed to 3000 rpm and hold it for 30 seconds, and then turn the engine to idle. If necessary, adjust the idle speed.

5. To check and adjust the CO content in the exhaust gases, it is necessary to use a gas analyzer and a 3 mm hex key.

6. Check idle speed.

7. Unscrew the plug (arrow) from the top of the fuel mixture adjustment screw tube on the fuel distributor.

8. Check and, if necessary, adjust the CO content in the exhaust gases by turning the adjusting screw with a hex wrench. If necessary, correct the idle speed; in this case, the hex key must be removed, as the fuel distributor may be damaged.

9. If more time is needed for adjustment, increase the engine speed again to 3000 rpm and hold it for 30 seconds, then return the engine to idle and make further adjustments.

10. Screw the plug onto the adjusting screw, disconnect the gas analyzer and tachometer.

Central fuel injection system

The idle speed and the CO content in the exhaust gases are regulated by the control unit, manual adjustment is not required.

EFI electronic fuel injection system

The idle speed is controlled by the EEC IV control unit, manual adjustment is not provided.

1. To adjust the quality of the fuel mixture, warm up the engine to operating temperature.

2. Connect the gas analyzer and tachometer according to the instructions.

3. Increase the engine speed to 3000 rpm and hold it for 15 seconds, and then turn the engine to idle.

4. After stabilization of the instrument readings, check the idle speed and the CO content in the exhaust gases.

5. To adjust the CO content in the exhaust gases, remove the plug from the adjustment potentiometer located on the wing panel behind the left pillar support (indicated by an arrow) and, by turning the potentiometer screw, set the required CO content at the appropriate idle speed.

6. If more time is needed for adjustment, increase the engine speed again to 3000 rpm and hold it for 30 seconds, then return the engine to idle and make further adjustments.

7. Install a new plug on the adjusting potentiometer, disconnect the gas analyzer and tachometer.

Visitor comments