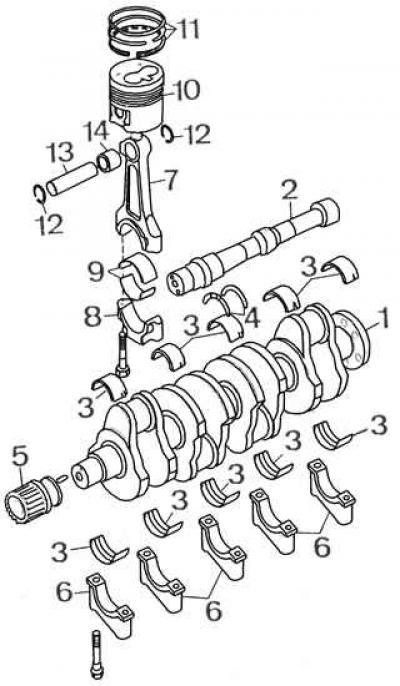

Crank mechanism

1 - crankshaft; 2 - intermediate shaft; 3 – liners of main bearings of a cranked shaft; 4 - thrust half rings of the crankshaft; 5 - pulley; 6 - caps of main bearings; 7 - connecting rod; 8 - connecting rod cover; 9 - liners of connecting rod bearings; 10 - piston; 11 - piston rings; 12 – a lock spring ring; 13 - piston pin; 14 - bushing of the connecting rod head

It is recommended to thoroughly clean and wash the parts to be used again. Removing the plugs and plugs from the cylinder block and cylinder head makes flushing them much easier. All gaskets and O-rings should be replaced every time the engine is disassembled.

Checking the dimensions given in the data sheet and comparing them with the actual values decides whether the part can be reused, repaired or replaced with a new one. The condition of some parts is also evidenced by the condition of their surface (scratches, shells, etc.).

Checking the clearances of the crankshaft and connecting rods

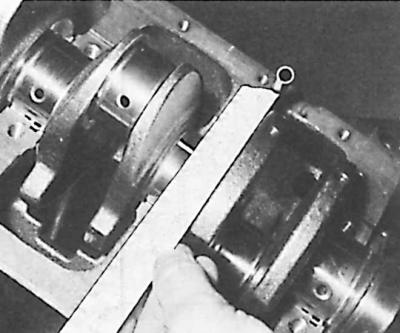

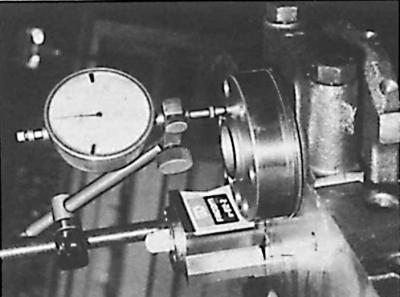

Measuring the deformation of the Plastigage measuring rod to determine the clearance in the main bearing of the crankshaft

Radial Clearance

The radial clearance in the main and connecting rod bearings of the crankshaft is measured using special Plastigage measuring rods made of artificial material. Measuring rod laid along the neck (main or connecting rod) and clamped in the bearing, is subjected to flattening. The radial clearance in a bearing can be determined (based on the corresponding scale on the packaging of measuring rods) depending on the width of the deformed rod.

Measuring conditions with Plastigage measuring rods:

- necks and liners must be dry and thoroughly degreased;

- the crankshaft must not change its position during the installation and removal of the measuring rods;

- the measuring rod must be laid in half of the liner, at a greater distance from the oil hole in the liner or shaft neck;

- bearing caps must be installed by hand, and their bolts must be tightened to the appropriate torque; you can not strike on the covers;

- tighten only the bearing cap in which the radial clearance is measured; it is impossible to simultaneously measure the clearances in all main bearings.

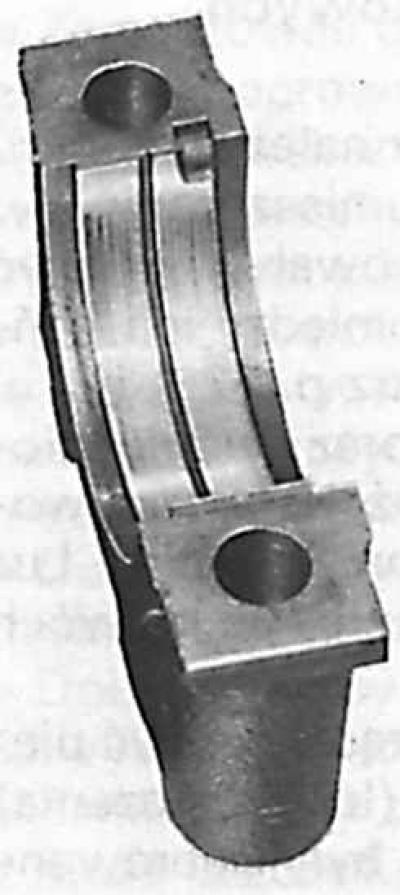

Loose leaf of 1 radical bearing of a cranked shaft

The crankshaft main bearing shell 1 is larger than the rest of the bearing shells and has an oil groove.

1. Install the shells on the main bearings in the engine block and install the crankshaft in them.

Attention! Inserts of the first main bearing (from the drive side of the gas distribution system) are larger than the rest of the bearings and both have an oil groove. In the remaining bearings, the liners on the side of the cylinder block have an oil groove, and on the side of the cover they have a smooth surface.

2. Place the Plastigage dipstick on the first main journal.

3. Install the main bearing cap together with the bushing and tighten the mounting bolts to the correct torque.

4. Carefully remove the bearing cover and measure the width of the deformed stylus using the scale supplied with the measuring rods. Based on the table or graph, determine the radial clearance in the bearing.

5. Compare the measured value with the desired clearance. If the measured gap exceeds the allowable value, repair inserts should be used.

6. In a similar way, measure the clearance in the remaining main and connecting rod bearings.

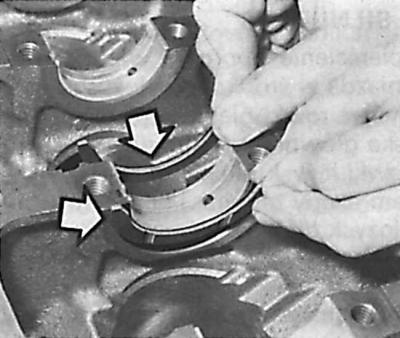

Axial clearance

1. After installing the crankshaft in the cylinder block, install the thrust half rings of the crankshaft (oil grooves must be directed outward of the main bearing), bearing caps and tighten them to the appropriate torque.

2. Rest the measuring tip of the dial indicator against the end of the crankshaft and measure its axial clearance.

3. Compare the measured values with the required values. If the gap exceeds the permissible value, then repair thrust half-rings of a correspondingly larger thickness should be used.

Checking piston rings and piston clearances in the cylinder

1. After removing the rings from the pistons, measure their clearance in the piston grooves, and after installing them in the cylinders in which they stood earlier, measure the width of the lock (clearance) between their ends.

2. Measure cylinder diameters and piston diameters (in the guide, below the piston pin hole) at right angles to the axis of the piston pin. The piston clearance in the cylinder is equal to the difference between these two measurements.

3. Using a special tool, install the rings on the pistons so that the inscriptions (or designations) were directed towards the bottom of the piston. Place the cuts of the rings at an angle of about 120°.

Visitor comments