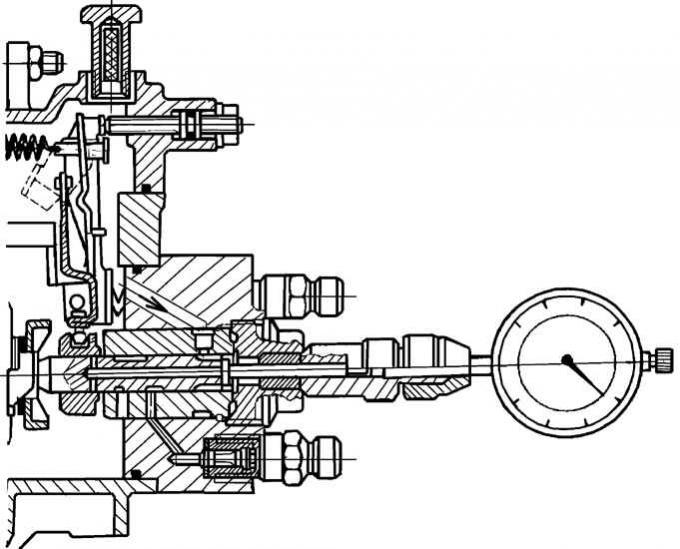

Adapter with indicator for setting injection timing

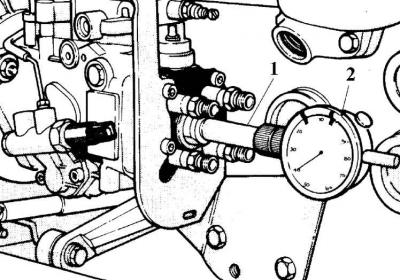

Fastening of an adapter with the indicator for installation of the moment of injection

1 - indicator stand; 2 - indicator

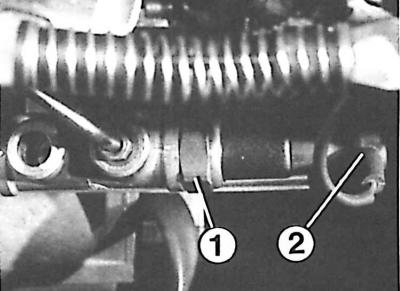

Temperature switch for cold start of the engine and its connector

1 - temperature switch for cold start of the engine; 2 - connector

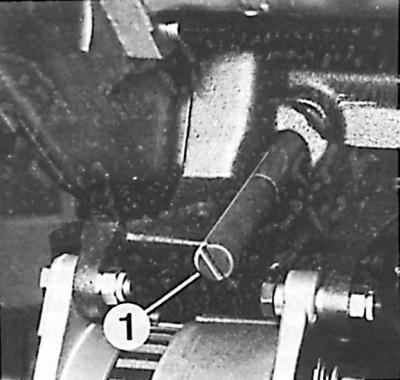

Drift for installing the crankshaft in the TDC position

1 - mandrel (installed in the engine block)

Engine 1.6 dm3

1. Unscrew the screw plug from the back of the pump.

2. Screw in a dial gauge (see fig. Adapter with indicator for setting injection timing) on a special frame.

3. Slowly rotate the crankshaft in the opposite direction to the working direction until the indicator needle stops and set the indicator to zero.

4. Unscrew the screw plug from the engine block and screw in a mandrel 1 in its place to set the crankshaft to TDC position 1 of the cylinder.

5. Slowly turn the engine clockwise until it stops in the mandrel.

6. Rotate the high pressure fuel pump housing until the dial indicator reads 0.92 mm.

7. Tighten the pump fixing bolts in this position.

Engine 1.8 dm3

1. Check whether there is a mandrel in the inspection hole on the side of the engine block for setting the piston of cylinder 1 to TDC.

2. Using the appropriate tool, install the hole in the fuel pump drive pulley against the hole in its housing.

3. Using Torx bolts, attach the front of the fuel pump housing to the engine block.

4. After removing the setting tool, install the pulley on the fuel pump drive flange and lightly tighten the pulley mounting bolts.

5. Position the fuel pump installer in the pulley and make sure it fits into the hole in the fuel pump drive flange.

6. Install the pulley mounting bolts in the middle position of the holes in the pump drive pulley.

7. Slide the toothed belt onto the fuel pump pulley.

8. Loosen the tensioner pulley bolt.

9. After the automatic movement of the tensioner (under the influence of a spring) tighten the tensioner pulley bolt.

10. Tighten the fuel pump pulley bolts to the correct torque.

11. Remove the setting mandrel and tool from the pump pulley and engine block.

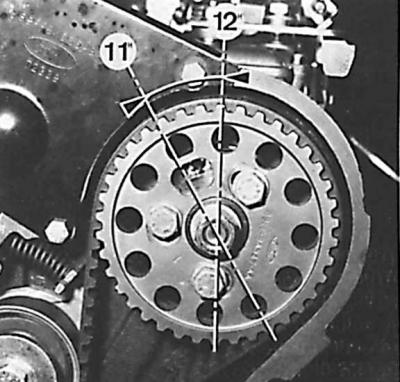

12. Turn the engine crankshaft two full revolutions and set the hole in the fuel pump adjuster to position "12 hours", and the camshaft in position "8 ocloc'k".

13. Rotate the engine crankshaft counterclockwise and set the fuel pump adjusting tool hole to position "11 o'clock".

14. Install a mandrel in the control hole of the engine block for setting the piston of 1 cylinder to TDC and screw it up to the stop.

15. Carefully turn the engine crankshaft until it rests against the locating mandrel screwed into the bore of the cylinder block.

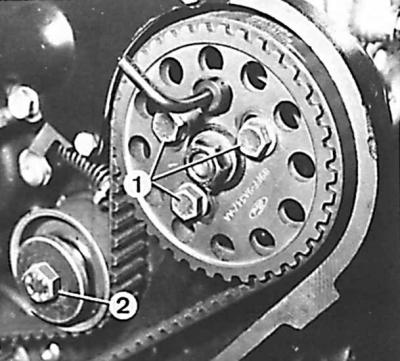

16. Insert the fuel pump installation tools (1 - bolts for fastening the fuel pump pulley, 2 - bolt for fastening the tensioner roller).

17. If it is not possible to insert the fuel pump installer into the fuel pump drive flange, loosen the drive pulley bolts and turn the pulley relative to the flange so that the installer can be screwed in until it stops. Tighten the fuel pump drive pulley bolts and recheck the installation of the pump shaft.

18. Remove all setting tools and mandrel, and insert a plug into the inspection hole of the engine block.

Visitor comments