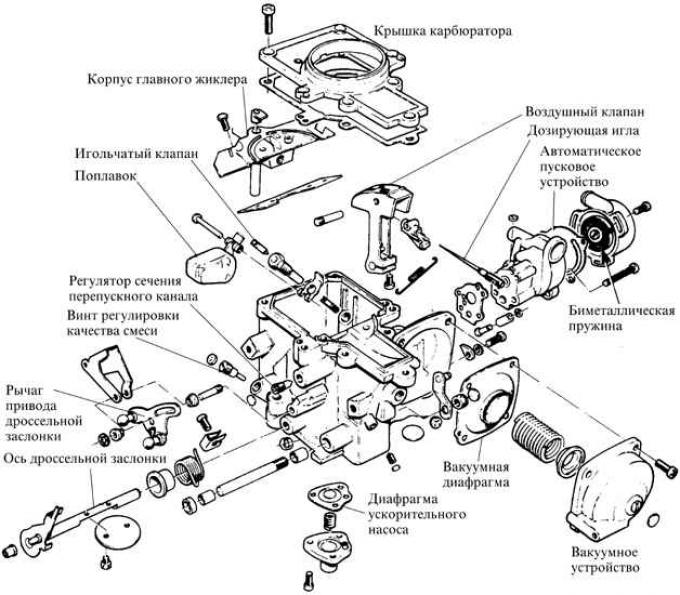

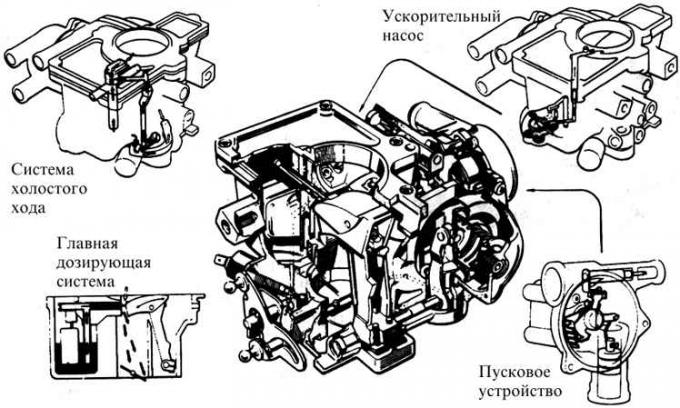

FORD VV carburetor with variable diffuser section

Basic carburetor systems

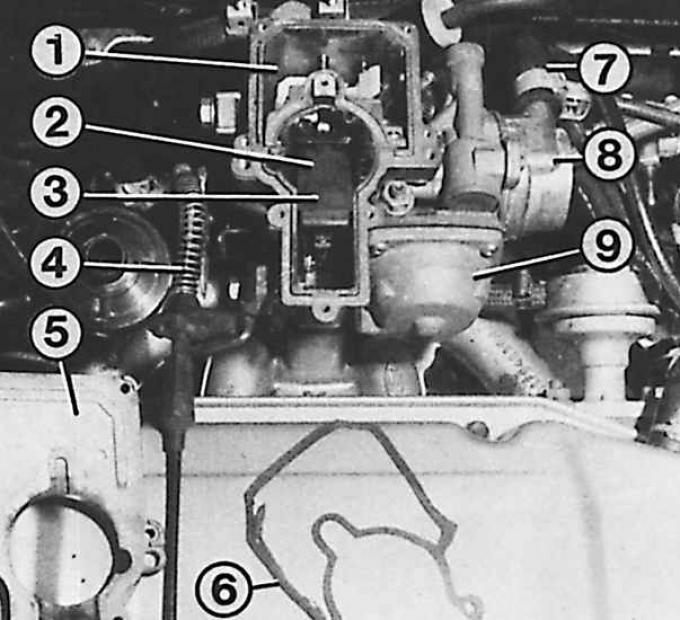

View of the carburetor with the cover removed

1 - float chamber; 2 - dosing needle; 3 - air valve; 4 - accelerator cable; 5 - carburetor cover; 6 - gasket; 7 - hose for supplying coolant to the starting device; 8 - starting device; 9 - vacuum air valve control device

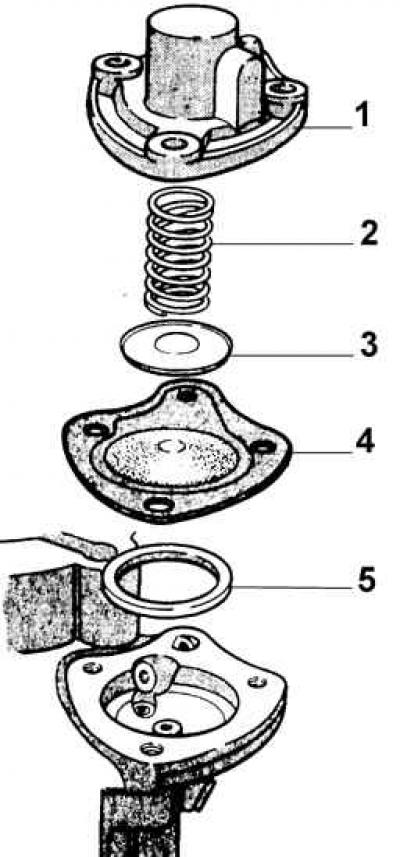

Upgraded accelerator pump

1 - cover; 2 - spring; 3 - plate; 4 - diaphragm; 5 - sealing ring

FORD VV carburetor (Variable Venturi) with a variable diffuser section replaced the previously used fixed jet carburetor. Thanks to the new carburetor, engine power has increased and fuel consumption has been reduced; since it delivers a leaner mixture to the combustion chambers, the percentage of carbon monoxide in the exhaust gases is also reduced.

The Variable Diffuser consists of a spool controlled by a vacuum diaphragm and fitted with a rigidly connected needle that opens the main jet as the spool allows more air to pass through.

The carburetor is also equipped with an idle system, a diaphragm accelerator pump and an automatic starting device with a bimetallic plate.

The fuel supply is controlled by a needle valve and a float in the float chamber. No additional adjustments are required.

The main dosing system of the carburetor consists of an emulsion tube, main and auxiliary fuel jets and a conical dosing needle. The fuel flow is set by vacuum in the carburetor diffuser.

Visitor comments