The control unit receives signals from sensors and selects the ignition timing that is optimal for all operating conditions.

The ignition coil is mounted on the engine and has two primary and two secondary windings. Each of the two secondary windings supplies a spark to two cylinders, of which one ignites the mixture in one cylinder, and the other is fed into the other cylinder during the exhaust stroke.

Knock sensor

Removing the knock sensor

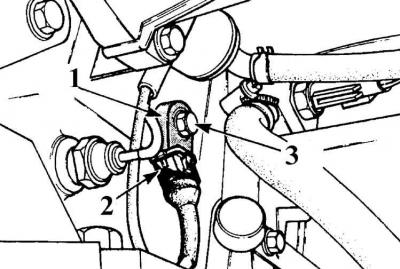

1 - knock sensor; 2 - connector; 3 – a bolt of fastening of the gauge of a detonation

Detonation is a spontaneous explosive self-ignition of the working mixture in the engine cylinders. The knock sensor is mounted on the engine block, registers the vibration of the engine and transmits the corresponding signals to the control unit. When detonation occurs, the control unit sets a later ignition timing, thereby removing detonation. The knock sensor is installed on the cylinder block between cylinders 2 and 3, 10 cm below the intake manifold.

Withdrawal

To remove the knock sensor, disconnect the ground wire, drain the coolant, remove the connector, unscrew the mounting bolt and remove the sensor.

Ignition coil

The ignition coil is checked with an ohmmeter.

| Primary winding resistance: | |

| – contact ignition system, engine 1.1 dm3 up to 12/85 | 1.2 - 1.4 ohm |

| – Contactless ignition system, engines 1.3, 1.4 1.6 in.3 and 1.1 in.3 from 1/86 | 0.72 - 0.88 ohm |

| – contactless ignition system, engine 1.6 dm3 RSi with catalytic converter | no more than 1.6 Ohm |

| Secondary winding resistance: | |

| – contact ignition system, engine 1.1 dm3 up to 12/85 | 5000 - 9000 Ohm |

| – Contactless ignition system, engines 1.3, 1.4 1.6 in.3 and 1.1 in.3 from 1/86 | 4500 - 7000 Ohm |

| – contactless ignition system, engine 1.6 dm3 RSi with catalytic converter | 13500 - 16500 Ohm |

Visitor comments