Input shaft assembly

1. Installation of bearings on the input shaft must be carried out using a sleeve of the appropriate diameter, which must abut against the inner ring of the bearing when pressed.

Attention! When installing a larger bearing, the circlip groove should be at the end of the shaft.

Output shaft assembly

2. Before assembling the output shaft, lubricate all parts with oil used for gearboxes.

3. Fix the output shaft vertically in a vise, on the jaws of which there are soft metal linings. The location of the shaft is with the drive gear of the differential down.

4. Install on the shaft:

- 1st gear gear, synchronizer blocking ring in the direction opposite from the final drive gear, and a retaining ring;

- 1st and 2nd gear synchronizer assembly, shift fork groove towards 1st gear, and a new circlip;

- 2nd gear gear, 2nd gear thrust washers and circlip;

- 3rd gear gear;

- 3rd and 4th gear synchronizer assembly and new synchronizer retaining ring;

- 4th gear gear;

- bearing (press with a mandrel), the circlip groove on the bearing must face outward;

- bearing snap ring.

Differential box assembly

5. Install the speedometer drive gear.

6. Using a suitable mandrel, install the bearings on the differential case.

7. Install the pinion shaft, pinion pins and axle retainer.

8. Insert the side gears into the differential box, install them in their places and fix them with the previously removed plugs. The diameter of the plugs is 22 mm.

9. Install the main gear driven gear on the differential box, with the chamfer directed towards the box and secure it with new bolts, tightening them to a torque of 98–128 Nm.

Gearbox Assembly

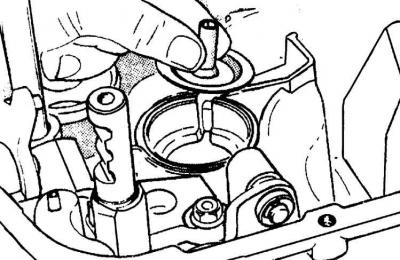

10. Install a new oil slinger and bearing outer ring into the bearing housing of the output shaft of the clutch housing.

11. Install bearing rollers.

12. To caulk evenly around the perimeter of the outer ring of the bearing for a clear fixation of the latter.

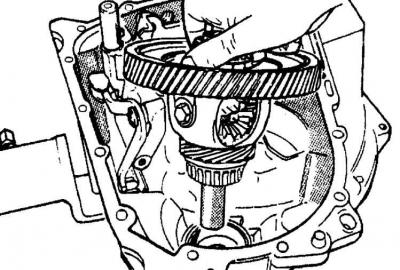

13. Install the differential box with the speedometer drive to the clutch housing.

14. Install the movable reverse gear with the gear drive in the groove on the gear hub.

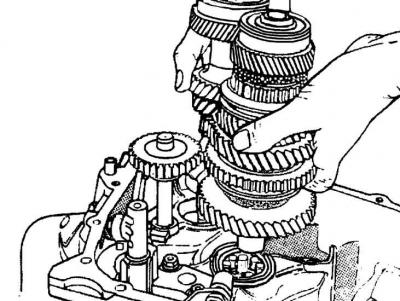

15. Fold the primary and secondary shafts, aligning the gears and install in a single block in the crankcase, while moving the reverse gear over the 1st gear.

16. Install the drive axle spring into the crankcase seat.

17. Install the retainer and shift forks.

18. Align the holes for the fork axle and insert the axle with the extended groove side into the clutch housing.

19. Perform a gear change test. Gears should shift easily and without jamming. Engage 4th gear, which is necessary to adjust the gear selection mechanism after installing the gearbox on the car.

20. Install the magnet in the socket.

21. Install the outer race of the bearing in the gearbox housing, after placing two special washers. The washers are mounted with their convex sides facing each other, with the larger diameter washer resting against the outer ring of the bearing. Caulk the outer race of the bearing evenly around the perimeter in several places.

22. Install the gasket to the clutch housing and install the transmission housing. You can use a mallet to plant the crankcase of the box.

23. Insert and alternately tighten the bolts connecting the clutch and gearbox housings.

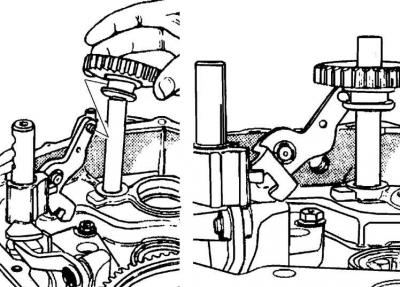

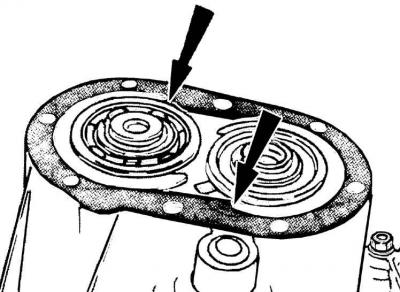

24. Install retaining rings (indicated by arrows) fixing the bearings, having previously selected their thickness so that they fit into the grooves without clearance.

25. To facilitate installation of the retaining rings, you can move the shafts up with a screwdriver or other tool. Rotate the notches on the circlips so that they do not overlap with the cover gasket.

26. Install the gasket and cover on the gearbox housing.

27. Install the clutch release shaft, fork and release bearing.

Visitor comments