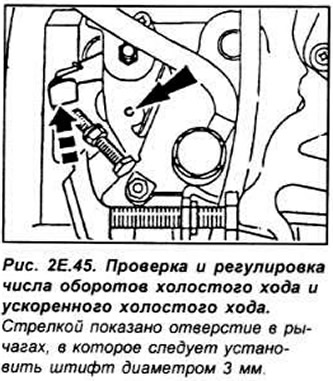

turn the lever "STOP" clockwise until such a position that the hole in the levers (arrow on. rice. 2E.45) it was possible to insert a pin with a diameter of 3 mm.

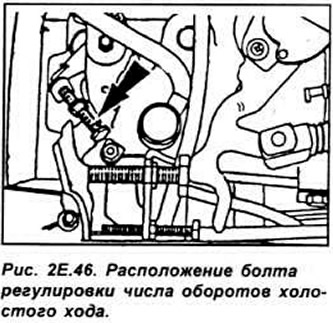

By turning the minimum portion adjustment bolt, adjust the engine speed to 900±100 rpm.

Remove the 4 mm thick plate and the 3 mm pin.

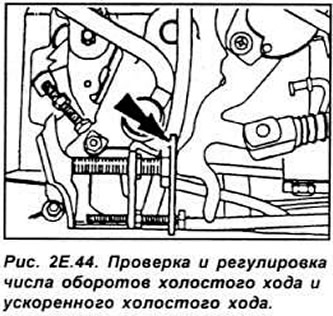

Turning the idle speed screw (see fig. 2E.46) set the engine speed to 850±50 rpm.

Increase the engine speed to maximum, then release the boost lever on the fuel pump and check the time from maximum to idle (maximum 5 seconds) If the speed drops too much or the engine stops, proceed as follows.

If the engine stops, unscrew the minimum portion adjustment bolt a quarter of a turn (turn counterclockwise looking at the rear of the fuel pump) and repeat the idle speed reduction time measurement.

If the reduction time exceeds 5 seconds, screw in the minimum dose adjustment screw (turn clockwise looking behind the fuel pump) and repeat the idle speed reduction time measurement.

Attention. Do not turn the bolt more than a quarter of a turn in both directions.

Visitor comments