Withdrawal

Disconnect the ground wire from the battery. Peel off the spring hooks securing the upper casing of the timing system drive. Place the vehicle on a stationary lift. Unscrew the bolt securing the lower toothed belt casing, then loosen the second bolt and turn the casing down around the loosened bolt. Lower the vehicle and remove the upper timing cover. Mark the position of the accelerator pedal cable on the fuel pump lever and unhook the cable from it. Unscrew a bolt of fastening of the lever and take a cable.

Disconnect the electrical wire connector from the cold engine injection advance corrector. Disconnect from the pump the connectors of the injection pipelines and the connectors of the return pipelines and the fuel dose corrector (close the openings with appropriate plugs or caps).

Unscrew bolts of fastening of bracket of the lower arm of the fuel pump. Unscrew bolts of fastening of a bracket to the block of cylinders of the engine. Disconnect the electrical connector of the engine shutdown solenoid valve (STOP valve). Carefully disconnect the vacuum line between the turbocharger pressure correction valve and the intake manifold. Remove the alternator drive belt.

Remove the control hole plug from the engine block to install the piston of 1 cylinder at TDC.

Disconnect the fuel, return and turbocharger pressure correction lines. Using the appropriate wrench, turn the crankshaft pulley clockwise so that the fuel pump is in position "12 hours" (see fig. 2E.11). and the cutout of the camshaft in position "8 ocloc'k".

Turn the engine crankshaft counterclockwise to set the fuel pump to position "11 o'clock" (see fig. 2E.11)

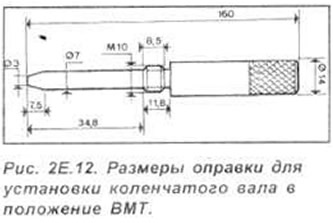

Screw the mandrel all the way (see fig. 2E.12) for setting the piston of 1 cylinder to TDC (see fig. 2E.13).

Loosen the bolt (2. fig. 2E.14) fastening the tensioner roller of the timing belt of the fuel pump drive, loosen the toothed belt and tighten the bolt of the tensioner roller. Remove three screws (1. fig. 2E.14) fastening the fuel pump pulley. Remove the timing belt and fuel pump pulley. Remove the fuel pump from the engine block.

Installation

Attention When installing a new fuel pump, remove the plugs (plugs), blocking the openings of the fuel pipes and pour diesel fuel into the pump to facilitate the removal of air from it.

Check whether there is a mandrel in the inspection hole on the side of the engine block for setting the piston of cylinder 1 to TDC. With the appropriate tool (see fig. 2E.14) install the hole in the fuel pump drive pulley against the hole in its housing.

Using Tox bolts, attach the front of the fuel pump housing to the engine block.

After removing the setting tool, install the pulley on the fuel pump drive flange and lightly tighten the pulley mounting bolts. Position the fuel pump installer (see fig. 2E.14) in the pulley and make sure it fits into the hole in the fuel pump drive flange. Install the pulley mounting bolts in the middle position of the holes in the pump drive pulley (see fig. 2E.14).

Slide the toothed belt onto the fuel pump pulley. Loosen the tensioner pulley bolt.

After the automatic movement of the tensioner (under the influence of a spring) tighten the tensioner pulley mounting bolt. Tighten the fuel pump pulley bolts to the correct torque.

Remove the installation mandrel and tool from the pump pulley and engine block. Turn the engine crankshaft two full revolutions and set the hole in the fuel pump adjuster to position "12 hours" (see fig. 2E.11), and the camshaft is in position "8 ocloc'k". Rotate the engine crankshaft counterclockwise and set the fuel pump installer hole to position "11 o'clock" (see fig. 2E.11).

Install a mandrel in the control hole of the engine block to install the piston of 1 cylinder at TDC and screw it up to the stop. Carefully rotate the crankshaft of the engine until it rests against the mounting mandrel screwed into the hole in the cylinder block. Insert the fuel pump installation tools. If it is not possible to insert the tool for installing the fuel pump into the flange of the fuel pump drive, then loosen the bolts securing the pulley of its drive and turn the pulley relative to the flange so that the installation tool can be screwed up to the stop. Tighten the fuel pump drive pulley bolts and check the pump shaft installation again. Remove all installation tools and mandrel, and insert a plug into the inspection hole of the engine block Install the rear bracket bracket to the fuel pump and tighten its mounting bolts to the appropriate torque. Check that the fuel pump is properly attached. Screw the fuel line connectors to the pump (return injection, fuel supply and fuel dose regulator).

Connect the accelerator pedal cable in accordance with the designation made in the process of disconnecting it.

Connect the connectors of the electrical wires of the engine shutdown solenoid valve (STOP valve) and a cold engine injection advance corrector.

Establish the top casing of a gear belt of a drive of system timing.

Raise the car, turn the lower casing of the toothed belt of the timing belt up, insert the mounting bolt and tighten it and the bolt that serves as the axis of rotation of the casing.

Put on the alternator drive belt and tension it. Lower the vehicle and tighten the upper timing cover bolt. Remove air from the fuel system.

Visitor comments