Replacement of a forward sealing ring of a cranked shaft

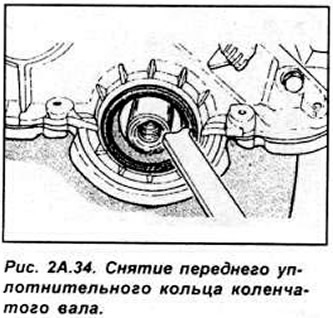

Remove the ground wire from the battery. Loosen the lower mounting bolts and the upper tension bolt of the alternator, tilt the alternator towards the engine and remove the drive belt. Unscrew the pulley mounting bolt on the crankshaft, for which it is necessary to fix the engine flywheel, after removing the lower clutch cover or starter, for free access to the flywheel. Remove the pulley from the crankshaft. Using a suitable claw type tool, remove the crankshaft front O-ring (see fig. 2A.34).

Thoroughly clean the O-ring seat. Install a new sealing ring and pulley on the crankshaft journal and, screwing the pulley mounting bolt, press the sealing ring into the socket.

Unscrew the pulley mounting bolt again, remove the pulley and apply a layer of lubricant to the surface of the pulley in contact with the sealing ring, then install the pulley in place and secure with the bolt. Install the lower clutch cover or starter. Install the alternator drive belt and adjust its tension. Connect ground wire to battery.

Replacement of a back sealing ring of a cranked shaft

Remove flywheel.

Using a suitable claw type tool, remove the crankshaft rear O-ring. Thoroughly clean the O-ring seat.

One of two possible methods can be used to install the O-ring, depending on the tools available. With Ford tool 21-011, lubricate the crankshaft flange and O-ring seal lips with clean engine oil. Install the o-ring into the tool, then press the o-ring into the housing.

In the absence of a special device. remove the sump then unscrew the bolts securing the rear seal seat and remove the seal seat from the cylinder block. New gaskets must be used for the seal seat and sump when reinstalled. Thoroughly clean the O-ring seat and mating surfaces of the sump and crankcase. Install the new o-ring straight into the casing, place a flat bar across the o-ring, and press the o-ring into the casing. Lubricate the crankshaft flange and the inner lip of the O-ring with clean engine oil, and install the casing with a new gasket on the cylinder block and fasten with bolts (see fig. 2A.35, 2A.36).

Check that the mating surfaces of the crankshaft and flywheel are clean. then install the flywheel.

Visitor comments