During the test, the power unit should be raised slightly to take the load off the suspension. Raise the front of the car and secure it on stands.

Place a jack under the oil pan with a bar between the jack head and the sump and raise the power unit just enough so that the weight of the power unit is supported by the jack.

Check the condition of the suspension of the power unit for wear of rubber bushings and the connection of rubber and metal elements.

Check for relative movement between the suspensions of each installation and the power unit. If there is movement, lower the engine and check the machine's suspension under load.

The powertrain suspension can be removed if the weight of the powertrain is supported by one of the following alternative methods.

Support the weight of the power package from below using a jack with a block between the jack head and the sump, and raise the power package just enough so that the weight of the power package is supported by the jack, or by lifting the engine with a winch.

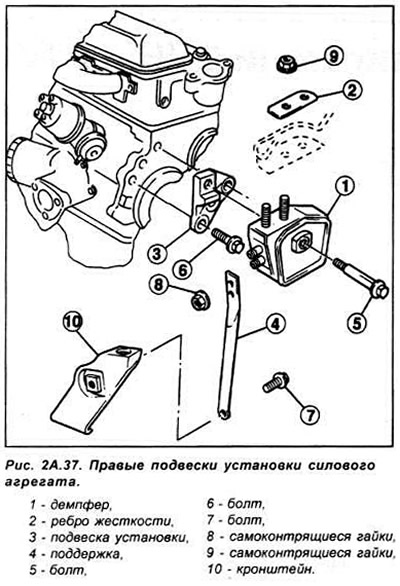

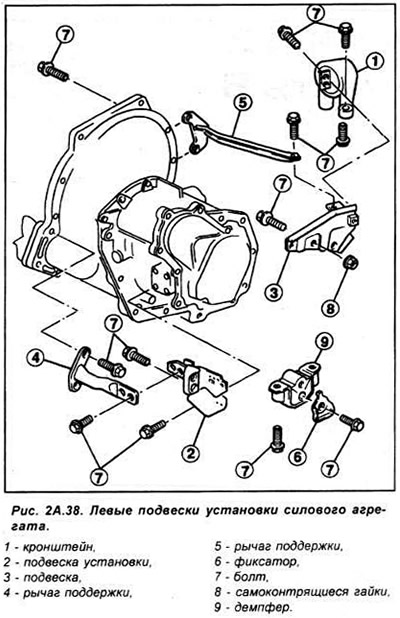

After accepting the weight of the power unit by the lifting mechanism, you can unscrew the mounting bolt of any of the suspensions and replace the suspension. When replacing a suspension, pay attention to the location and orientation of the suspension and any associated parts (see fig. 2A.37, 2A.38).

Reinstallation to the original place of the suspension is carried out in the reverse order of removal. Check that all previously removed washers are in place.

The final tightening of the fastening bolts should be made after installing all the supports in place, while the rubber parts should not be twisted or strongly stretched.

Visitor comments