Attention. Valve clearances are checked and adjusted only on a cold engine.

The correct setting of valve clearances is very important, as they largely determine the operation of the engine. If the valve clearances are too large, the engine will be noisy and the efficiency of the engine will be reduced as the valves open too late and close too early. A more serious problem occurs if the valve clearances are too small, as the valves cannot close fully on a hot engine, which can cause serious engine damage.

Set the piston of the first cylinder to TDC on the compression stroke.

Remove the cylinder head cover.

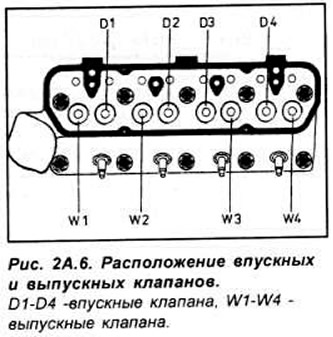

Counting from the thermostat on the cylinder head, the valves are arranged as follows.

| Valve number | Cylinder number |

| 1 - Graduation | 1 |

| 2 - Inlet | 1 |

| 3 - Graduation | 2 |

| 4 - Inlet | 2 |

| 5 - Inlet | 3 |

| 6 - Graduation | 3 |

| 7 - Inlet | 4 |

| 8 - Graduation | 4 |

Adjust valve clearances in the sequence given in the following table. Rotate the crankshaft pulley 180°after adjusting each pair of valve clearances.

| Rocker valves | Adjustable valves |

| 7 and 8 | 1 (high school graduation), 2 (inlet) |

| 5 and 6 | 3 (high school graduation), 4 (inlet) |

| 1 and 2 | 8 (high school graduation), 7 (inlet) |

| 3 and 4 | 6 (high school graduation), 5 (inlet) |

Use a feeler blade of the appropriate thickness to check each gap between the end of the valve stem and the rocker arm. The feeler gauge should fit snugly between the valve and rocker arm. For adjustment, it is necessary to turn the regulator bolt with a spanner wrench until the required clearance is obtained. The adjuster bolts are of the rigid thread type and do not require the use of a locknut (see fig. 2A.7).

Finally install the cylinder head cover.

Visitor comments