SEQUENCE OF WORK

1. Raise the vehicle in a level and level position and secure it on stands. Remove the rear wheel.

2. Remove the protective cover from the parking brake lever and lift up the lever.

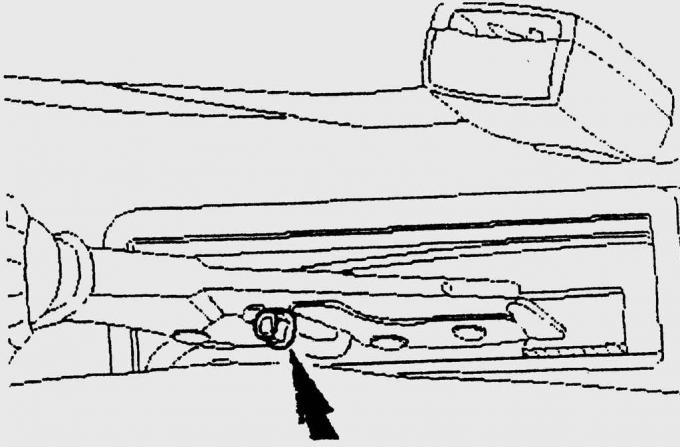

Pic. 14.22. Location of the parking brake cable adjusting nut

3. Fully release the parking brake lever retainers and unscrew the parking brake cable adjusting nut (pic. 14.22).

4. Carefully remove the wheel hub cap, use a hammer and chisel if necessary. Replace the damaged cover with a new one.

5. Loosen the wheel hub nut and remove the spin washer.

6. Remove the brake drum from the wheel hub. If necessary, while turning the brake drum, tap its circumference with a rubber mallet. In auto repair shops, special pullers are used to remove drums.

7. Check the brake drum for wear, cracks and deep scratches.

8. Thoroughly clean the brake drum with sandpaper. Clean the rear brake guard with a clean brush and alcohol and dry with compressed air. Use a respirator as brake dust is easily inhaled. Remove dust from brake pad wear with a vacuum cleaner.

PRACTICAL ADVICE

Brake pad replacement tips

1. Before removing, be sure to mark the installation position and the location of individual parts - this is necessary primarily for springs. So you will facilitate the assembly process and eliminate the possible occurrence of malfunctions in the future.

2. If you are working on both sides of the rear axle at the same time, do not confuse the location of the parts of the left and right brake mechanisms.

3. When the brake pads are removed, never press the brake pedal, as otherwise you will squeeze the pistons out of the wheel brake cylinder. For safety, secure the pistons with a clamp.

4. With the brake pads removed, always check the tightness of the wheel brake cylinders. To do this, carefully lift the protective covers: if you notice moisture, remove the cylinder and have it repaired by a car workshop or replace it with a new one. As practice shows, in this case, check the tightness of the wheel brake cylinder on the other side of the rear axle.

PRACTICAL ADVICE

Boring of brake drums

The inner diameter of the new brake drums is 180 mm. If deep scratches have formed on the inner surface of the drum, the workshop can grind or bore the brake drum. When worn to a diameter greater than 181.5 mm, the brake drum must be replaced. As a rule, the simultaneous application of the brakes assumes the same inner diameter of both brake drums, so always have both brake drums bored.

Visitor comments