SEQUENCE OF WORK

1. Rotate each wheel one turn. Carefully remove stones and other foreign objects from the tread. If a chip or nail is lodged in the tire, the tire carcass may be damaged. If air does not come out of the tire, have the wheel checked by a specialist.

Pic. 13.37. Carcass crack visible on the inside of the tire

2. Pay attention to deviations, such as punctures, cuts, cracks or torn pieces of the profile. If a defect is found after a long time, the tire carcass may be seriously damaged by driving with low tire pressure for a long time (pic. 13.37). If moisture has penetrated the puncture and reached the metal cord, corrosion can seriously weaken it.

3. The tire tread profile must protrude at least 1.6 mm above the tire surface. The thickness of the profile can be determined by various criteria. Wherever there are letters on the sidewall of the tire «TWI» (tread wear indicator), the grooves of the tire form a height of 1.6 mm with the transverse strips. As soon as the transverse strips are level with the working surface, the tire must be replaced, as the car's behavior deteriorates with a decrease in the tire tread profile, especially in wet weather. Replace summer tires with new ones with a tread height of at least 2.0 mm. Winter tires should be changed at a tread depth of about 4.5 mm.

4. Check up uniform wear of all tires.

5. Carefully inspect the sidewalls of the tires. Blisters indicate damage to the framework.

TECHNICAL DICTIONARY

Wheel balancing

Balanced wheels are installed on the car. During the operation of the car under the influence of various reasons, the balance of the wheels can be disturbed, which is manifested in the vibration of the steering wheel.

Wheel imbalance leads to increased wear on the steering parts, tires and suspension of the car, so if it occurs, the wheels should be rebalanced. Steering wheel vibration due to wheel imbalance occurs in a certain speed range and disappears when the speed decreases or increases. In addition, wheel balancing is necessary after mounting a new tire and after each tire repair.

Static wheel imbalance

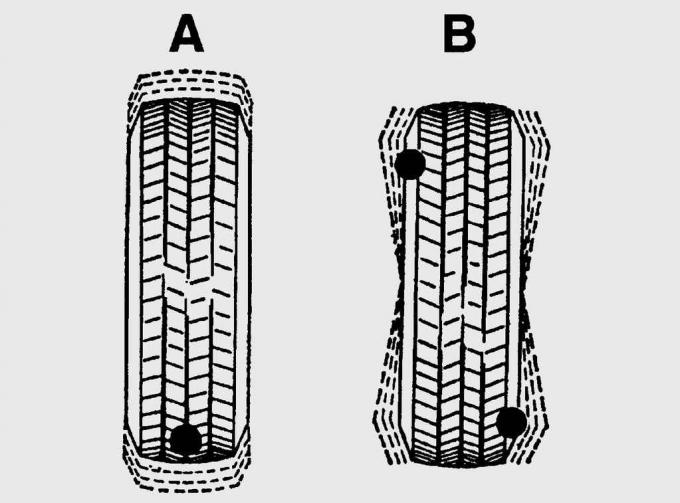

Pic. 13.38. Directions of wheel movement at static (A) and dynamic (IN) imbalance

(pic. 13.38, A) manifests itself in the fact that the masses of individual parts of the wheel relative to the axis are different. In this case, if you install the wheel on a freely rotating axle, then it will turn so that the heavier part of the wheel will always be at the bottom. A wheel with a static imbalance may bounce when the vehicle is moving, which will lead to rapid wear of the shock absorber.

Wheel dynamic imbalance

(pic. 13.38, V) determined only when the wheel is spinning fast. The heavier part of the wheel is located laterally relative to the average section of the wheel and, when the wheel rotates, leads to its rocking, which causes accelerated failure of the hub bearing and suspension elements.

TECHNICAL DICTIONARY

Tire wear

Wear on the outside of the front tires indicates overcoming curved sections of the road at high speeds. In this case, to eliminate further such tire wear, turn the tires on the rims or swap the front and rear wheels.

The wear on the outer edges of the tire is greater than the central part of the cross section indicates that the vehicle has been driven for a long time with a tire pressure that is too low.

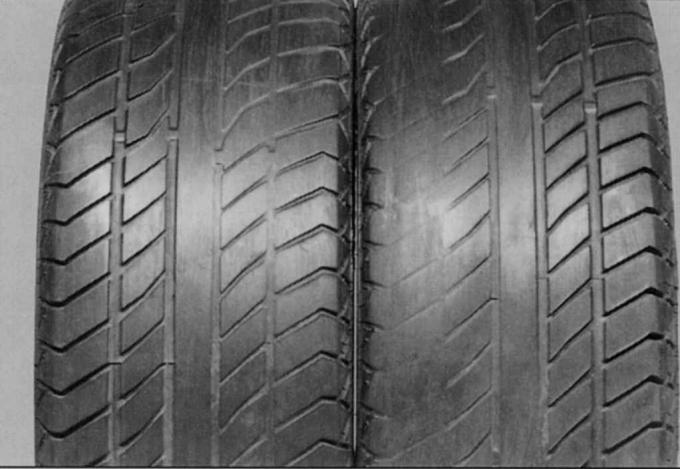

Pic. 13.39. Unilateral tire tread wear. Incorrect wheel alignment not only causes increased tire wear, especially one-sided wear, but also contributes to a decrease in traffic safety

Unilateral tire cross-section wear indicates incorrect wheel alignment, especially when only one tire has such wear (pic. 13.39).

Pic. 13.40. Severe wear in the middle of the tire tread profile. It occurs due to the frequent movement of the car at maximum speed, as a result of which, due to the action of centrifugal forces, the tire tread becomes convex in the center and wears out intensively. This type of wear is especially common on the rear wheels (at elevated pressure)

Increased wear in the middle of the cross section occurs when the car is moving at high speed, at which the central part of the tread bends outward under the action of centrifugal force. This effect is especially pronounced on the rear wheels. This wear can also indicate high tire pressure (pic. 13.40).

Uniform local wear in the cross section indicates a failure of the shock absorber.

Uneven wear in certain areas only appears when the wheel balance is disturbed or the tire carcass is damaged.

Pic. 13.41. Location of tire wear due to lock-up braking of a vehicle without ABS

Strong wear of a single point in the cross section comes from wheel-lock braking of vehicles without anti-lock brakes (pic. 13.41).

PRACTICAL ADVICE

Tire storage

After changing summer or winter tires, they must be stored properly. For this, a dry, cool and dark room is best suited. Keep gasoline, oil, and other chemicals away from tires, as their vapors, even in small quantities, imperceptibly destroy rubber.

First, mark the direction of rotation and the position of the tires with chalk: VR (PP) – front right, VL (PL) – front left, HR (RFP) – rear right, HL (ZL) - back left.

Remove tires, rinse with water and dry well. Clean the tread grooves of all foreign objects.

Store the wheels on top of each other, preferably on an old pallet.

Store tires without rims in an upright position, rotating them from time to time.

Visitor comments