SEQUENCE OF WORK

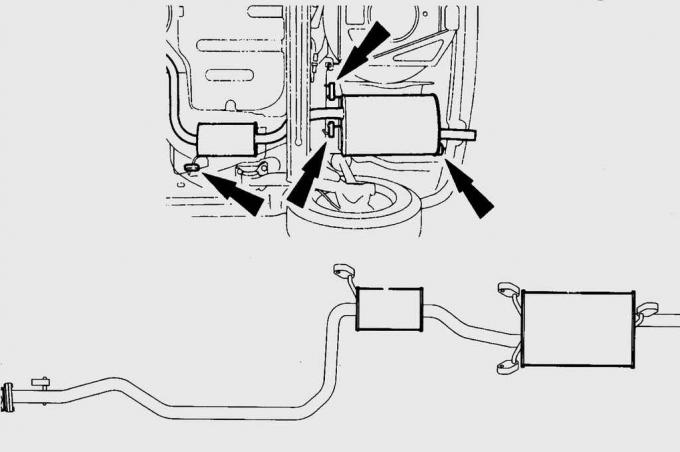

Pic. 11.1. The location of the rubber supports for fastening the exhaust system to the bottom of the car

1. Check rubber mounts for brittleness, cracks or other defects and replace if necessary (pic. 11.1).

2. To check, move the exhaust pipe to the left and right near the rubber supports.

3. Check the tightness of the bolt connections of the exhaust system, exhaust manifold and brackets, but do not use excessive force, which may damage the parts.

4. Plug the end of the exhaust pipe with a rag while the engine is running. After a short period of time, the engine should stop. If you hear a hiss and the engine continues to run unhindered, this means that the exhaust system is leaking.

5. A duller-than-usual exhaust sound and crackling when moving the exhaust pipe indicates corrosion of the exhaust system.

6. Thoroughly tap the removed serviceable muffler with a hammer. Do not strike at an angle to the muffler surface. If a ringing sound is heard with each impact, this means that the metal has not yet been damaged by corrosion. If in some places the sound from blows becomes muffled, then the outer shell is already weakened by corrosion and will soon burn out, especially in the winter season, when salt is scattered on the road surface.

Visitor comments