V-belt - it all depends on its pre-tension

V-belts only perform satisfactorily if they have the correct pretension. They should be tight, but not too tight. Normally, if the sag when pressed is 3-5 mm. Tight belts will eventually destroy the bearings of the generator, water pump (depending on engine type) and air conditioning compressor. In addition, V-belts that are too tight stretch and can then break. On the contrary, loosely tensioned V-belts slip - this is noticeable by an unpleasant squealing sound. The alternator suffers the most from this, as it does not provide enough charging current, which puts an undue strain on the battery, especially when driving short distances and when starting a cold engine. The V-belt itself is also damaged, its sides burn out.

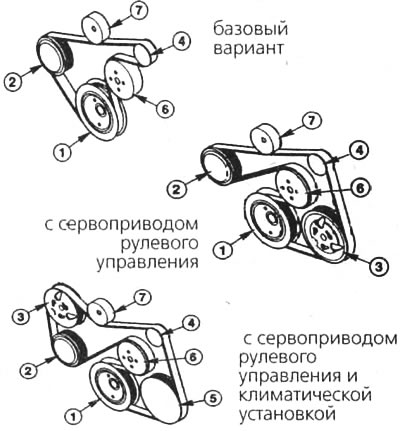

Zetec-SE engines always use 6K-Poly-V belts: they have different sizes depending on the configuration. A hydraulic device adjusts the belt tension. 1 - crankshaft; 2 - hydraulic belt tensioner; 3 - steering servo pump; 4 - generator; 5 - air conditioning unit; 6 - water pump; 7 - guide roller.

Consequence: premature wear. In extreme cases, slipping V-belts can even lead to excessive engine overheating and. hence costly damage (e.g. piston seizure, burnt cylinder head gasket). Although your Focus automatically adjusts the V-belt tension, take a focused look at this gear from time to time.

Stages of work

Check the surface of the belt.

Turn the engine over by hand several times. This is the only way you can reliably check the V-belt. Often there is one deep crack in the V-belt. And if, unfortunately, during the test, the crack is adjacent to the belt pulley, then, despite the test, damage is preprogrammed.

Replace the V-belt if you find the following damage on it:

- uneven wear marks on the sides of the belt,

- porous, disheveled edges of the belt or its surface,

- age cracks.

Visitor comments