General information

Minor dents can be repaired without damaging the paintwork. The dent is removed from the inside using special dressing tools. The prerequisites are that there is a specific diagnosis, that the correct repair method is determined, and that the technician has sufficient experience in the use of special tools and knowledge of the working materials.

- This option is limited to those body surfaces that are accessible from both sides. This repair technique is rarely used on double-skin or closed body sections. The same applies to the extreme areas, edges and folds of body elements with increased rigidity.

- Satisfactory results are only possible for minor dents that are small and have a small deformation radius. Therefore, this method is particularly suitable for damage caused by hail during parking and transport.

Economic Considerations

Whether it is economical to repair dents without damaging the paintwork depends on:

- Area and depth of the dent.

- Access to the repair area.

- Rigidity of the repair zone.

- Material suitability

- The number of dents in a particular section of the body panel.

- Is there any damage to the paintwork already?

Damage extent

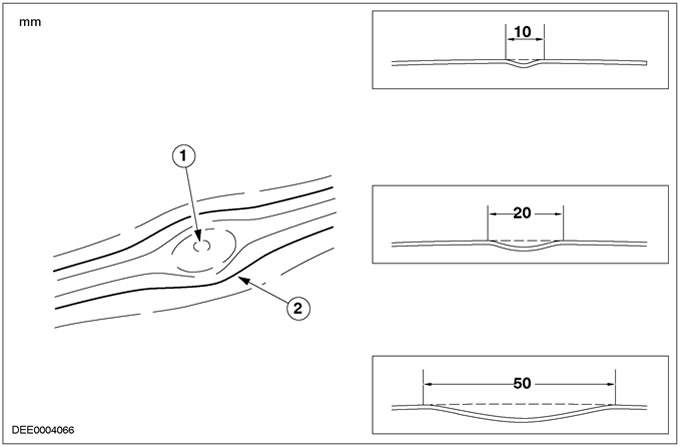

The repair method is suitable for dents up to approximately 50 mm in diameter.

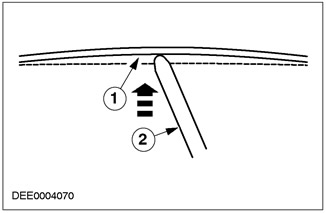

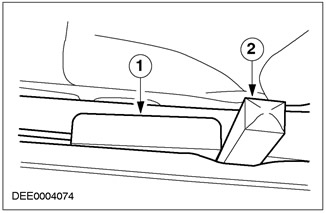

Damage assessment according to the size of the dent

| Pos. | Spare Part No | Name |

| 1 | - | center of the dent |

| 2 | - | Dent edge |

Prerequisite for repair

The material in the center of the dent must not be stretched.

Repair procedure

- Run diagnostics on the damaged area.

- Note the dent.

- Prepare the area to be repaired.

- Set the adjustable lamp to the required position.

- Restore the original shape of the dent.

- Replace the corrosion protection material.

- Perform a quality check.

Repair tools / facilities

- Special dressing tools for dent removal

- adjustable lamp

Repair procedure

1. Stop at the repair technique.

2. Mark the dent

NOTE: Do not use a marker containing solvent (paintwork damage).

- The dent is marked in the repair area to make it easier to recognize.

3. Prepare the repair area

- You should make sure that the inside of the dent is accessible. Repair holes should not be made.

- Clean the damaged area of the body. A good visual inspection is essential for a positive result.

- Polish the repaired surface if it is matte. The repair procedure can only be accurately checked if there is sufficient light reflection.

4. Set the adjustable lamp to the desired position.

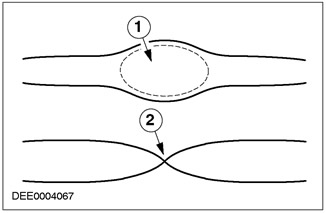

- The dimmable lamp should be positioned and adjusted so that the dent can be clearly seen in the reflection on the paintwork (oval shape).

- With increasing pressure on the dent, the oval shape turns into lines that intersect each other. The point where the lines intersect is the pressure point for the dressing tool.

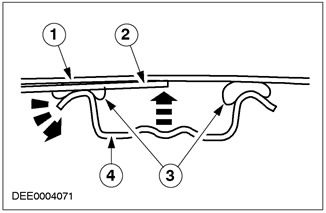

Reflection of light when pressed

| Pos. | Spare Part No | Name |

| 1 | - | No pressure on the dent |

| 2 | - | Pressure applied to the dent |

5. Location of dressing tool

- Position the tip of the dressing tool on the edge of the dent.

- By moving back and forth with light pressure applied to the dent with the tip of the tool, the reflected light indicates the position of the dressing tool.

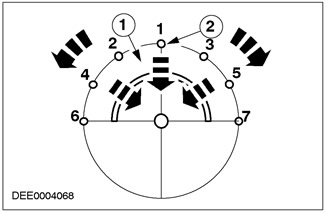

6. Operating principle when pressure is applied

- The work is reduced to the formation of a semicircle, while working chronologically.

- To restore the surface, all that is needed is to work on one half of the dent.

- The unused half of the dent recovers by itself, due to the tension created by the pressure.

Scheme

| Pos. | Spare Part No | Name |

| 1 | - | Pressure sequence |

| 2 | - | Initial position |

NOTE: Never start from the center of a dent. If you start working from the center of the dent, the edge will be raised and remain visible as a high area (material stretching). This raised edge can only be restored after extensive rework.

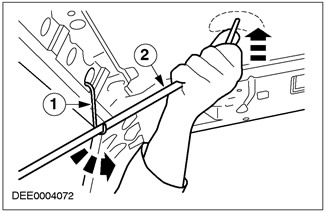

High end

| Pos. | Spare Part No | Name |

| 1 | - | high edges |

| 2 | - | dressing tool |

Exception:

- Sharp-edged dents with minimal material stretch are first flattened in the center.

- After pressing out the dent, slightly convex areas can be seen. This is caused by excess steel in the center of the dent due to material stretching.

- Use a plastic punch to straighten out the slightly raised area.

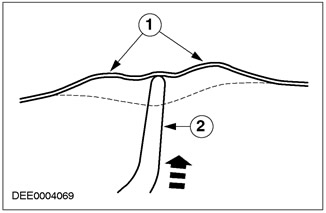

Zone of unstable pressure

When working with large, relatively weak areas of the body, the trajectory of the dressing tool when pressure is applied is correspondingly larger. The recovery process will take longer.

Dent with a large area

| Pos. | Spare Part No | Name |

| 1 | - | Shape Recovery Trajectory |

| 2 | - | dressing tool |

Stable pressure zone

NOTE: Treat areas near the internal reinforcement with light pressure only, so that high zones do not form (material stretching).

Pressure-stable areas of the body with internal bracing have a much more stable surface than low-pressure areas. Only short pressure movements are required here because the body steel is less springy.

Be careful when performing the pressing procedure if you are using a tool with a small contact surface.

Optical check:

- It is only possible to completely remove any remaining unevenness by making continuous visual inspections of the surface using an adjustable lamp. Also, towards the end of the dressing procedure, the dent should be checked several times from different directions. To do this, change the position by about 90°.

Extrusion of a dent near the connection

| Pos. | Spare Part No | Name |

| 1 | - | roof surface |

| 2 | - | dressing tool |

| 3 | - | sealant roller |

| 4 | - | Roof connection |

Support (turning point) dressing tool using S-hook

| Pos. | Spare Part No | Name |

| 1 | - | Turned using S-hook |

| 2 | - | dressing tool |

- To make it possible to apply force in the roof area, an S-hook shaped support should be used.

- Release the headlining only in place, depending on the number of dents and their location.

- Dents near internal elements can be accessed by removing the element (interior lamp).

- Check accessibility before starting repair if the dent is near the sunroof.

- Repairs near internal connections are made using special tools included in the tool kit.

- Remove the bead of sealant on the link using a metal spatula so that the dressing tool can be inserted into the required position.

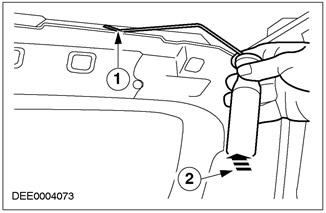

Special lever for dents near internal ties

| Pos. | Spare Part No | Name |

| 1 | - | point of contact |

| 2 | - | Travel direction |

Door zone

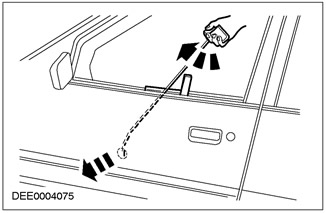

- Dents in the top half of the door can usually be repaired without removing the trim.

- When the window is open, access is provided through the window cavity. To prevent damage to the window, a protective block should be inserted into its cavity.

- A plastic wedge provides access.

Equipment

| Pos. | Spare Part No | Name |

| 1 | - | Protective block |

| 2 | - | plastic wedge |

The pressure in this case is applied without the use of additional support, simply by turning the bent dressing tool.

Pressing out a dent through the window channel

Hood

- The hood moves into position using telescopic stops and is held in the desired position using «rubber cords».

- In the bond area, the sealant bead should be partially opened using a metal spatula to allow access to the dent.

Restoration of corrosion protection

All repaired interior areas should be finalized, where access is available, the paintwork should be restored.

- Clean the interior area using a silicone remover.

- Prime and paint the interior repair area.

- Finally, to places where repair is not possible (No access), inject cavity protection material.

Quality control

To ensure a quality repair that meets factory standards, the following points should be observed:

- Check the repair area for irregularities. Do this optically, looking at the surface from different angles.

- Paint the repaired surface area, clean it and polish it if necessary.

- Check that the connected components and interior trim are installed correctly and that they are not damaged.

Visitor comments