|

STATES |

DETAILS/RESULTS/ACTIONS |

|

A1: FUEL GAUGE TEST |

|

|

1 Activate instrument cluster self-test number one, pointer sweep. |

|

|

• Does the fuel gauge needle go through full sweep? |

|

|

→ Yes |

|

|

Go to A2 |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

A2: ENSURE FUEL GAUGE FAULT |

|

|

1 Drive the ON position. |

|

|

• The fuel gauge shows the level below the position «empty tank» (default position)? |

|

|

→ Yes |

|

|

Go to A3 |

|

|

→ No |

|

|

Go to A7 |

|

|

A3: CHECK FOR CURRENT FAULT |

|

|

1 Activate instrument cluster self-test number 10, fuel volume input test. |

|

|

• Is the output value equal to or less than F010? |

|

|

→ Yes |

|

|

There is a short circuit on «mass» - Vehicles with a non-adaptive fuel system. Go to A17 |

|

|

There is a short circuit on «mass» - cars with adaptive fuel system. Go to A4 |

|

|

→ No |

|

|

If the output value is between F011 and F254, there is a valid input signal. Go to A7 |

|

|

If the output value is F255, there is an open circuit or a short to battery voltage - vehicles with a non-adaptive fuel system. Go to A13 |

|

|

If the output value is F255, there is an open circuit or a short to battery voltage - vehicles with adaptive fuel system. Go to A8 |

|

|

A4: CHECK FOR SHORT CIRCUIT TO « MASS » FUEL TANK SENSOR ELECTRICAL CIRCUIT |

|

|

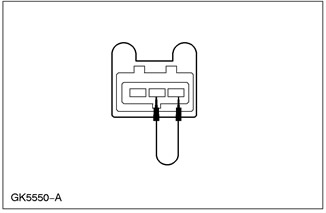

1 Disconnect the C732 fuel pump module. |

|

|

• Does the fuel input value change to F255? |

|

|

→ Yes |

|

|

Install a new fuel pump module. See Section 310-01 for more information. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to A5 |

|

|

A5: CHECK FOR SHORT CIRCUIT ON « MASS » ADAPTIVE FUEL MODULE ELECTRICAL CIRCUIT |

|

|

1 Disconnect the C21 adaptive fuel module. |

|

|

• Does the fuel input value change to F255? |

|

|

→ Yes |

|

|

INSTALL a new adaptive fuel module. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to A6 |

|

|

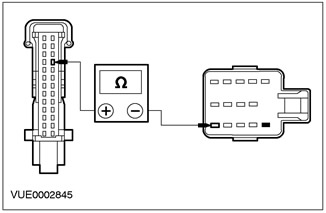

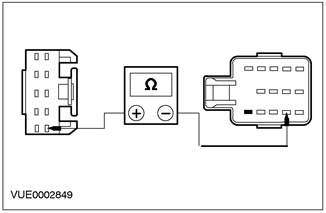

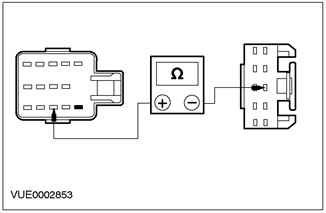

A6: 8-GA7 ELECTRICAL CIRCUIT CHECK (WHITE-RED) FOR A BREAK |

|

|

1 Disconnect the C809 instrument panel. |

|

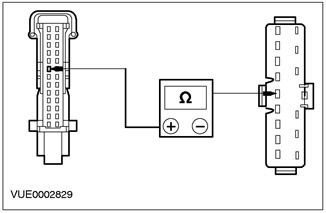

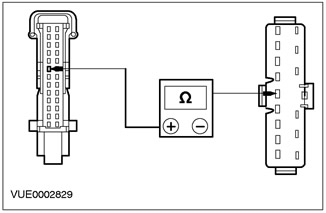

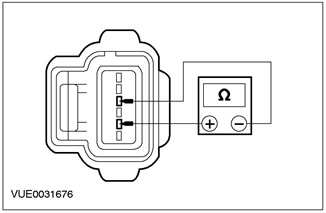

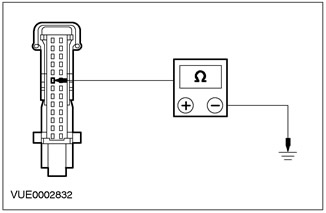

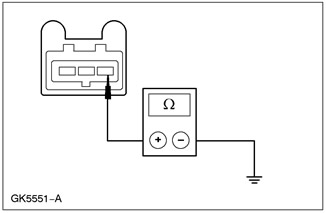

2 Measure the resistance between pin 8 C809 of the instrument panel, circuit 8-GA7 (white-red), from the wiring side, and «weight». |

|

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

A7: RECOVERING STORED DTCs |

|

|

1 Connect the C732 fuel pump module. |

|

|

2 Activate instrument cluster self-test number 6, list of stored DTCs. |

|

|

• Are any DTCs stored in memory? |

|

|

→ Yes |

|

|

REFER to instrument panel DTC list. |

|

|

→ No |

|

|

Install a new fuel pump module. See Section 310-01 for more information. CHECK the system is working properly. |

|

|

A8: INSPECT CIRCUIT 8-GA7 (WHITE-RED) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Disconnect C61/C63. |

|

|

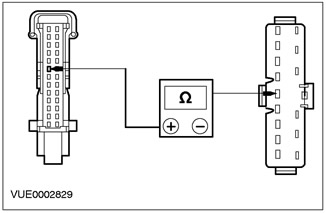

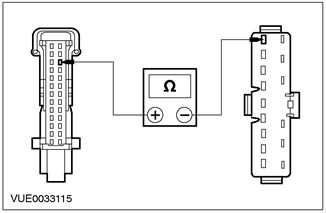

4 Measure the resistance between pin 8 C809 of the instrument panel, circuit 8-GA7 (white-red), from the wiring side, and pin 11 C63, electrical circuit 8-GA7 (white-red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A9 |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

|

A9: 8-GA7 ELECTRICAL CIRCUIT CHECK (WHITE-RED) FOR A BREAK |

|

|

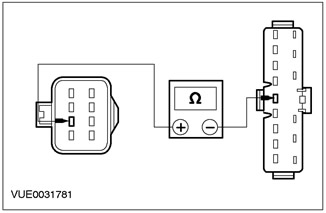

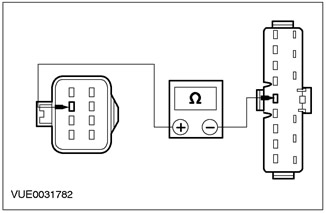

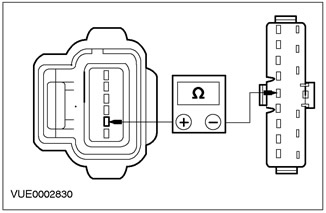

1 Measure the resistance between pin 2 C21 of the adaptive fuel module circuit 8-GA7 (white-red), from the wiring side, and pin 21 C61, electrical circuit 8-GA7 (white-red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A10 |

|

|

→ No |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

A10: 9-GA7 ELECTRICAL CIRCUIT CHECK (BROWN-RED) FOR A BREAK |

|

|

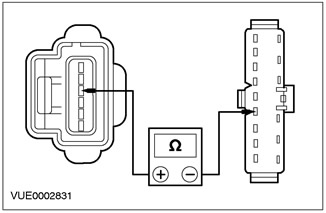

1 Measure the resistance between pin 3 C21 of the adaptive fuel module circuit 9-GA7 (brown red), from the wiring side, and pin 20 C61, electrical circuit 9-GA7 (brown red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A11 |

|

|

→ No |

|

|

REPAIR Circuit 9-GA7 (brown red). CHECK the system is working properly. |

|

|

A11: 9-GA7 ELECTRICAL CIRCUIT CHECK (BROWN-RED) FOR A BREAK |

|

|

1 Measure the resistance between pin 15 C809 of the instrument panel, circuit 9-GA7 (brown red), from the wiring side, and pin 10 C63, electrical circuit 9-GA7 (brown red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A12 |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

|

A12: FUEL TANK SENSOR OPEN CHECK |

|

|

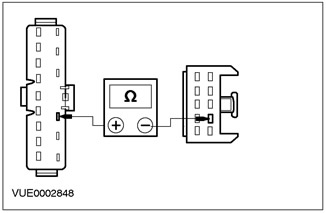

1 Disconnect the C732 fuel pump module. |

|

|

2 Measure the resistance between C372 pin 2 of the fuel pump module circuit 8-GA7 (white-red), wiring side, and pin 4 C372 of the fuel pump module, circuit 9-GA7 (brown red), from the side of the electrical wiring. |

|

• Is the resistance greater than 150 ohms? |

|

|

→ Yes |

|

|

INSTALL a new fuel pump module. See Section 310-01 for more information. CHECK the system is working properly. |

|

|

→ No |

|

|

INSTALL a new adaptive fuel module. Check the correct operation of the system. |

|

|

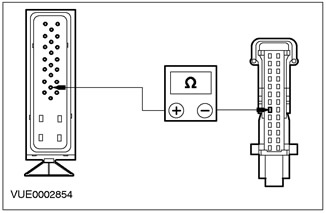

A13: 8-GA7 ELECTRICAL CIRCUIT CHECK (WHITE-RED) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Disconnect C61/C63. |

|

|

4 Measure the resistance between pin 8 C809 of the instrument panel, circuit 8-GA7 (white-red), from the wiring side, and pin 11 C63, electrical circuit 8-GA7 (white-red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A14 |

|

|

→ No |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

A14: 8-GA7 ELECTRICAL CIRCUIT CHECK (WHITE-RED) FOR A BREAK |

|

|

1 Disconnect the C732 fuel pump module. |

|

|

2 Measure the resistance between C732 pin 2 of the fuel pump module circuit 8-GA7 (white-red), from the wiring side, and pin 21 C61, electrical circuit 8-GA7 (white-red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A15 |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

|

A15: 9-GA7 ELECTRICAL CIRCUIT CHECK (BROWN-RED) FOR A BREAK |

|

|

1 Measure the resistance between C732 pin 4 of the fuel pump module circuit 9-GA7 (brown red), from the wiring side, and pin 20 C61, electrical circuit 9-GA7 (brown red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to A16 |

|

|

→ No |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

A16: 9-GA7 ELECTRICAL CIRCUIT CHECK (BROWN-RED) FOR A BREAK |

|

|

1 Measure the resistance between pin 15 C809 of the instrument panel, circuit 9-GA7 (brown red), from the wiring side, and pin 10 C63, electrical circuit 9-GA7 (brown red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new fuel pump module. See Section 310-01 for more information. CHECK the system is working properly. |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

|

A17: CHECK FOR SHORT CIRCUIT ON «MASS» FUEL TANK SENSOR ELECTRICAL CIRCUIT |

|

|

1 Disconnect the C732 fuel pump module. |

|

|

• Does the fuel input value change to F255? |

|

|

→ Yes |

|

|

INSTALL a new fuel pump module. See Section 310-01 for more information. CHECK the system is working properly. |

|

|

→ No |

|

|

Go to A18 |

|

|

A18: 8-GA7 ELECTRICAL CIRCUIT CHECK (WHITE-RED) FOR A BREAK |

|

|

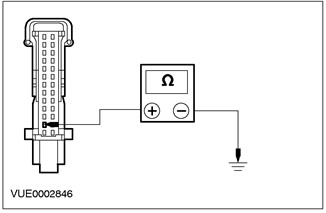

1 Disconnect the instrument panel C809. |

|

|

2 Measure the resistance between pin 8 C809 of the instrument panel, circuit 8-GA7 (white-red), from the wiring side, and «weight». |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

PINPOINT TEST B: SPEEDOMETER DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

B1: CHECKING THE FUNCTION OF THE SPEEDOMETER |

|

|

1 Activate instrument cluster self-test number one, pointer sweep. |

|

|

• Is the speedometer needle sweeping? |

|

|

→ Yes |

|

|

Navigate to B2 |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

B2: RECOVERY OF ANY STORED DTCs |

|

|

1 Activate instrument panel self-test number 6, list of stored DTCs. |

|

|

• Are any DTCs stored in memory? |

|

|

→ Yes |

|

|

REFER to instrument panel DTC list. |

|

|

→ No |

|

|

Go to B3 |

|

|

B3: VEHICLE SPEED SENSOR OUTPUT TEST (VSS) |

|

|

1 Activate instrument cluster self-test number 7 (miles per hour) or number 8 (km/h), vehicle speed input. - Vehicle speed input monitoring requires the vehicle to be moving during this test. |

|

|

• Does the speed signal change with speed? |

|

|

→ Yes |

|

|

Go to N1 |

|

|

→ No |

|

|

REFER to WDS for PCM and SCP channel diagnostics. Additional DIAGNOSIS of the VSS sensor is required. See Section 303-14 for more information. |

|

PINPOINT TEST C: INCORRECT TEMPERATURE GAUGE

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

C1: CHECKING THE FUNCTION OF THE TEMPERATURE GAUGE |

|

|

1 Activate instrument cluster self-test number one, pointer sweep. |

|

|

• Does the temperature gauge needle go through full sweep? |

|

|

→ Yes |

|

|

Go to C2 |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

C2: RECOVERY OF ANY STORED DTCs |

|

|

1 Activate instrument cluster self-test number 6, retrieve stored DTCs. |

|

|

• Are there any DTCs stored in the memory? |

|

|

→ Yes |

|

|

REFER to instrument panel DTC list. |

|

|

→ No |

|

|

Go to C3 |

|

|

C3: CYLINDER HEAD TEMPERATURE SENSOR CHECK (CHT) |

|

|

1 Activate instrument cluster self-test number 11, engine temperature input. - Check the input signal when the engine is cold and when the engine is warm. |

|

|

• Is there an input signal from the engine temperature sensor? |

|

|

→ Yes |

|

|

Go to N1 |

|

|

→ No |

|

|

Refer to WDS for PCM and SCP channel diagnostics. Additional DIAGNOSIS of the temperature sensor is required. |

|

PINPOINT TEST D: TACHO DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

D1: TACHOMETER FUNCTION CHECK |

|

|

1 Activate instrument cluster self-test number one, pointer sweep. |

|

|

• Does the tachometer needle go through full sweep? |

|

|

→ Yes |

|

|

Go to D2 |

|

|

→ No |

|

|

INSTALL a new instrument panel. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

D2: RECOVERY OF ANY STORED DTCs |

|

|

1 Activate instrument panel self-test number 6, list of stored DTCs. |

|

|

• Are there any DTCs stored in the memory? |

|

|

→ Yes |

|

|

Refer to the list of instrument panel DTCs. |

|

|

→ No |

|

|

Go to D3 |

|

|

D3: TACH INPUT CHECK |

|

|

1 Activate instrument cluster self-test number 9, tachometer input test (RPM). |

|

|

• Is there an RPM input present? |

|

|

→ Yes |

|

|

Go to N1 |

|

|

→ No |

|

|

Refer to WDS for PCM and SCP channel diagnostics. Additional tachometer DIAGNOSIS required |

|

PINPOINT TEST E: HIGH BEAM INDICATOR LAMP DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

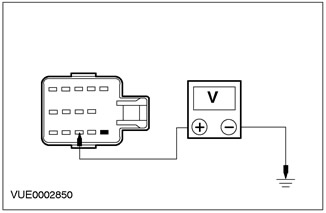

E1: 15S-LE11 ELECTRICAL VOLTAGE TEST (GREEN-WHITE) |

|

|

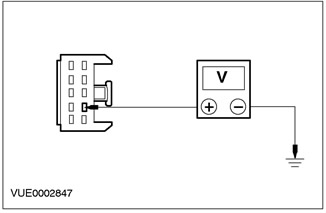

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Drive the ON position. |

|

|

4 Turn the headlight switch to «DOWN LIGHT». |

|

|

5 Set the multifunction switch to «HIGH LIGHT». |

|

|

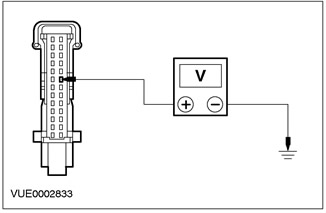

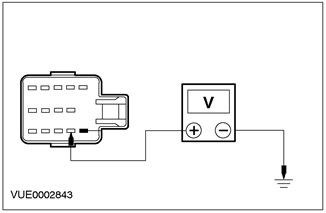

6 Measure voltage between pin 21 C809 of instrument panel, circuit 15S-LE11 (green-white), from the wiring side, and «weight». |

|

• Is the voltage greater than 10 V? |

|

|

→ Yes |

|

|

Go to E2 |

|

|

→ No |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

|

E2: 91-GG14 ELECTRICAL CIRCUIT CHECK (BLACK AND ORANGE) FOR A SHORT TO THE HIGH BEAM PILOT |

|

|

1 Measure the resistance between pin 2 C809 of the instrument panel, circuit 91-GG14 (black-orange), from the wiring side, and «weight». |

|

• Is the resistance always less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new high beam indicator bulb. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

PINPOINT TEST F: DOOR LOCK WARNING LIGHT DOES NOT WORK / IS ON PERMANENTLY

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

F1: ELECTRICAL CIRCUIT CHECK 31S-AA17 (BLACK-BLUE) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect C15 CJB. |

|

|

3 Disconnect the C809 instrument panel. |

|

|

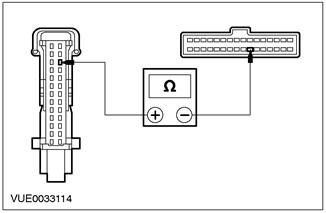

4 Measure the resistance between pin 24 of instrument cluster connector C809, circuit 31S-AA17 (black and blue), and pin 15 of C15 CJB connector, circuit 31S-AA17 (black and blue). |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to F2 |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

|

F2: CHECK CJB FOR A BREAK |

|

|

1 Connect C15 CJB. |

|

|

2 Disconnect the C1000 CTM. |

|

|

3 Measure the resistance between pin 24 of instrument cluster connector C809, circuit 31S-AA17 (black and blue), and pin 23 of the C1000 CTM connector, on the CJB side. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

The fault is in the door lock. See Section 501-14 for more information. |

|

|

→ No |

|

|

Install a new CJB. Check the correct operation of the system. |

|

PINPOINT TEST G: OIL LIGHT DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

G1: CHECKING THE OPERATION OF THE OIL LIGHT |

|

|

1 Drive the ON position. |

|

|

• Is the low fuel warning light on? |

|

|

→ Yes |

|

|

CHECK the condition of the bulb. For more information, refer to Instrument panel available in this section. If the bulb is OK, INSTALL a new instrument cluster. Check the correct operation of the system. |

|

|

→ No |

|

|

Go to G2 |

|

|

G2: ELECTRICAL CIRCUIT CHECK 31S-GC20 (BLACK AND ORANGE) FOR A BREAK |

|

|

1 Detach C953 (1.4/1.6) or C954 (1.8/2.0) oil pressure switch. |

|

|

2 Drive the ON position. |

|

|

3 Connect connector C953 (1.4L/1.6L) or C954 (1.8L/2.0L) With «weight». |

|

|

• Is the oil pressure warning light on? |

|

|

→ Yes |

|

|

INSTALL a new oil pressure switch. Check the correct operation of the system. |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

PINPOINT TEST H: BRAKE WARNING LIGHT DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

H1: CHECKING THE OPERATION OF THE BRAKE LAMP |

|

|

1 Activate instrument cluster self-test number 3, warning lights on. |

|

|

• Is the brake system warning light on? |

|

|

→ Yes |

|

|

Go to H2 |

|

|

→ No |

|

|

INSTALL a new bulb. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

H2: 31S-GC6 BRAKE FLUID LEVEL SWITCH CIRCUIT CHECK (BLACK YELLOW) |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C810 brake fluid level switch. |

|

|

3 Drive the ON position. |

|

|

4 Make sure the parking brake is applied. |

|

|

5 Connect the jumper wire between C810 brake fluid level switch pin 2, circuit 31S-GC6 (black and yellow), on the wiring side, and pin 3 C810 of the electrical circuit 31S-GE44 (black and red), from the side of the electrical wiring. |

|

• Is the brake system warning light on? |

|

|

→ Yes |

|

|

INSTALL a new brake fluid level switch. CHECK the system is working properly. |

|

|

→ No |

|

|

Remove the connecting wire. Go to H3 |

|

|

H3: 31S-GE44 ELECTRICAL CIRCUIT CHECK (BLACK-RED) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Measure the resistance between C810 brake fluid level switch pin 3, circuit 31S-GE44 (black and red), And «weight». |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

REPAIR circuit 31S-GC6 (black and yellow). CHECK the system is working properly. |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

PINPOINT TEST I: LOW FUEL LIGHT DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

I1: PILOT LAMP CHECK |

|

|

NOTE: The Low Fuel Warning Light will only illuminate if allowed by the module configuration. |

|

|

1 Activate instrument cluster self-test number 3, warning lights on. |

|

|

• Is the low fuel warning light on? |

|

|

→ Yes |

|

|

Go to I2 |

|

|

→ No |

|

|

CHECK the condition of the bulb. For more information, refer to Instrument panel available in this section. If the bulb is OK, INSTALL a new instrument cluster. Check the correct operation of the system. |

|

|

I2: CHECKING THE PRESENCE OF A ROUTE COMPUTER |

|

|

1 |

|

|

• Is the car equipped with a trip computer? |

|

|

→ Yes |

|

|

Vehicles equipped with a trip computer do not use the low fuel warning light. Check the correct operation of the system. |

|

|

→ No |

|

|

Go to I3 |

|

|

I3: CONFIGURATION CHECK OF INSTRUMENT PANEL |

|

|

1 |

|

|

• Is the instrument panel configured correctly? |

|

|

→ Yes |

|

|

Go to A1 Go to PINPOINT TEST A |

|

|

→ No |

|

|

To configure the module, REFER to the option «Programmable Module Installer» wds. Check the correct operation of the system. |

|

PINPOINT TEST J: TURN SIGNAL LIGHT DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

J1: LEFT TURN SIGNAL FUNCTION TEST |

|

|

1 Drive the ON position. |

|

|

2 Set the turn signal switch to the left turn signal position. |

|

|

• Does the indicator lamp for the left turn signal on the instrument panel light up? |

|

|

→ Yes |

|

|

Go to J10 |

|

|

→ No |

|

|

Go to J2 |

|

|

J2: LEFT TURN SIGNAL LAMP TEST |

|

|

1 Check the operation of the left turn signal lamp. |

|

|

• Does the left turn signal work? |

|

|

→ Yes |

|

|

Go to J3 |

|

|

→ No |

|

|

See Section 417-01 for more information. |

|

|

J3: CHECK FOR VOLTAGE ON HAZARD LIGHT BUTTON |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C458 hazard warning light button. |

|

|

3 Drive the START position. |

|

|

4 Measure the voltage between pin 3 C458 of the hazard warning light button, circuit 15S-LG1 (green-yellow) And «weight». |

|

• Is there a voltage pulse present? |

|

|

→ Yes |

|

|

Go to J4 |

|

|

→ No |

|

|

Go to J7 |

|

|

J4: INSTRUMENT PANEL VOLTAGE CHECK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Drive the ON position. |

|

|

4 Measure voltage between pin 23 C809 of instrument panel, circuit 49S-LG15 (black and blue), And «weight». |

|

• Is the voltage greater than 10 V? |

|

|

→ Yes |

|

|

Go to J6 |

|

|

→ No |

|

|

Go to J5 |

|

|

J5: 49-LG15 ELECTRICAL CIRCUIT CHECK (BLACK-BLUE) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C458 hazard warning light button. |

|

|

3 Measure the resistance between pin 23 C809 of instrument panel, circuit 49-LG15 (black and blue), on the wiring side, and pin 12 of connector C458 of the hazard warning light button. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new hazard warning light switch. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

|

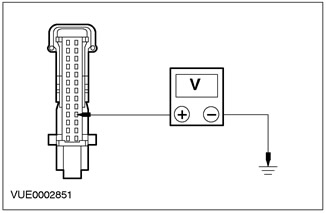

J6: INSTRUMENT PANEL GROUND CHECK |

|

|

1 Disconnect the C809 instrument panel. |

|

|

2 Measure the resistance between pin 2 of instrument panel connector C809, circuit 91-GG14 (black and blue), And «weight». |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new indicator light bulb. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

|

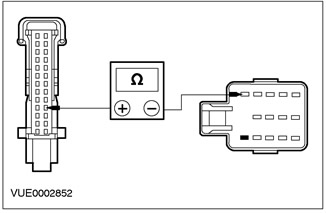

J7: 15S-LG1 ELECTRICAL CIRCUIT CHECK (GREEN YELLOW) FOR A BREAK |

|

|

1 Using a digital multimeter, measure the resistance between pin 3 of connector C458 of the hazard warning light button, circuit 15S-LG1 (green-yellow), and pin 1 of connector C459 of the multifunction switch. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to J8 |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

|

J8: CENTRAL JUNCTION BOX VOLTAGE CHECK (CJB) |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C459 multifunction switch. |

|

|

3 Drive the ON position. |

|

|

4Measure the voltage between pin 2 of connector C459 of multifunction switch circuit 15-LG27 (green-black), And «weight». |

|

• Is there a voltage pulse present? |

|

|

→ Yes |

|

|

INSTALL a new multifunction switch. Check the correct operation of the system. |

|

|

→ No |

|

|

Go to J9 |

|

|

J9: CENTRAL JUNCTION BOX CHECK (CJB) FOR A BREAK |

|

|

1 Disconnect C15 CJB. |

|

|

2 Measure the resistance between pin 3 of connector C15 CJB, circuit 15-LG27 (green-black), and pin 2 of connector C459 of the multifunction switch. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

REPAIR or INSTALL a new CJB. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

|

J10: RIGHT TURN SIGNAL FUNCTION TEST |

|

|

1 Set the turn signal switch to the right turn signal. |

|

|

• Is the right turn signal indicator light on? |

|

|

→ Yes |

|

|

The car is correct. |

|

|

→ No |

|

|

Go to J11 |

|

|

J11: RIGHT TURN SIGNAL LAMP TEST |

|

|

1 Check the operation of the right turn signal lamp. |

|

|

• Is the right turn signal light on? |

|

|

→ Yes |

|

|

Go to J12 |

|

|

→ No |

|

|

See Section 417-01 for more information. |

|

|

J12: VOLTAGE CHECK ON HAZARD LIGHT BUTTON |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C458 hazard warning light button. |

|

|

3 Drive the ON position. |

|

|

4 Measure the voltage between pin 6 C458 of the hazard warning light button, circuit 15S-LG2 (green-blue), And «weight». |

|

• Is the voltage greater than 10 V? |

|

|

→ Yes |

|

|

Go to J13 |

|

|

→ No |

|

|

Go to J15 |

|

|

J13: INSTRUMENT PANEL VOLTAGE CHECK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Drive the ON position. |

|

|

4 Measure the voltage between pin 17 of instrument cluster connector C809, circuit 49S-LG22 (yellow-blue), And «weight». |

|

• Is the voltage greater than 10 V? |

|

|

→ Yes |

|

|

Go to J6 |

|

|

→ No |

|

|

Go to J14 |

|

|

J14: 49S-LG22 ELECTRICAL CIRCUIT CHECK (YELLOW-BLUE) AND 49S-LG4 FOR A BREAK |

|

|

1 Measure the resistance between pin 17 of instrument cluster connector C809, circuit 49S-LG22 (yellow-blue), and pin 14 of connector C458 of the hazard warning light button, circuit 49S-LG4 (red-blue). |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new hazard warning light button. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. Check the correct operation of the system. |

|

|

J15: 15S-LG2 ELECTRICAL CIRCUIT CHECK (GREEN-BLUE) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C458 hazard warning light button. |

|

|

3 Measure the resistance between pin 6 of connector C458 of the hazard warning light button, circuit 15S-LG2 (green-blue), and pin 3 of connector C459 of the multifunction switch. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

Go to J8 |

|

|

→ No |

|

|

Repair the electrical circuit. Check the correct operation of the system. |

|

PINPOINT TEST K: CHARGING INDICATOR LIGHT ON

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

K1: CHARGING LAMP FUNCTIONAL CHECK |

|

|

1 Activate instrument cluster self-test number 3, warning lights on. |

|

|

• Is the charging system indicator light on? |

|

|

→ Yes |

|

|

The charging system is faulty. See Section 414-02 for more information. |

|

|

→ No |

|

|

INSTALL a new bulb. For more information, refer to Instrument panel available in this section. |

|

PINPOINT TEST L: EMISSION CONTROL WARNING LIGHT (MIL) NOT FUNCTIONAL / PERMANENTLY ON

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

L1: EMISSION CONTROL LAMP CONTROL |

|

|

1 Drive the ON position. |

|

|

2 check the emission control system malfunction indicator lamp (MIL). |

|

|

• Is the MIL indicator light on? |

|

|

→ Yes |

|

|

Go to L3 |

|

|

→ No |

|

|

Go to L2 |

|

|

L2: EMISSION CONTROL LAMP FUNCTIONAL CHECK |

|

|

1 Activate instrument cluster self-test number 3, warning lights on. |

|

|

• Is the MIL indicator light on? |

|

|

→ Yes |

|

|

Go to L3 |

|

|

→ No |

|

|

INSTALL a new bulb. For more information, refer to Instrument panel available in this section. |

|

|

L3: EMISSION CONTROL LAMP CONTINUATION CHECK |

|

|

1 Cycle the ignition switch leaving the ignition switch in position II. |

|

|

• Does the MIL indicator go out within 10 seconds? |

|

|

→ Yes |

|

|

The system is correct. |

|

|

→ No |

|

|

REFER to WDS. |

|

PINPOINT TEST M: ABS WARNING LIGHT DOES NOT WORK

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

M1: SYSTEM OPERATION CHECK |

|

|

1 Drive the ON position. |

|

|

2 Check the ABS warning light. |

|

|

• Is the ABS warning light on? |

|

|

→ Yes |

|

|

If the control lamp lights up for three seconds, the car is serviceable. If the warning light stays on, diagnose the ABS system using WDS. |

|

|

→ No |

|

|

Navigate to M2 |

|

|

M2: CHECK ABS LAMP FUNCTION |

|

|

1 Activate instrument cluster self-test number 3, warning lights on. |

|

|

• Is the ABS warning light on? |

|

|

→ Yes |

|

|

Go to M3 |

|

|

→ No |

|

|

INSTALL a new bulb. For more information, refer to Instrument panel available in this section. CHECK the system is working properly. |

|

|

M3: INSTRUMENT PANEL CONFIGURATION CHECK |

|

|

1 |

|

|

• Is the instrument panel configured correctly? |

|

|

→ Yes |

|

|

Go to M4 |

|

|

→ No |

|

|

To configure the module, REFER to the option «Programmable Module Installer» wds. CHECK the system is working properly. |

|

|

M4: 31S-CF28 ELECTRICAL CIRCUIT CHECK (BLACK-RED) FOR A BREAK |

|

|

1 Enter the OFF position. |

|

|

2 Disconnect the C809 instrument panel. |

|

|

3 Disconnect the C385 ABS control module. |

|

|

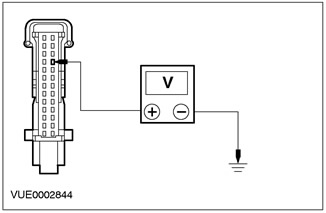

4 Measure the resistance between pin 15 of connector C385 of the ABS control module, circuit 31S-CF28 (black and red), wiring side, and pin 18 of instrument panel connector C809, circuit 31S-CF28 (black and red), from the side of the electrical wiring. |

|

• Is the resistance less than 5 ohms? |

|

|

→ Yes |

|

|

INSTALL a new instrument panel. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the electrical circuit. CHECK the system is working properly. |

|

PINPOINT TEST N: AUXILIARY INPUT ERROR

|

STATES |

DETAILS/RESULTS/ACTIONS |

|

N1: AUXILIARY INPUT CHECK - IGNITION POSITION II |

|

|

1 Drive the ON position. |

|

|

2 Activate instrument panel self-test number 16, starting status. |

|

|

• Is the display showing Cr-L? |

|

|

→ Yes |

|

|

Auxiliary channel error. Go to N2 |

|

|

→ No |

|

|

Go to N3 |

|

|

N2: FUSE CHECK 59 (7.5 A) |

|

|

1 Check fuse 59 (7.5 A). |

|

|

• Is the fuse good? |

|

|

→ Yes |

|

|

Go to N3 |

|

|

→ No |

|

|

INSTALL new fuse 59 (7.5 A). Check the correct operation of the system. |

|

|

N3: AUXILIARY INPUT CHECK - IGNITION POSITION III |

|

|

1 Momentarily turn the ignition to position 3 (cranking position of the crankshaft) and check for any input signal changes in self-test 16. |

|

|

• Does the input signal change to Cr-L? |

|

|

→ Yes |

|

|

INSTALL a new instrument panel. CHECK the system is working properly. |

|

|

→ No |

|

|

REPAIR the auxiliary circuit circuit. CHECK the system is working properly. |

|

Visitor comments