Introduction

The workshop manual is written in a new format to meet the needs of Ford technicians around the world. The ultimate goal is to use common formats and have similar content in each of the Workshop Manuals used around the world.

This manual contains a general description of the relevant maintenance and repair work on the vehicle using proven, efficient equipment. Following the described procedures will guarantee the quality of the work performed.

Spare parts for replacement

Ford and Motorcraft replacement parts are manufactured to the same standards as original factory installed parts. For this reason, we recommend that you use only genuine Ford or Motorcraft replacement parts for service or repair.

Special tools

Special tool table (ov), which precedes each procedure, shows all the special tools required to complete the repair. Where possible, illustrations are provided to help identify the required special tool. Special tools can be ordered from Loewener OTC GmbH, Rotunda Equipment or its agents/distributors.

| Europe | North America |

| V Loewener OTC GmbH | Rotunda Equipment |

| Industriestrasse 67 | PO Box 1450 |

| D 40764 Langenfeld | Kenosha W1 53141-1450 |

| Germany | Phone 1-800-ROTUNDA |

| Tel: + 49 (0) 2173 928-0 | Fax: +1-800-762-6181 () |

| Fax: + 49 (0) 2173 928-199 | WWW.FORDROTUNDA.COM |

Important Precautions

The use of proper maintenance practices and the correct execution of repair procedures is important both for the safe, reliable operation of the vehicle itself and for the personal safety of the technician performing the particular job. This manual cannot fully cover all options and provide recommendations and cautions for each of them. Therefore, anyone who intends to deviate from the instructions prescribed by this manual must decide for himself what he is willing to sacrifice: personal safety or the car itself. And already proceeding from this, he must choose the necessary methods, tools and spare parts.

Warnings, Cautions, and Notes Used in This Manual

WARNING: Warnings indicate that personal injury may result if a procedure is not followed correctly.

CAUTION: Cautions indicate that damage to the vehicle or the equipment being used may result if the procedure is not followed correctly.

NOTE: The purpose of the note is to provide additional important information required for a complete and satisfactory repair.

As you read this manual, you will come across WARNINGS, CAUTIONS, and NOTES.

If a warning, caution or note refers to a series of items, it is given at the beginning of the sequence. If it refers to only one item, it precedes that item (located after the item number).

How to use this manual

The workshop manual provides information on maintenance and repair procedures.

This guide is divided into groups and sections. Sections dedicated to special systems are collected together in the appropriate group. The group is dedicated to a specific part of the car. This manual is divided into five groups: General, Chassis, Powertrain, Electrical, Body &Paint. The group number is the first digit of the section number.

The pages at the beginning of this manual list all available sections. Each section has a list that reveals the contents of the chapters "General specifications", "Description and principle of operation" And "Service adjustments and checks".

If the elements need to be removed or disassembled in a certain sequence, they will be indicated in the illustration with the corresponding numbers and the accompanying text will be numbered accordingly (refer to ch. «Examples»).

All references to the left or right side related to the car are determined by the position of the driver sitting in the seat and looking forward.

All references to the left or right side related to the engine are determined by the position of the flywheel facing in the direction of the front camshaft pulley.

Instructions on how to use WDS, FDS2000 or next generation STAR diagnostic equipment will be provided as needed (NGS).

Inspection and verification

Visual Inspection Tables, Troubleshooting Tables and Other Information Tables (such as tables containing diagnostic programs), additional test procedures with technical specifications, or directing the user to a specific test procedure.

Symptom table

The Troubleshooting Symptom Table indicates the symptoms of the malfunction, the causes of the malfunction, and the necessary actions to find the cause.

Pinpoint tests

When diagnosing electrical systems, Pinpoint tests are used to determine the source of a problem. Testing is performed in a logical, step-by-step sequence. Pinpoint tests are divided into two columns: "STATES" And "DETAILS/RESULTS/ACTIONS".

Column «STATES» used exclusively for graphical information and pictograms (with or without captions), and the column «DETAILS/ RESULTS/ ACTIONS» directs the technician to another inspection point or contains a description of special corrective actions.

The numbers in the boxes indicate the sequence in which the described actions should be performed.

Item checks

Element validation is performed when an element is being validated in complex/composite pinpoint tests, or if the procedure is too complex to fit within a single pinpoint test page.

Graphic images

The graphics illustrate the measurement or test to be performed within a given test item.

For voltmeters and ohmmeters, the image of the tester is used.

If one graphic refers to several measurements, first the test leads are drawn as a solid line, and then, starting from the point where the wires are separated to illustrate individual measurements, they are (wires) are shown with a broken line.

The splitter box/testers are represented by a test pin in a double circle. Test pins are marked with a pin number.

Examples

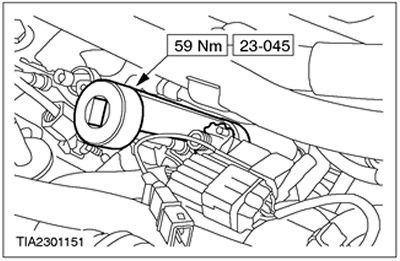

Special tools and tightening torques Any need to use a special tool will be reflected in a drawing showing how to use the tool and the tool number. Torque values will be given at the appropriate place in the procedure description.

Visitor comments