Special tool

| Ultraviolet Light Diagnostic Kit (12V) 12-Volt Master UV Diagnostic Inspection Kit 164-R0756 or equivalent |

CAUTION: Do not attempt to stop fluid leaks by tightening too much. This may damage the crankcase threads.

Check the hydraulic fluid fill line on the transaxle case. If a leak is found, install a new plug.

Check piping and fittings between transaxle case and cooler for looseness, wear or damage. If leakage cannot be stopped by tightening the fluid line nut, install new elements.

If the leak persists, install a new refrigerant line connector and torque to specification. The same procedure should be followed for fluid leaks between the coolant and coolant line connectors as described in this section. See Section 307-02 for more information.

The cooler can be checked further for leaks. See Section 307-02 for more information.

If a leak is found in the selector lever, install a new seal.

If a leak is found in the transaxle wiring connector area, install a new O-ring.

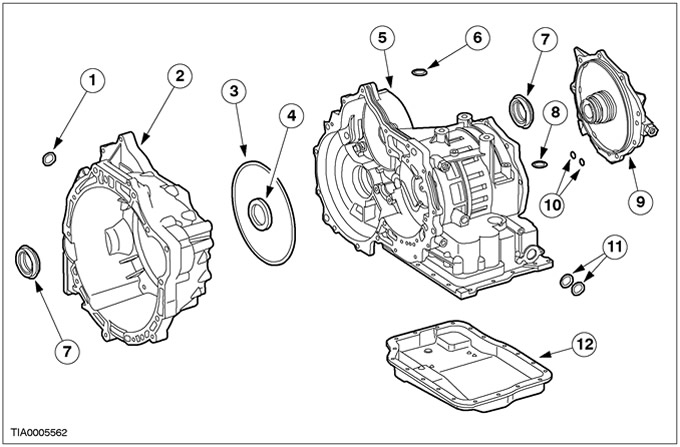

To prevent external leakage of transmission fluid in the gearbox in the block with the drive axle, there are the following elements:

- sealant

- lip type seals

- o-rings of circular cross-section

- O-rings

- sealing sleeves (stockings)

- thread sealant

- working fluid crankcase

Outer seal

| Pos. | Spare Part No | Name |

| 1 | — | O-ring for secondary shaft speed sensor |

| 2 | — | Torque converter housing (sealant at the junction with the crankcase) |

| 3 | — | Fluid Pump Seal |

| 4 | — | Fluid Pump Seal |

| 5 | — | Carter (sealant at the junction with the torque converter housing) |

| 6 | — | O-ring for turbine speed sensor |

| 7 | — | Differential seal assy |

| 8 | — | O-Ring - Bulkhead Wiring Connector |

| 9 | — | End cap assembly (sealant at the junction with the map-rum) |

| 10 | — | Crankcase cover seal (2 pcs., end cap to crankcase) |

| 11 | — | Hand shaft seal (2 pcs.) |

| 12 | — | oil sump (sealant at the junction with the crankcase) |

Transmission fluid leak in the torque converter area

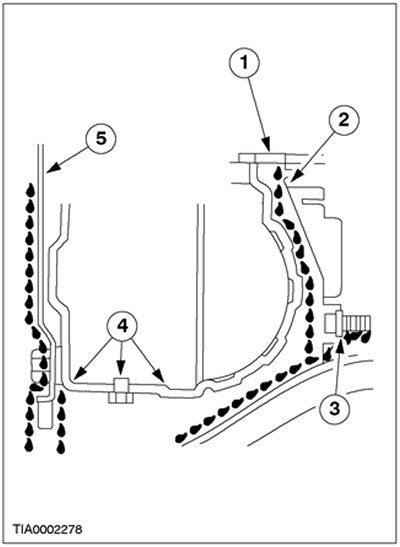

When diagnosing and repairing transmission fluid leaks in the pump mount, gearbox, and torque converter area, use the following procedures to determine the true source of the leak. A leak between the transaxle and the engine, manifested as transmission fluid around the torque converter housing, can have several causes. In many cases, it is possible to pinpoint the source of a leak by performing a thorough inspection without removing the transaxle from the vehicle. The paths that the transmission fluid travels when it reaches the bottom of the torque converter housing are shown in the figure. The next five steps correspond to the numbers in the illustration.

1. Fluid passing through the pump lip seal will tend to flow along the impeller hub and then to the back of the impeller housing. Also, in the event of a general seal failure, fluid that has passed through that seal will only accumulate on the inside of the torque converter housing, near the outside diameter of the housing. Fluid from the vent can pass along the hub of the impeller and on to the back surface of the impeller housing. Fluid that has passed through the weld on the torque converter hub will run along the inside of the torque converter housing.

2. Fluid passed through the oil pump seal mating surface (by outside diameter) and the pump housing, will follow the same path as the leak through the inside diameter of the oil pump seal. Fluid that has passed through the weld on the torque converter hub will run along the inside of the torque converter housing.

3. Fluid that passes through the pump to crankcase screw or through the pump gasket will only accumulate on the inside of the torque converter housing. Fluid will not accumulate on the back of the torque converter.

4. Leakage of working fluid from the drain plug of the transformer, (depending on the model) A transformer seal weld or a stud weld that connects the transformer to the flex plate will appear on the outside diameter of the torque converter on the back of the flex plate and in the transformer housing next to the flex plate. Fluid leaks from the torque converter will leave an annular fluid trail around the inside surface of the torque converter housing.

NOTE: A white sanitary napkin can help determine the color (red corresponds to the working fluid of the gearbox in the block with the drive axle) and the source of leakage of the working fluid.

5. Engine oil leaks are sometimes mistaken for transmission pump gasket leaks in the drive axle assembly. To determine if the engine oil is causing the problem, the following areas of possible leakage should also be checked.

- a Leaks at the cylinder head cover gasket can allow oil to overflow from the torque converter housing or seep between the torque converter housing and cylinder block, causing oil to pool in the housing or on the bottom of the torque converter housing.

- b Leaks at the oil gallery plug allow oil to flow over the back of the cylinder block to the bottom of the torque converter housing.

- c Leakage at the crankshaft rear oil seal is leaking back to the flex plate and then inside the torque converter housing.

Check for leaks

1. Factory-filled transmission fluid is dyed red to help identify if the leak is from the engine or transaxle. The red color should help pinpoint the exact location of the leak.

2. Wipe off all traces of fluid from the top and bottom of the converter housing, crankcase, rear of the engine, and oil sump. Clean the converter area by flushing it with a suitable non-flammable solvent. Then dry it with compressed air.

3. Wipe the converter housing and the front of the flexible plate. The torque converter housing can be washed with a cleaning solvent. Blow dry all washed areas with compressed air.

4. Start the engine and let it run until the transaxle has reached its normal operating temperature. Watch the back of the cylinder block and the top surface of the torque converter housing for fluid leaks. Raise the car on a lift (refer to Section 100-02) and start the engine by running it at high idle and then at normal idle, shifting the transmission to D and R from time to time to pressurize the transaxle in the transaxle block. Watch the front of the flexible plate, the back of the cylinder block (as much as possible) and the inner surface of the torque converter housing and the front of the crankcase. Run the engine until a fluid leak occurs and the likely source of the leak can be identified.

Checking for leaks under black light

Soluble aniline or fluorescent dyes, pre-mixed in a proportion of 2.5 ml (1/2 teaspoon) powder dye for 0.24 l (1/2 pint) transmission fluid for an automatic transmission in a block with a drive axle, are useful in finding sources of leakage of the working fluid. Such dyes can be used to determine whether the leak is engine oil or transmission fluid. Ultraviolet light can be used to determine the presence of a fluorescent dye solution.

Transmission fluid cooler

CAUTION: Cleaning and backflushing is required every time the transaxle is dismantled to install new components (countercurrent) transmission fluid cooler lines and install a new transmission fluid cooler.

NOTE: Cleaning and backwashing (countercurrent) The transmission fluid cooling systems, together with the normal cleaning and inspection procedures performed as prescribed in this section during disassembly and reassembly, will prevent re-entry of contamination into the transaxle transaxle. There is also no need for refurbishment.

If there is internal wear or damage in the transaxle transaxle, metal particles, clutch disc material or band brake material may have entered the torque converter and transmission fluid cooler. This contamination is the main reason for the repeated occurrence of faults in the transaxle unit. All foreign matter/contamination must be removed from the system before the transaxle is put into service.

Visitor comments