Special tool

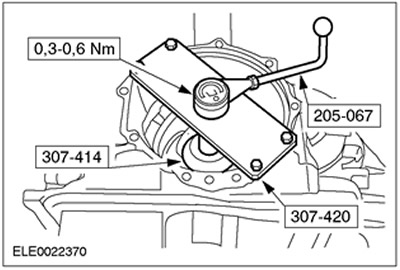

| Device for measuring preload 205-067 (15-041) |

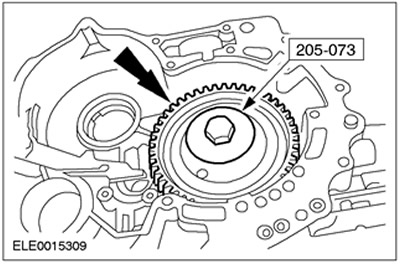

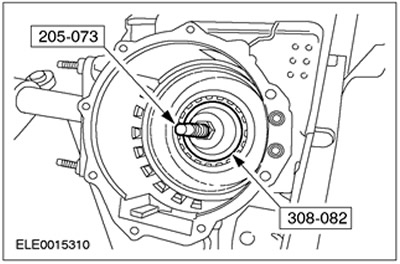

| Differential bearing inner ring installer 205-073 (15-034) |

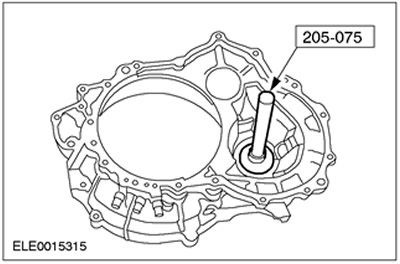

| Rear wheel hub oil seal installer 205-075 (15-036) |

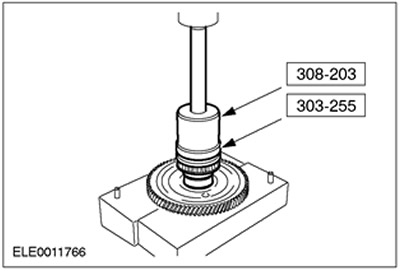

| Timing Cover Oil Seal Installer 303-255 (21-136) |

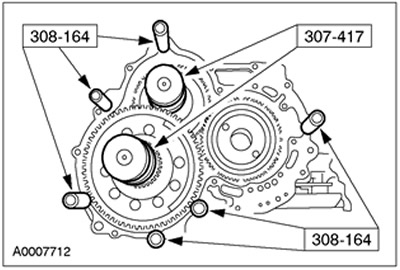

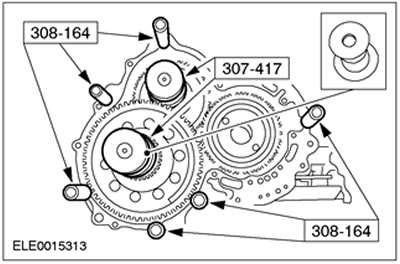

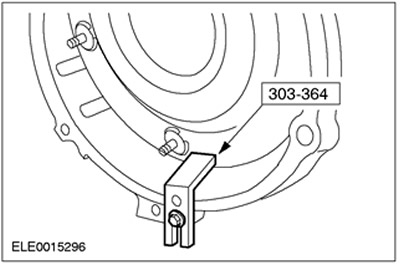

| Valve Spring Compressor 303-364 (21-158) |

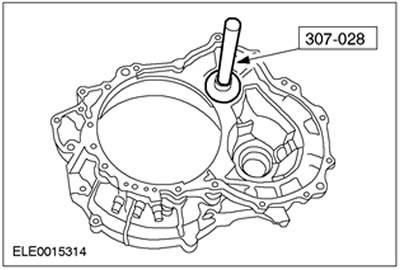

| Extended Crankcase Oil Seal Installer 307-028 (17-002) |

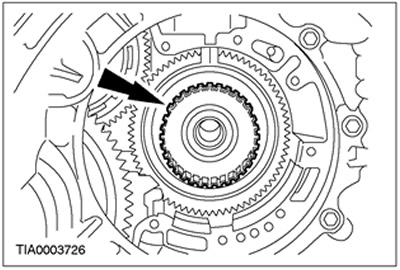

| Depth gauge for shim selection 307-300-02 (17-055-02) |

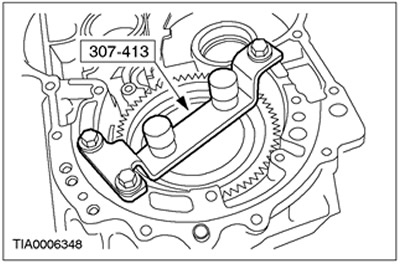

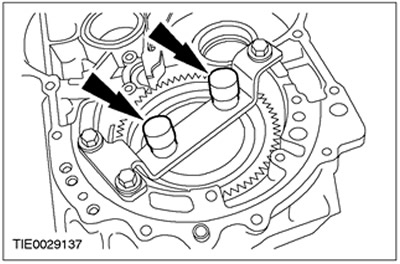

| Final Drive Lock Tool 307-413 (17-079) |

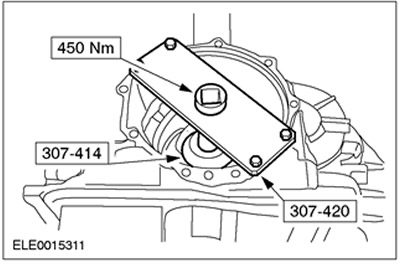

| Socket wrench for final drive nut 307-414 (17-080) |

| Sensor Alignment Tool TRS 307-415 (17-081) |

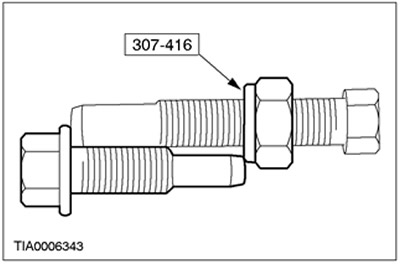

| Adjusting bolt for transmission band brake 307-416 (17-082) |

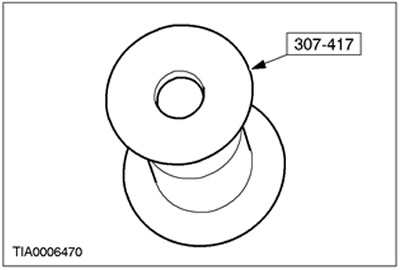

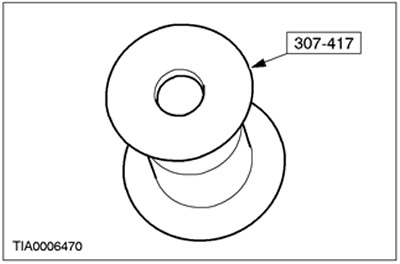

| Bearing preload gauge 307-417 (17-083) |

| Guide plate for 307-414 307-420 (17-085) |

| Pinion puller 5th gear input shaft 308-082 (16-035) |

| Distance piece for gearbox housing 308-164 (17-084) |

| 308-203 Dual Lip Seal Differential Installer (16-066) |

| Name | Specification |

| Sealant for threaded connections | TN-YS5J-M4G9107-AA |

| Loctite 5699 | WSS-M4G-320-A3 |

Assembly

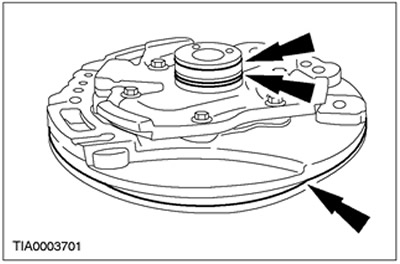

1. Using a press and special tool, install the final drive gear bearing.

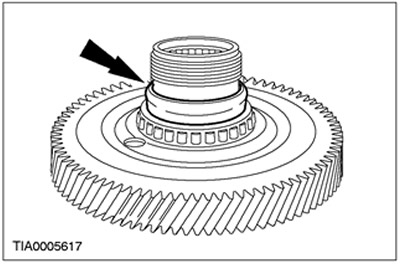

2. Install a new deformable washer.

3. Using the special tool, install the final drive gear.

4.

CAUTION: When installing the final drive gear bearing, hold the final drive gear to prevent it from falling out of the transaxle case.

Rotate the transaxle 180 degrees.

5. Using the special tools, install the final drive gear bearing.

6. Rotate the transaxle 180 degrees.

7. Using the special tool, lock the final drive gear.

8. Rotate the transaxle 180 degrees.

9.

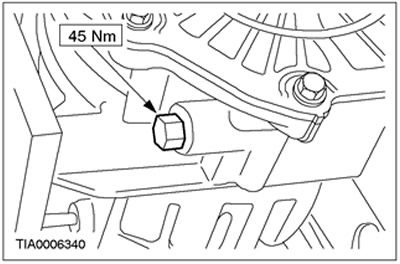

NOTE: High Torque (in the range of 400-450 Nm) necessary to collapse the deformable washer in order to ensure correct bearing preload.

NOTE: If the preload is too high, a new warp washer should be installed.

Using the special tools, tighten the nut to the correct preload.

10. Rotate the transaxle 180 degrees.

11.

NOTE: Make sure the main gear rotates.

Release the special tool.

12. Rotate the transaxle 180 degrees.

13.

CAUTION: Make sure the bearing preload is correct.

NOTE: Rotate the gear ten times to ensure proper bearing installation.

Using special tools, measure the turning torque.

14. After reaching the correct turning torque, tighten the nut to prevent it from loosening.

15. Rotate the transaxle 180 degrees.

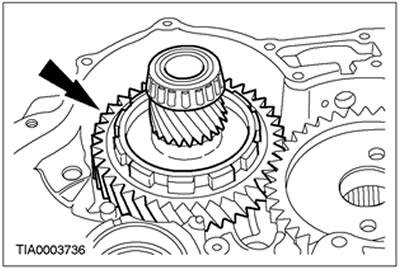

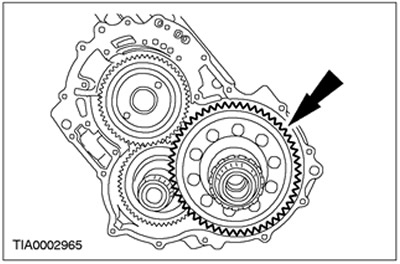

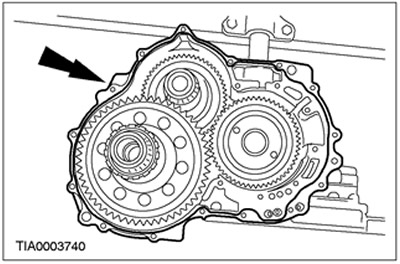

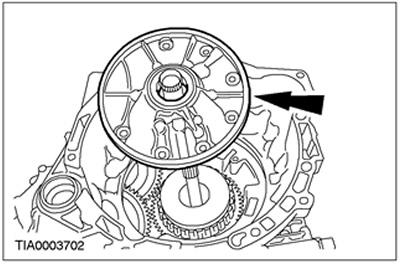

16. Install the gears of the transfer shaft into the gearbox housing in the block with the drive axle.

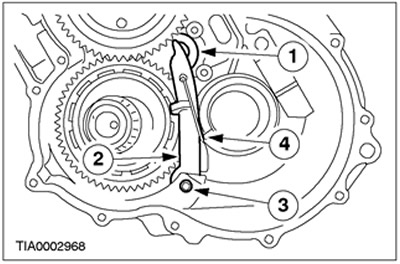

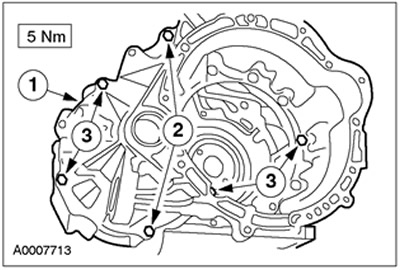

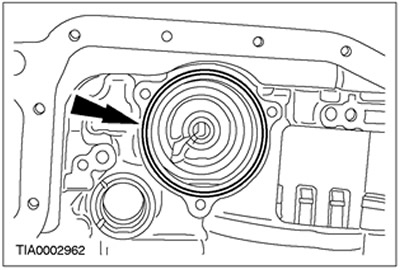

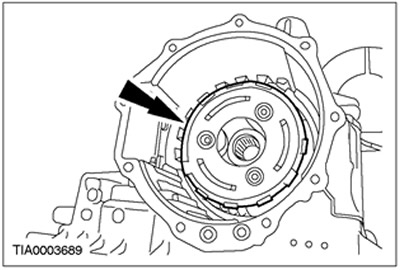

17. Install the parking latch return spring.

18. Connect the parking latch return spring.

- 1. Install the parking latch support.

- 2. Install the lever.

- 3. Install cotter pin.

- 4. Connect the latch spring.

19. Install the parking latch cover.

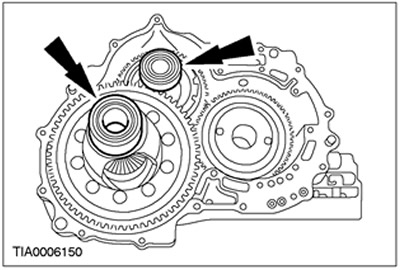

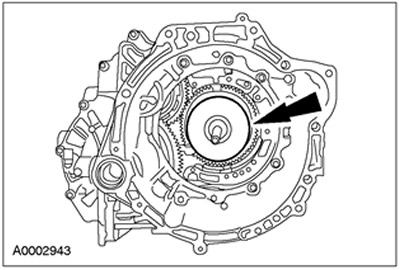

20. Install differential box assembly.

21. Install the bearing outer races.

22. Install special tools.

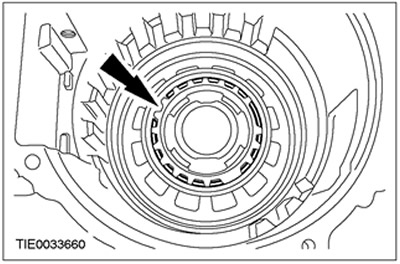

23.

NOTE: The torque converter housing cover must be installed evenly; otherwise the result will be an incorrect axial clearance.

Assemble the gearbox in a block with a drive axle to measure the axial clearance.

- 1. Install the torque converter housing.

- 2. Install the long bolts and install the torque converter housing.

- 3. Install short bolts.

24. Remove the torque converter housing.

- 1. Turn out bolts.

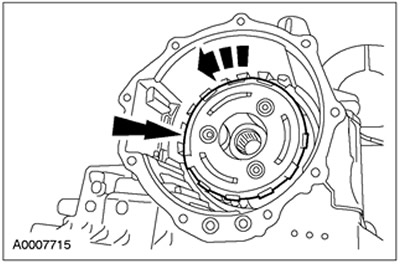

- 2. Remove the torque converter housing.

25.

NOTE: Do not move the special tool plunger; setting has already been made.

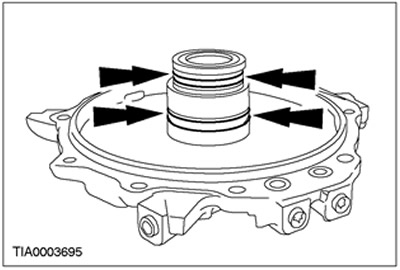

Remove special tools.

26.

NOTE: If the plunger is above the contact surface, the reading will be incorrect.

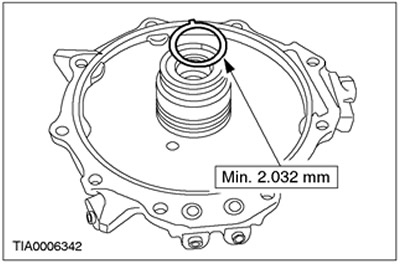

To determine the correct gearshaft shim thickness, measure the plunger depth with a special tool and select the correct shim. For more information, please refer to the chapter Specification available in this section.

27.

NOTE: If the plunger is above the contact surface, the reading will be incorrect.

To determine the correct differential shaft shim thickness, measure the plunger depth with a special tool and select the correct shim. For more information, please refer to the chapter Specification available in this section.

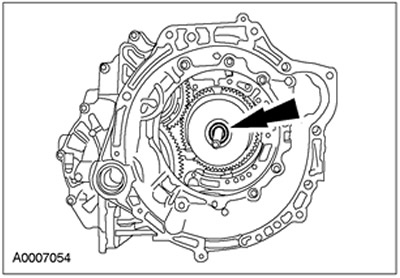

28. Using the special tool, install the correct transmission shaft gasket and differential case bearing outer race into the torque converter housing.

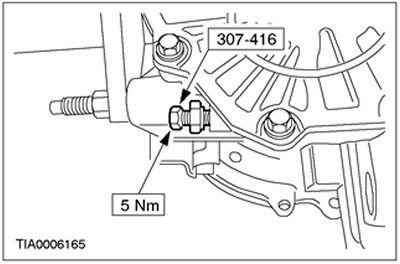

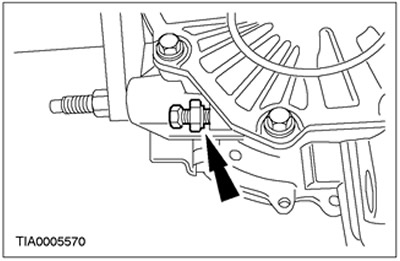

29. Using the special tool, install the correct differential shaft seal and differential case bearing outer race into the torque converter housing.

30.

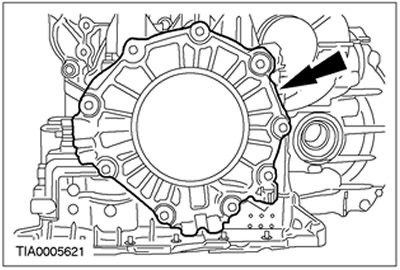

NOTE: Items should be collected within 15 minutes.

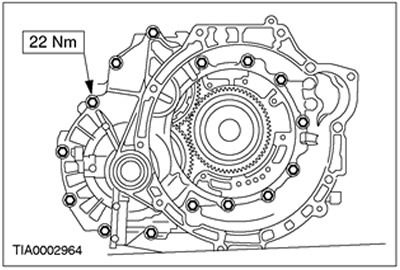

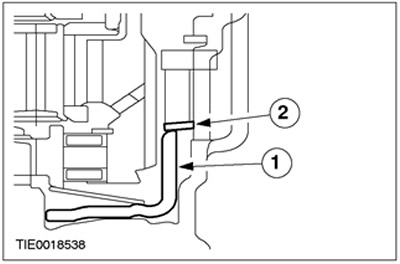

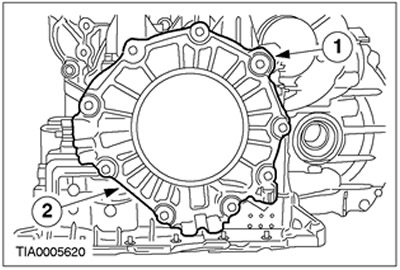

Apply a bead of Loctite 5699 1 mm thick.

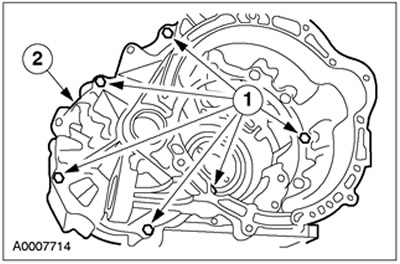

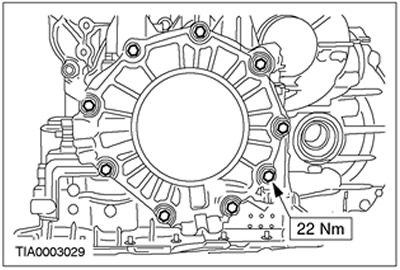

31. Install the torque converter housing.

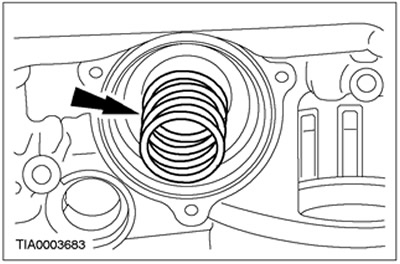

32. Install the servo piston return spring.

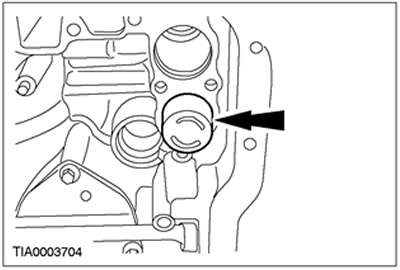

33. Install the servo piston.

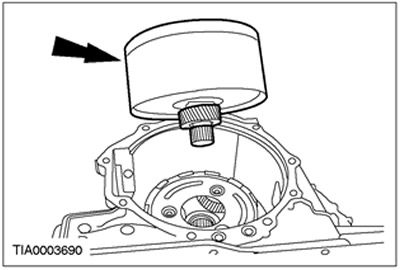

34. Install the O-ring.

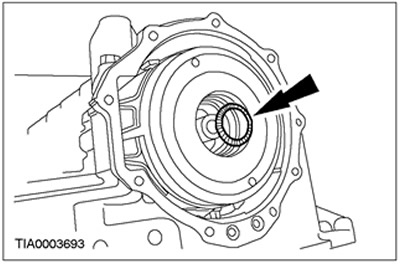

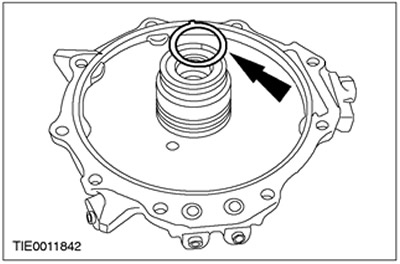

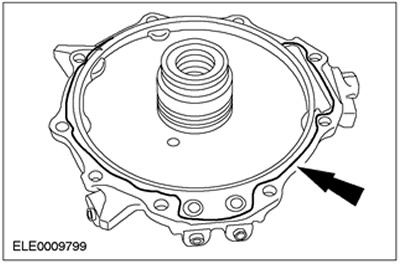

35.

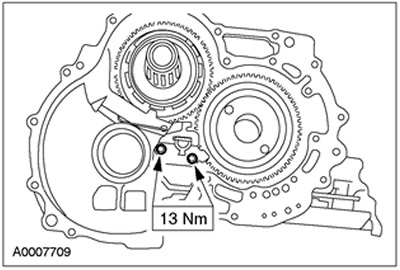

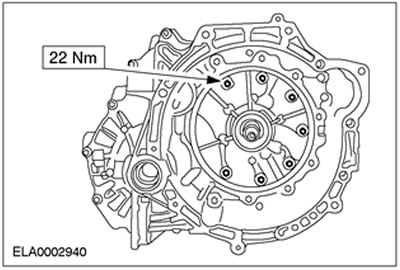

NOTE: It is necessary to install the three bolts loosely and then tighten one by one to uniformly compress the servo piston return spring.

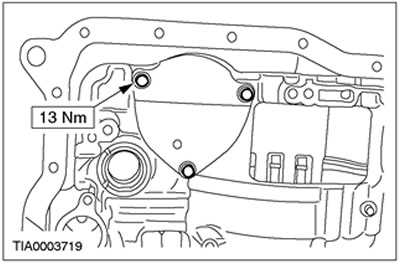

Install the servo piston cover.

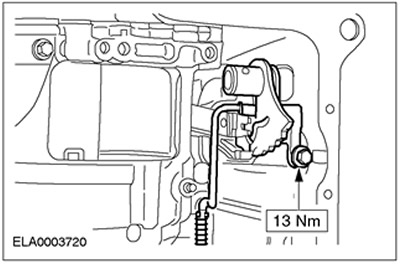

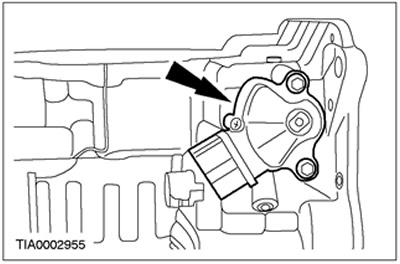

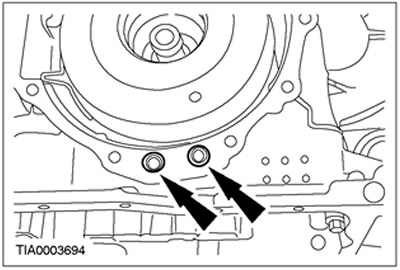

36. Install shift lever assembly and bolt.

37.

NOTE: Lubricate the O-ring before assembly.

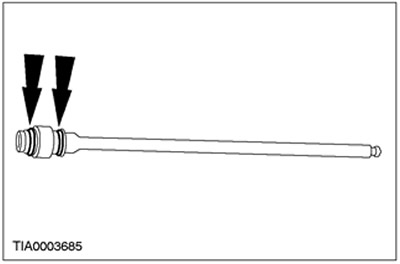

Install new O-rings on the hand lever shaft.

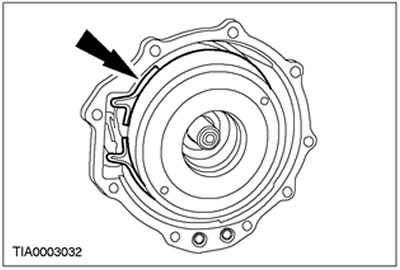

38. Install the hand lever shaft.

39.

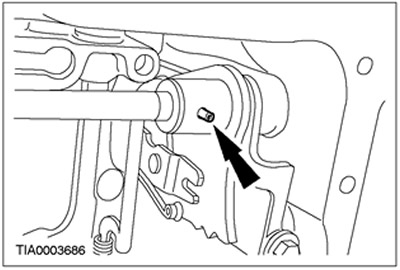

NOTE: The roll pin must not be flush with the shift lever.

Install the hand lever shaft pin.

40. Loosely install the transmission range sensor (TR).

41.

NOTE: Neutral position accumulator/drive transmission springs are thinner than accumulator springs 1-2.

Install the neutral accumulator/driving gear springs.

42. Install the neutral accumulator/driving gear piston.

43. Install accumulator springs 1-2.

44. Install accumulator piston 1-2.

45.

NOTE: Inspect seals.

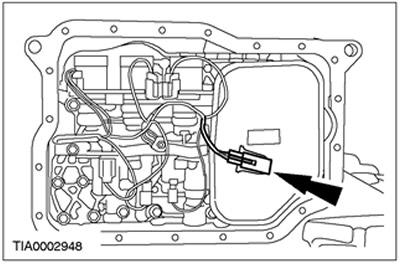

Lubricate and install the transaxle internal wiring harness connector in the transaxle assembly.

46.

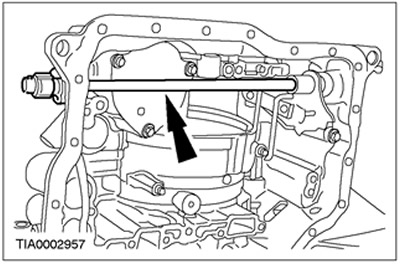

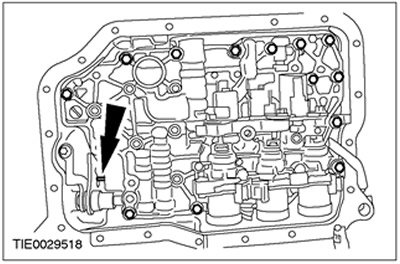

NOTE: Make sure the manual valve is located on the manual valve shift lever.

NOTE: Do not fully tighten the bolts at this stage.

Install the main control valve block.

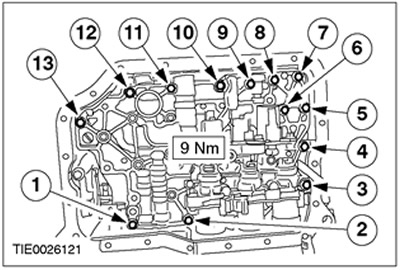

47. Tighten the main control valve block bolts. Tighten the bolts in the sequence shown.

48.

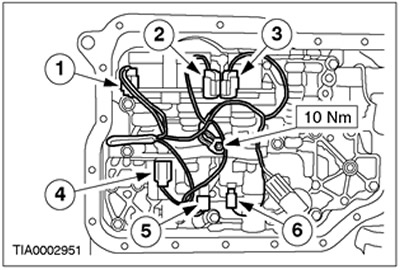

NOTE: The connectors must be mated in the same position that was noted during disassembly. The color letters of the connectors are molded on the solenoid valve block.

Install the main control box wiring, connect the plug connectors, and install the ground wire bolt.

- 1. Solenoid valve SSC; W color (neutral white)

- 2. Solenoid valve SSE: Color G (green)

- 3. SSD solenoid valve: Color L (blue)

- 4. EPC solenoid valve: Color B (black)

- 5. Solenoid valve SSA: Color N (neutral (grayish))

- 6. Solenoid valve SSB: Color B (black)

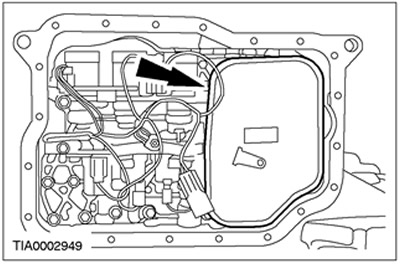

49. Install the transmission fluid filter.

50. Connect the transmission fluid temperature sensor (TFT).

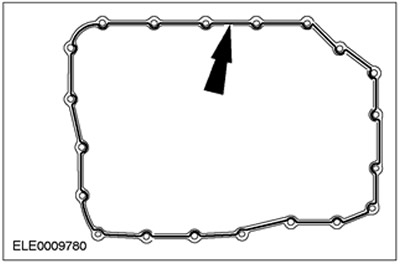

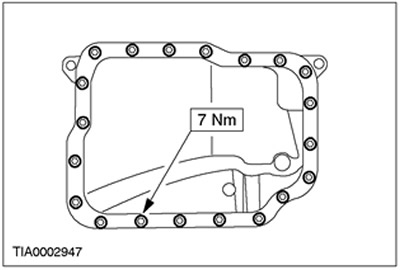

51. Apply a bead of Loctite 5699 one and a half millimeters thick to the transmission fluid sump.

52. Install the transmission fluid housing and bolts.

53. Rotate the transaxle 180 degrees.

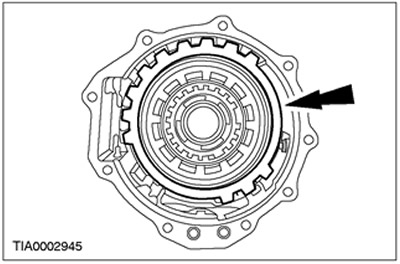

54. Install the piston of the low and reverse clutches.

55.

NOTE: Make sure the return spring is inserted with the tabs facing up

Install the low and reverse clutch return springs.

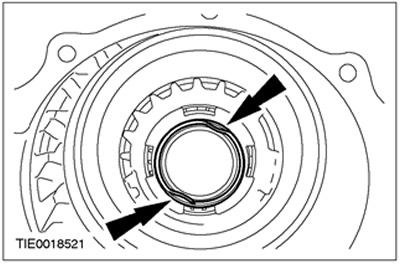

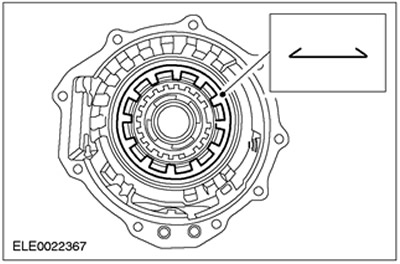

56. Install the beveled ring with the outside facing up.

57. Visually check the position of the bevelled ring.

- 1. Make sure the low and reverse clutch pistons are installed correctly.

- 2. Make sure the beveled ring is installed with the inside edge facing down.

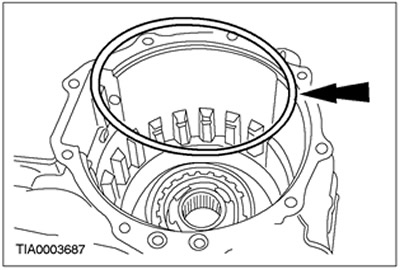

58. Install the low gear one-way clutch inner race.

59.

NOTE: The snap ring joint must be in position «10 hours».

Install the low gear one-way clutch retaining ring.

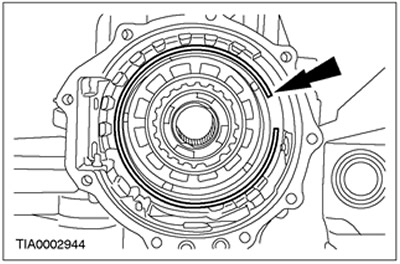

60. Install the low and reverse clutch disc and pressure plate.

61. Install the low and reverse clutch disc selective retaining ring.

- Check clearance in clutch. For more information, please refer to the chapter Specification available in this section.

62.

NOTE: Make sure the circlip is installed before installing the planetary gear assembly.

Install planetary gear assembly.

63.

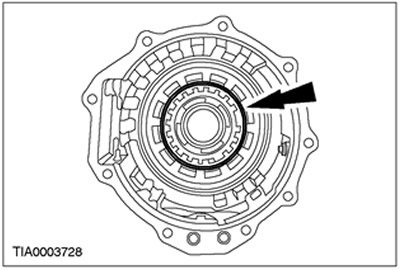

CAUTION: The edge of the planetary gear assembly must be flush with the transaxle case in the transaxle assembly.

Inspect the planetary gear assembly.

64.

CAUTION: The planetary gear must only turn in a counter-clockwise direction.

Check that the single acting clutch is installed correctly.

- Rotate the planetary gear clockwise and counterclockwise.

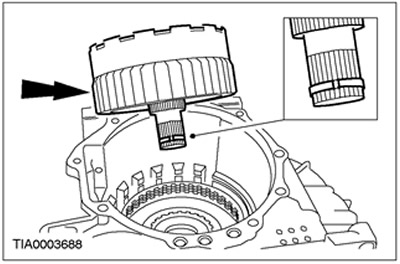

65. Establish a drum of intermediate and accelerating gears in gathering.

66. Install the intermediate and overdrive band brake.

67. Install the direct clutch cylinder thrust bearing with the rollers facing up.

68. Install new seals between end cap and crankcase.

69. Install new end cap seals.

70. Install the direct clutch hub bearing shim and additional shim to increase the total shim thickness to the prescribed value.

71.

NOTE: Make sure the cap is on both gaskets.

NOTE: Take measurements at several locations and calculate the average clearance.

Measure the clearance between the end cap of the transaxle and the transaxle.

- 1. Install the transaxle end cover to the transaxle transaxle.

- 2. Measure the clearance between the end cap of the transaxle and the transaxle.

72. Remove the end cover of the gearbox in the block with the drive axle.

73. Select and install the correct direct clutch hub bearing gasket:

- Paragraph 1 (total total thickness of the shim used when modeling the end cover of the gearbox in the block with the drive axle).

- Point 2 (measure the gap between the transaxle end cap and the transaxle case).

- Point 3 (subtract the value in step 2 from the value in step 1 to get the correct total gasket thickness).

- Item 4 (subtract the total amount for item 3 from the minimum and maximum clearances).For more information, please refer to the chapter Specifications available in this section.

- Measurement result: 0.25-0.50mm

74. Apply a 1 mm thick bead of Loctite 5699 to the transaxle end cap.

75. Install the gearbox end cover in the drive axle block.

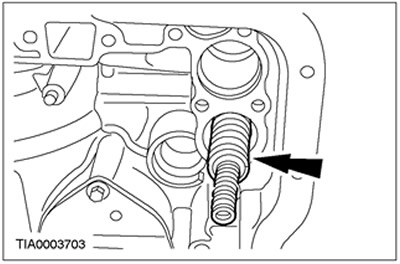

76. Using the special tool, compress the washer to specification, then loosen it three and a half turns.

77. While holding the special tool, loosely install the nut into the transaxle case, then remove the special tool without changing the position of the nut on the bolt.

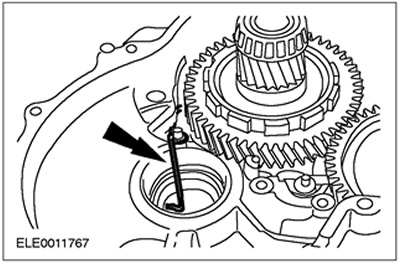

78. Using the special tool, select the band brake adjustment bolt, measured from the end of the bolt to the face of the nut, as shown.

79.

NOTE: Apply thread sealant to the bolt.

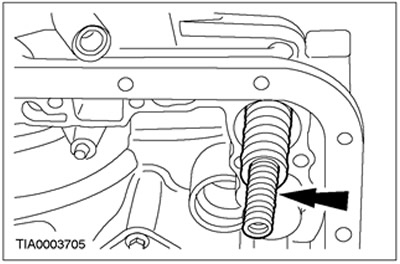

Install the band brake anchor bolt.

80. Rotate the transaxle 180 degrees.

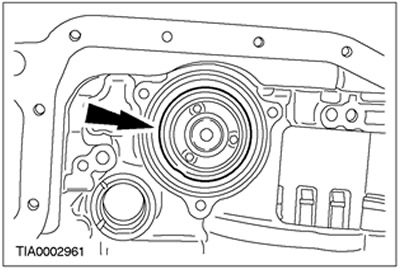

81. Install the forward clutch hub.

82. Install forward clutch assembly.

83. Install the forward clutch thrust washer.

84. Lubricate and install new pump seals.

85.

NOTE: Do not lower the pump this time.

Install the pump.

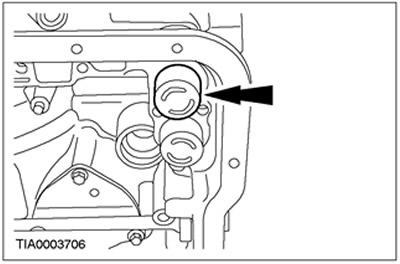

86. Install the pump.

- Use the bolts to install the pump.

- Tighten the bolts in a crosswise manner.

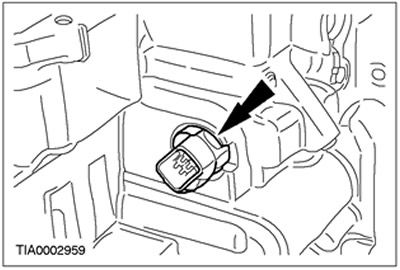

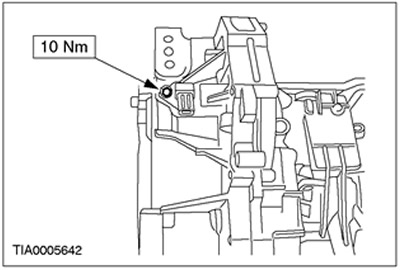

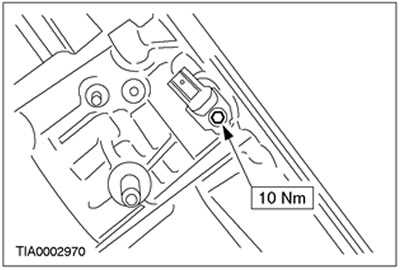

87. Install the secondary shaft speed sensor (OSS).

88.

NOTE: Apply thread sealant to the bolt.

Install the turbine shaft speed sensor (TSS).

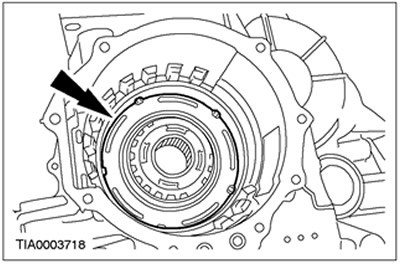

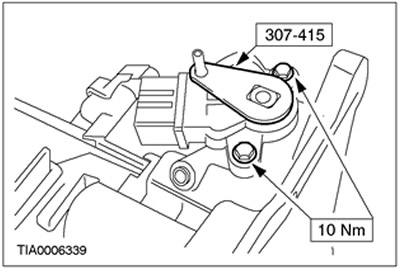

89. Using the special tool, align the TR sensor and tighten the bolts.

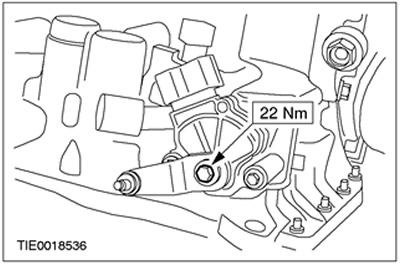

90.

CAUTION: Do not use pneumatic tools on this bolt. Hold the hand control lever while tightening the hand control lever mounting bolt.

Install the manual control lever.

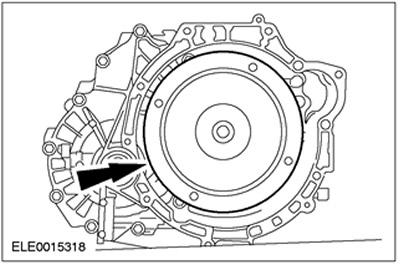

91. Install the torque converter.

92. Using the special tool, secure the torque converter.

Visitor comments