Special tool

| O-ring remover 100-010 (17-063) |

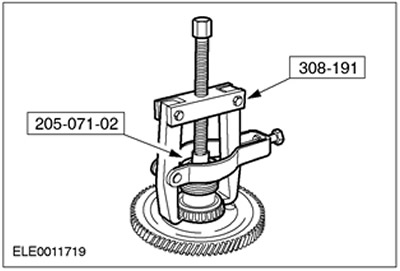

| Adapter 205-071-02 (15-026-51) |

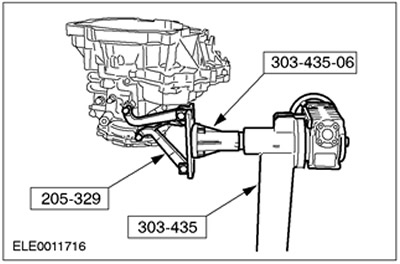

| Engine/Differential Support Bracket 205-329 (15105A) |

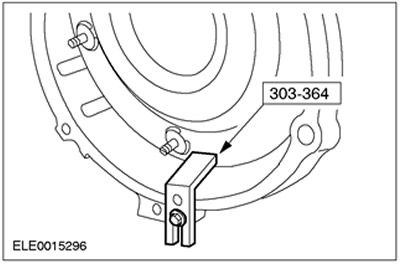

| Valve Spring Compressor 303-364 (21-158) |

| Oil sump puller 303-428 (21-179) |

| Stand 303-435 (21-187) |

| Support bracket for 303-435 303-435-06 (21031B) |

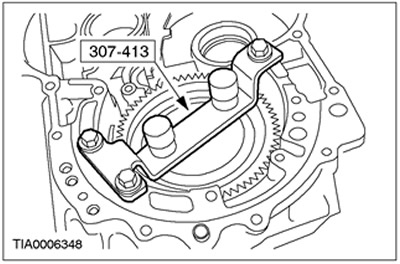

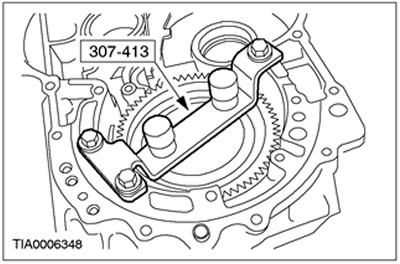

| Final drive gear holding tool 307-413 (17-079) |

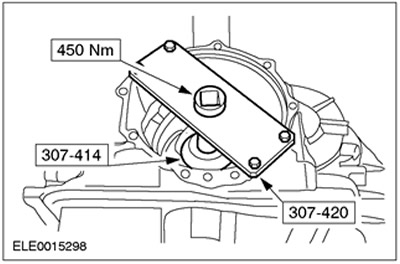

| 307-414 final drive gear nut socket wrench (17-080) |

| Lamellar wrench 307-420 (17-085) |

| 308-191 Output Shaft Needle Roller Bearing Bushing Puller (16-056) |

| Name | Specification |

| Transmission fluid for automatic transmission | WSS-M2C202-B |

| Means for cleaning metal surfaces | WSE-M5B392-A |

| Screw | M10 x 1.25 |

1.

CAUTION: If abrasive particles are found in the transaxle transmission fluid during repair (particles of clutch discs, metal chips or foreign material), the transaxle should be completely disassembled and cleaned. The lines, transmission fluid cooler and torque converter should also be thoroughly cleaned. If the lines are severely contaminated, install a new transmission fluid cooler and torque converter.

NOTE: If the clutch is worn, flush the torque converter with clean transmission fluid or an equivalent that meets Ford specifications.

In the process of disassembly, inspect the gearbox in the block with the drive axle.

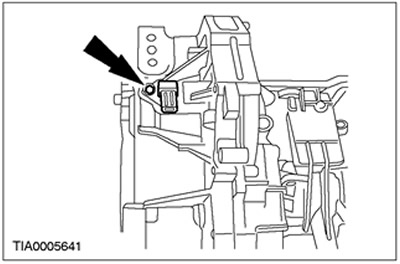

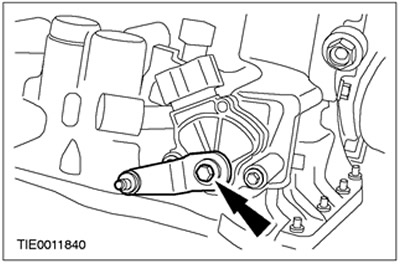

2. Remove the secondary shaft speed sensor (OSS).

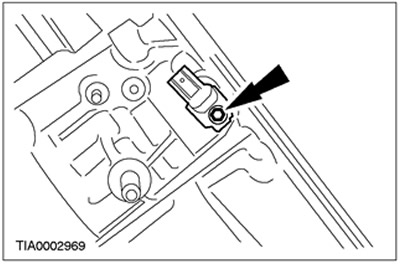

3. Remove the turbine shaft speed sensor (TSS).

4.

CAUTION: Do not use pneumatic tools.

While holding the lever, remove the manual control lever.

5. Remove the transmission range sensor (TR).

6. Remove the special tool.

7.

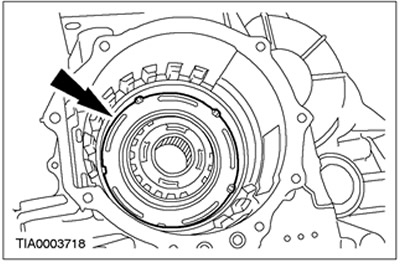

CAUTION: To avoid damaging the converter hub, do not tilt the converter when removing it.

NOTE: The torque converter is filled with transmission fluid. Drain the transmission fluid into a suitable container.

Remove the torque converter.

8. Using the special tool, fix the gearbox in the block with the drive axle.

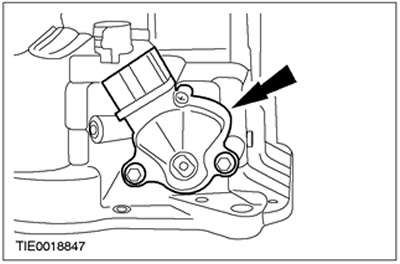

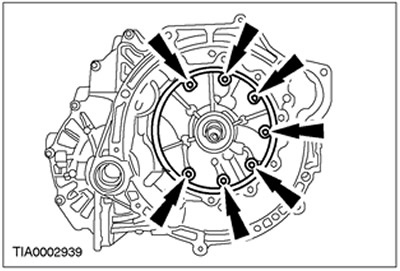

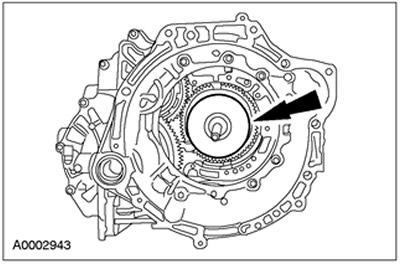

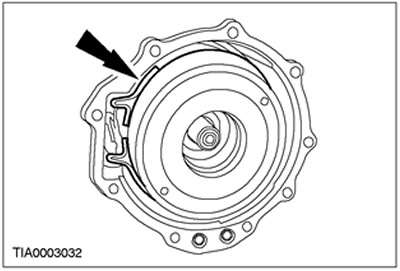

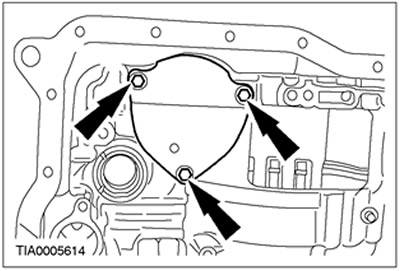

9. Turn out bolts of the pump of a working liquid.

10. Remove the pump. Install two M10x1.25 bolts in the pump and remove it.

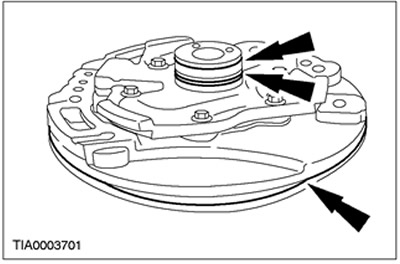

11. Remove pump seals.

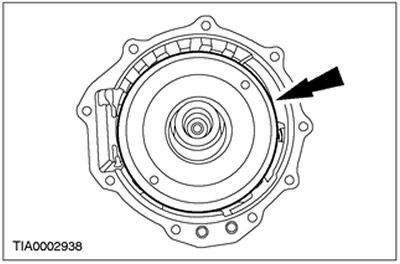

12. Remove the forward clutch thrust washer.

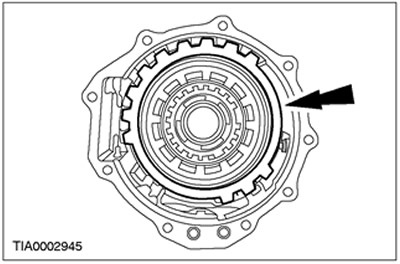

13. Remove the forward clutch assembly.

14.

NOTE: Small levers will aid in the removal of the forward clutch hub.

Remove the forward clutch hub.

15. Rotate the transaxle 180 degrees.

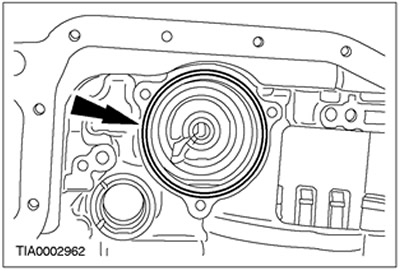

16. Remove the end cap.

17. Thoroughly remove silicone sealant from transmission fluid case and transaxle case surfaces using a metal cleaner or equivalent to Ford specification.

18. Remove the direct clutch hub bearing shim.

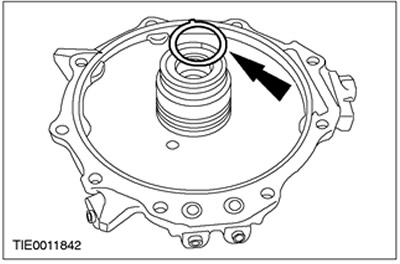

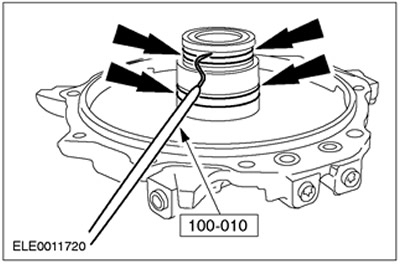

19. Using the special tool, remove the end cap seals.

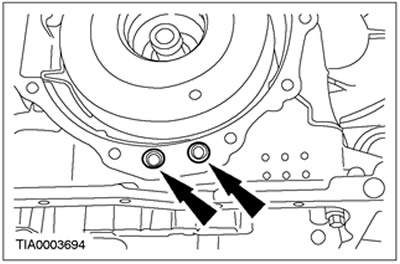

20. Remove seals located between end cap and crankcase.

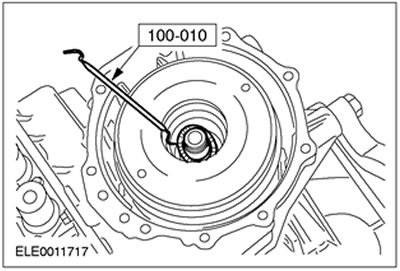

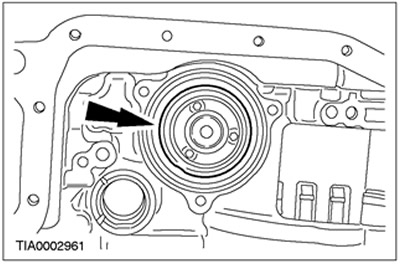

21. Using the special tool, remove the direct clutch cylinder thrust bearing.

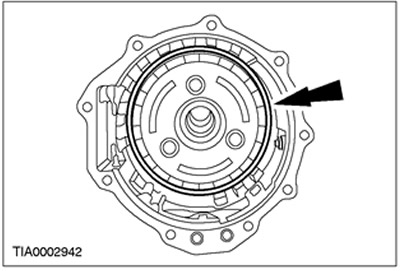

22. Remove the intermediate and overdrive band brake anchor bolt.

23. Remove the intermediate and overdrive band brake.

24. Remove the intermediate and overdrive band brake drum assembly.

25. Remove the planetary gear assembly.

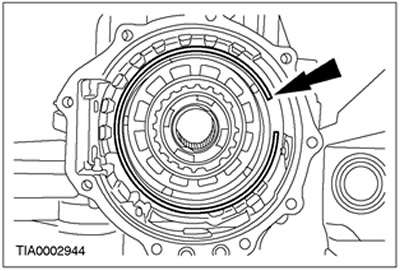

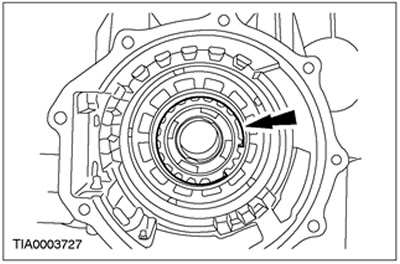

26. Remove the retaining ring for the low and reverse clutch discs.

27. Remove the discs, pressure plate and beveled ring of the low and reverse clutch.

28. Remove the low gear one-way clutch retaining ring.

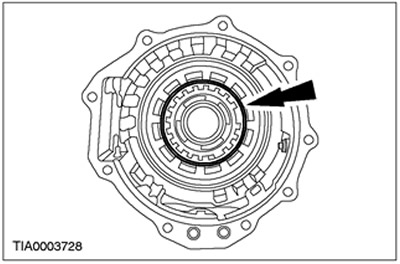

29. Remove the low gear one way clutch inner race.

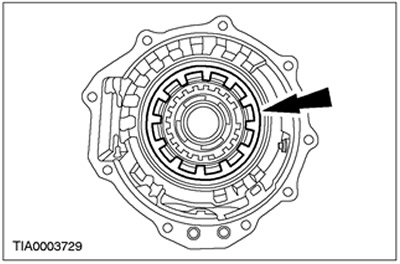

30. Remove the low and reverse clutch return spring.

31. Remove the low and reverse clutch piston.

32. Remove the transmission fluid housing and drain the fluid from it using a suitable pan.

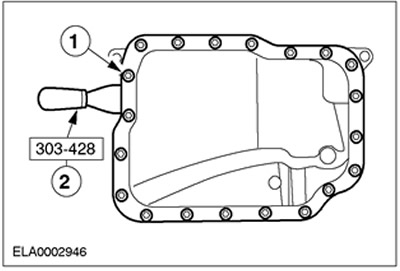

- 1. Turn out bolts.

- 2. Using the special tool, separate the transmission fluid housing from the transaxle transaxle.

33. Thoroughly remove silicone sealant from transmission fluid case and transaxle case surfaces using a metal cleaner or equivalent to Ford specification.

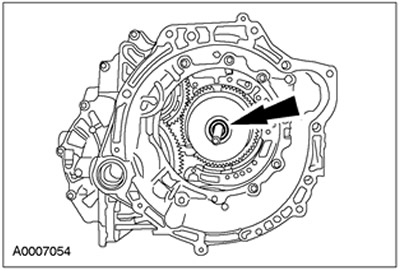

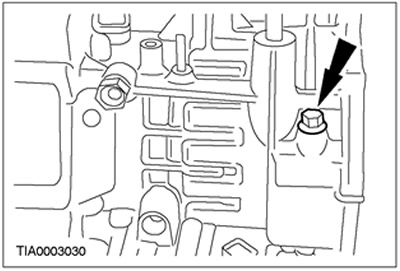

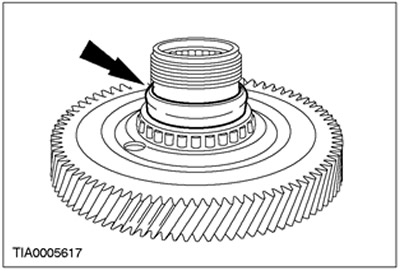

34. Remove the transmission fluid temperature sensor (TFT).

35. Remove the transmission fluid filter.

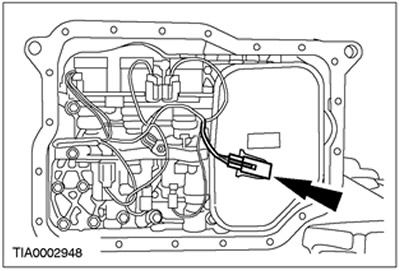

36.

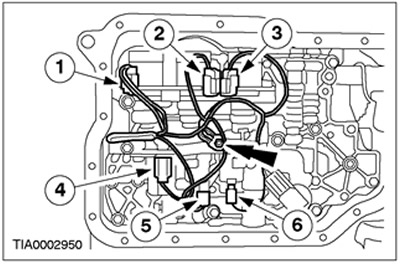

NOTE: Note the location of the main control wiring harness connectors as they can only be connected in the same positions. The color letters of the connectors are molded on the solenoid valve block.

Remove the ground wire bolt. Disconnect the plug connectors and remove the wiring harness.

- 1. Solenoid valve SSC; W color (white)

- 2. Solenoid valve SSE: Color G (green)

- 3. SSD solenoid valve: Color L (blue)

- 4. EPC solenoid valve: Color B (black)

- 5. Solenoid valve SSA: Color N (neutral (grayish))

- 6. Solenoid valve SSB: Color B (black)

37.

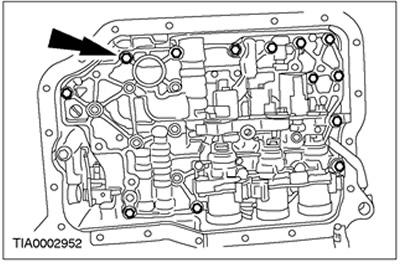

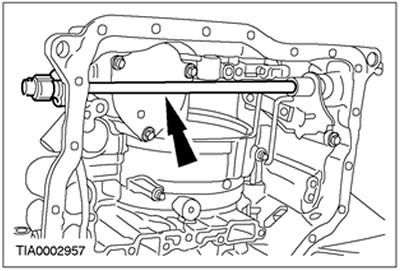

NOTE: Note the location of the longer bolts.

Turn out 13 bolts of fastening of the main block of valves of management.

38.

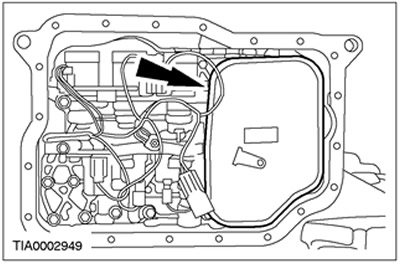

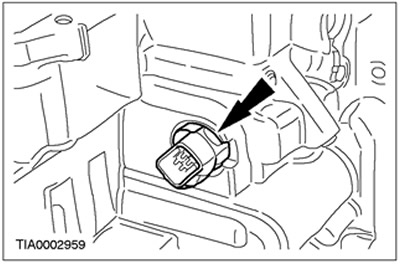

NOTE: Squeeze the locking elements on the plug connector.

Remove the plug connector of the internal wiring harness of the transaxle in the block with the drive axle.

39.

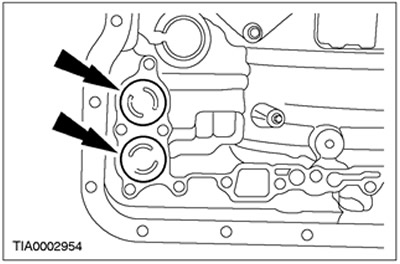

NOTE: Each of these two accumulators has two springs. All four springs are different sizes.

NOTE: For reassembly, note the size and location of the accumulator springs.

Remove pistons and accumulator springs.

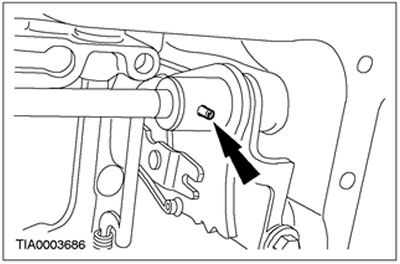

40. Remove roll pin from hand lever.

41. Remove the hand lever shaft.

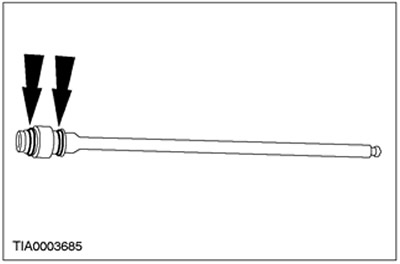

42. Remove the O-rings from the hand lever shaft.

43. Remove the control lever assembly.

44.

CAUTION: The intermediate and overdrive band brake servo cover is spring loaded. The bolts should be turned out evenly until the plate is unloaded, then completely turn out the bolts.

Remove the intermediate and overdrive band brake servo cover.

- Turn out bolts.

- Remove the intermediate and overdrive band brake servo cover.

45. Remove the O-ring.

46. Remove the intermediate and overdrive band brake servo piston.

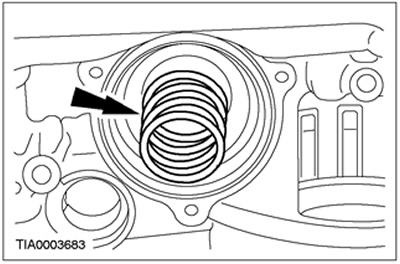

47. Remove the intermediate and overdrive band brake servo piston return spring.

48. Rotate the transaxle 180 degrees.

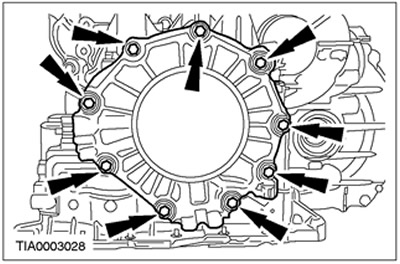

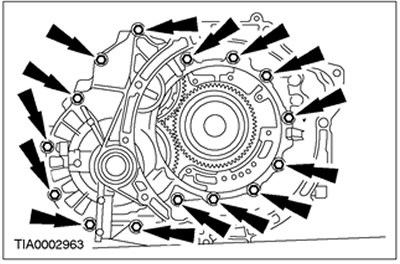

49. Remove the bolts and separate the torque converter housing from the gearbox housing in the block with the drive axle.

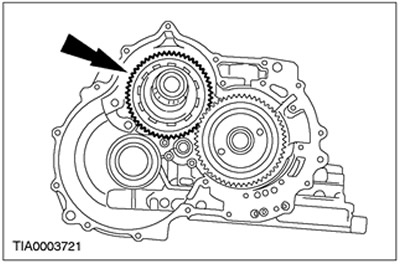

50. Remove the differential assembly.

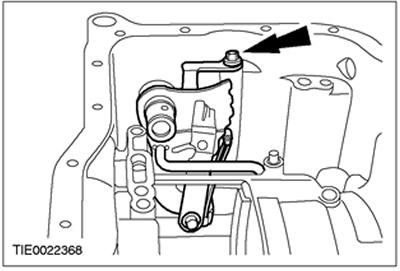

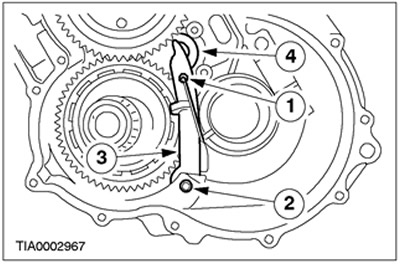

51. Remove the parking latch cover assembly.

52. Remove the parking latch support.

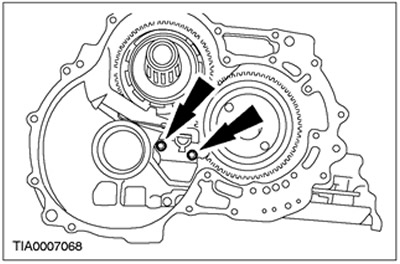

- 1. Disconnect the spring.

- 2. Remove the pin.

- 3. Remove the lever.

- 4. Remove the parking latch support.

53. Remove the spring.

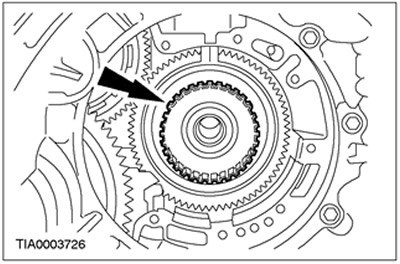

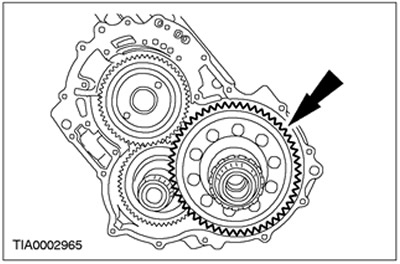

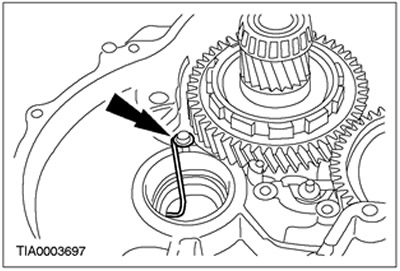

54. Remove the transmission shaft gear.

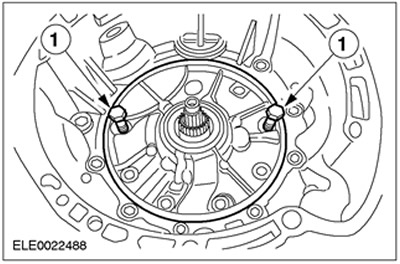

55. Using the special tool, block the final drive gear.

56. Rotate the transaxle 180 degrees.

57.

NOTE: Pull lockout sleeve away from final drive pinion bearing nut.

Using the special tool, remove the main gear bearing nut.

58. Rotate the transaxle 180 degrees.

59. Remove the special tool.

60.

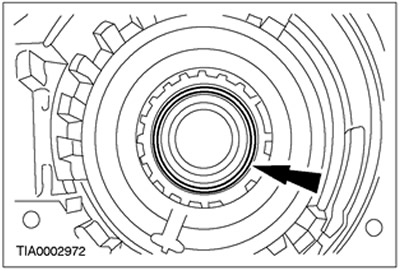

CAUTION: When removing the bearing, hold the final drive pinion to prevent it from falling out of the transaxle case.

Rotate the transaxle 180 degrees.

61. Remove the final drive gear bearing by lightly tapping the end of the final drive gear. Remove the final drive gear.

62. Remove the deformable washer and discard it as no longer needed.

63. Using the special tool, remove the final drive gear bearing.

64. Thoroughly clean the surfaces of the torque converter housing and transaxle case using a metal cleaner or equivalent to Ford specification.

Visitor comments