General information

The Focus is powered by Zetec-SE engines with a displacement of 1.4 liters and an output of 55 kW / 75 hp. and a working volume of 1.6 liters and a power of 74 kW / 100 hp. respectively.

The Zetec-SE motor is an all-aluminum construction. Both engine options meet the stringent requirements of the EEC-96/D4 emission standard.

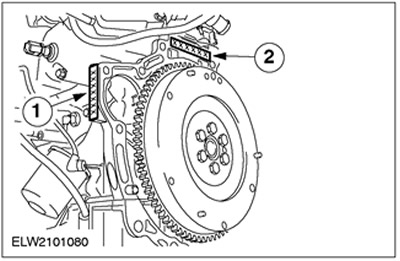

Location of serial number and engine code

| Pos. | Spare Part No | Name |

| 1 | - | Engine code for 1.4L engine up to MY 2000.25 (Stage II emission standard/Europe excluding Germany) - FXDA |

| - | Engine code for 1.6L engine up to MY 2000.25 (Stage II emission standard/Europe excluding Germany) - FYDA | |

| - | Engine code for 1.4L engine up to model year 2001 (Emissions standard Stage III/Europe except Germany): FXDB | |

| - | Engine code for 1.6L engine from model year 2001 (Emissions standard Stage III/Europe except Germany): FYDB | |

| - | Engine code for 1.4L engine up to MY 2000.25 (Emission standard D4/Germany) - FXDC | |

| - | Engine code for 1.6L engine up to MY 2000.25 (Emission standard D4/Germany) - FYDC | |

| - | Engine code for 1.4L engine up to model year 2001 (Emission standard D4/Germany): FXDD | |

| - | Engine code for 1.6L engine from model year 2001 (Emission standard D4/Germany): FYDD | |

| - | Engine code for 1.6L engine from 2000 model year (Emission standard ECE-R 15/04): FYDG | |

| 2 | - | Date of manufacture |

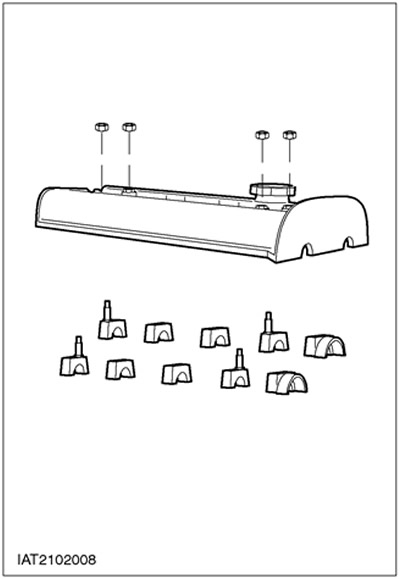

Cylinder head cover

NOTE: The cylinder head cover is made of magnesium, the gasket is vulcanized in position and cannot be replaced separately. There is no need to install a new cylinder head cover, including gasket, each time the cover is removed. Therefore, inspect the gasket first and install a new cylinder head cover only if the gasket is damaged.

The cylinder head cover is attached to four camshaft bearing caps. To seal these studs, four rubber plugs with torque limiters are used. In the event of a leak, these plugs can be replaced individually. To install, these rubber plugs should be lightly coated with engine oil. Wipe off excess oil using a clean cloth. When installing a new cylinder head cover, four new plugs must be used. They are supplied with the cylinder head cover.

Camshafts

CAUTION: Before installing the camshafts, they must be lubricated with engine oil.

CAUTION: The camshaft bearing caps must be tightened gradually following the prescribed tightening sequence.

NOTE: The timing belt pulleys are located on the camshafts.

When installing new camshafts, check the running surfaces of the bearings. If damage is found, replace the cylinder head and camshaft bearing caps if necessary.

The exhaust camshaft has an additional cam for the camshaft position sensor (CMP sensor).

Both camshafts have a 21mm forged hexagon used to turn the camshafts.

At the ends of both camshafts there is a groove into which a tool is inserted to set the top dead center.

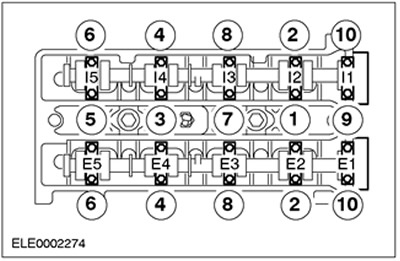

The numbering of the bearing caps starts from the side where the timing belt is located, and is marked:

- I1 - on the inlet side

- E1 - on the exhaust side

The front bearing caps are precisely positioned on the cylinder head by means of guide bushings. These covers are installed on the sealant.

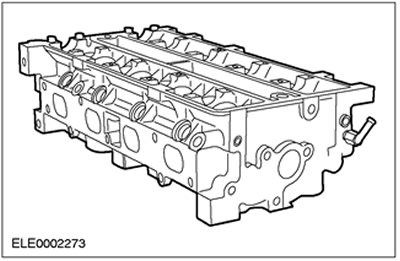

Cylinder head

CAUTION: Repairing the threads in the cylinder head is not permitted.

CAUTION: Do not rework the mating surface of the cylinder head.

CAUTION: Machining valve seats and valve guides is not permitted.

CAUTION: When installing a new CHT sensor, be careful not to damage the pin.

NOTE: Cylinder head temperature sensor (CHT) located next to the spark plug for cylinder #3. It directly measures the temperature of the cylinder head, i.e. does not use coolant temperature. When installed, the sensor is deformed and cannot be reused after removal.

NOTE: When installing new valves, they must be lapped (grind) without mechanical processing of saddles.

The cylinder head is made of aluminum and is precisely positioned on the cylinder block by two guide bushings.

When replacing, the cylinder head is delivered already equipped with valves and camshaft bearing caps. Studs should be replaced.

To ensure proper sealing of the cylinder head, the maximum allowable flatness of the mating surface of the cylinder block must be 0.05 mm.

Cylinder head gasket

NOTE: The cylinder head gasket can only be installed correctly in one position.

The cylinder head gasket is a laminated steel gasket that should be replaced every time it is removed.

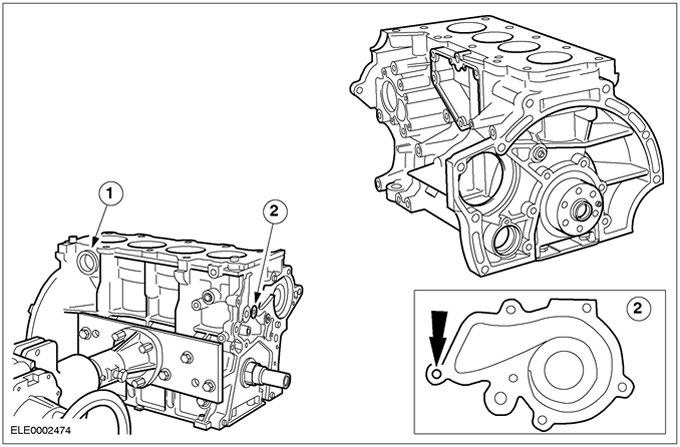

Cylinder block

CAUTION: Always place the cylinder block on a soft surface to prevent damage to the cylinder head mating surface.

CAUTION: Unlike option 1.6, thread repair is not allowed on option 1.4.

CAUTION: Machine block mating surfaces are not permitted.

CAUTION: Be careful not to damage the water pump impeller when installing or removing.

The cylinder block is a die-cast aluminum casting with cylinder liners made of cast iron.

When replacing, the cylinder block is supplied complete with a crank mechanism and pistons, along with plugs for oil galleries and coolant drain plugs.

- 1. For Northern European countries, a heating coil can be inserted into the plug hole.

- 2. In the 1.6L engine block, the threaded hole for the coolant pump can be repaired by installing a threaded bushing. When doing this, do not exceed a hole depth of 14 mm and a thread length of 11 mm.

Do not reuse the coolant drain plug. Since 09.1999, the cylinder block is no longer equipped with coolant drain plugs.

To ensure proper sealing of the cylinder head, the maximum allowable flatness of the mating surface of the cylinder block must be 0.05 mm.

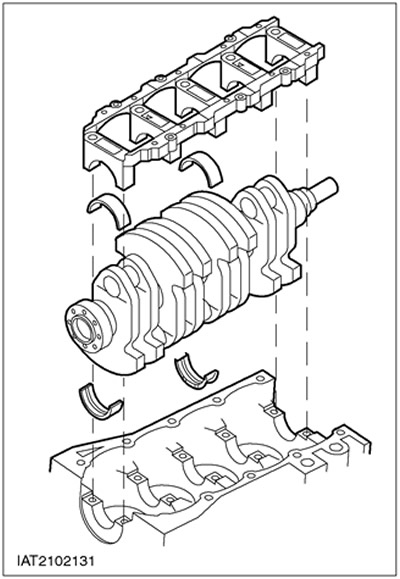

Crank mechanism

NOTE: Due to the very small clearances in the bearings and bearing shells, the crankshaft components cannot be replaced separately. Measuring clearances in bearings (main bearings and bearings of the lower heads of connecting rods) cannot be done using traditional methods.

Never disassemble the crank mechanism.

The crankshaft is attached to the cylinder block by means of a lower crankcase made of aluminum.

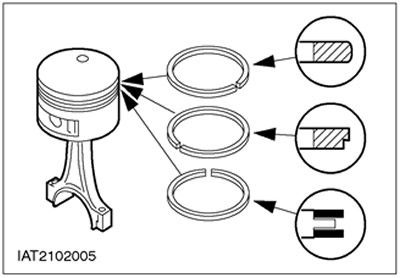

Pistons

CAUTION: Pistons must not be removed.

There are no oversized pistons.

The pistons are made of aluminum alloy and are equipped with three piston rings:

- Rectangular ring (upper)

- stepped ring (average)

- Oil scraper ring (bottom)

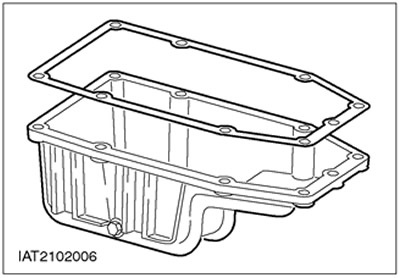

Oil sump

The oil pan is made of aluminium.

When installing, align the oil sump so that it is flush with the cylinder block.

Spacers are not included.

When tightening, follow the prescribed tightening sequence and the prescribed tightening torque.

Engines manufactured before 10.1999 inclusive

The oil pan gasket should be replaced every time (crankcase) reinstallation.

Before refitting the oil pan, apply the prescribed sealant to the cylinder block joints, oil pump flange, and bearing surface of the crankshaft rear oil seal retainer.

Engines manufactured since 11.1999

Oil sump gasket removed and replaced with "liquid gasket".

Valve mechanism

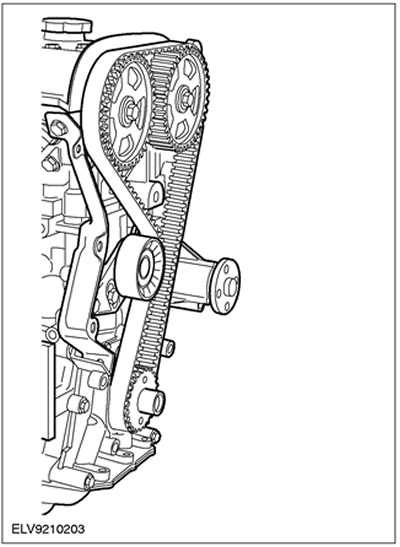

Two overhead (above the cylinder head) The camshafts are driven by the crankshaft through the timing belt. They act on the valves through the pushers.

Valve clearances are adjusted using gaskets that are located on top of the pushrods. They should be checked every 100,000 Km.

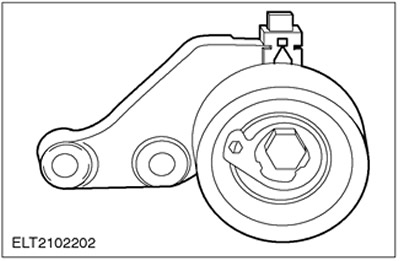

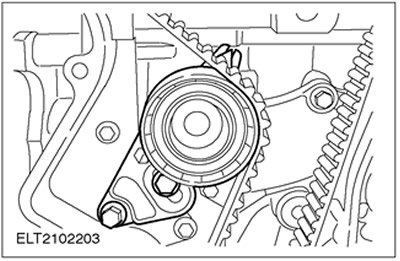

Two timing belt tensioners are used:

Timing belt tensioner with cam

Groove Timing Belt Tensioner

The timing belt should be replaced after 150,000 km or 10 years.

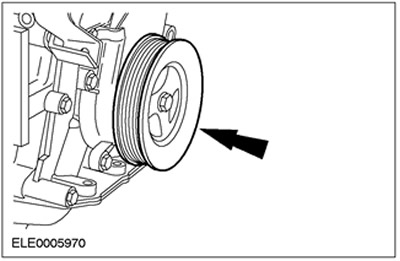

Pulley/vibration damper (damper) crankshaft

CAUTION: After loosening or tightening the crankshaft pulley/damper bolt, check the alignment of the camshafts and the crankshaft, i.e. valve timing.

CAUTION: The crankshaft pulley/damper bolt should only be used once.

CAUTION: Any gaskets that are removed with the engine components must be replaced when the components are reinstalled.

NOTE: If the bolt is not tightened to specification, the crankshaft pulley/vibration damper and the crankshaft timing belt pulley that installs behind it can rotate freely on the crankshaft.

In order to carry out adjustment and inspection work, the crankshaft pulley/vibration damper must be properly installed.

Visitor comments