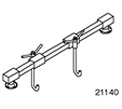

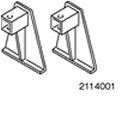

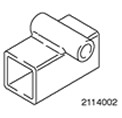

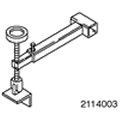

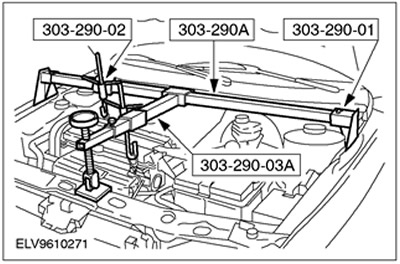

Special tool

| Engine support beam 303-290 (21-140) |

| Adapter for 303-290 303-290-01 (21-140-01) |

| Adapter for 303-290 303-290-02 (21-140-02) |

| Adapter for 303-290 303-290-03 (21-140-03) |

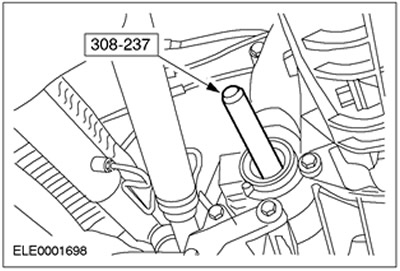

| Axle puller 308-237 (16-087) |

General equipment:

- Jack for gearbox

- Fixing clamp

Withdrawal

1. General notes:

- Note the radio key code.

- Mark the pre-programmed radio stations.

CAUTION: Disconnect the ground wire from the battery.

- The position of the engine mounts and engine roll limiters in the description corresponds to the view directed from the gearbox to the engine.

- Items where actions apply to specific variants and not to all vehicles are marked with a special note.

- If necessary, remove the clamps and install new ones when reassembling.

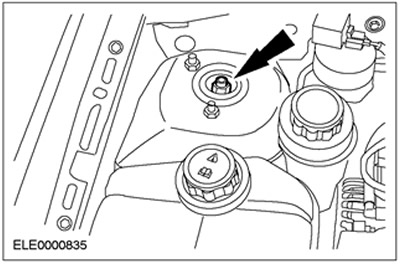

2.

NOTE: Use an Allen wrench to stop the piston rod from turning.

Loosen left and right suspension strut nuts five turns.

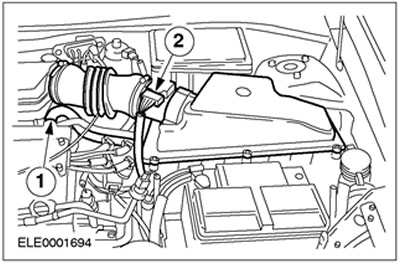

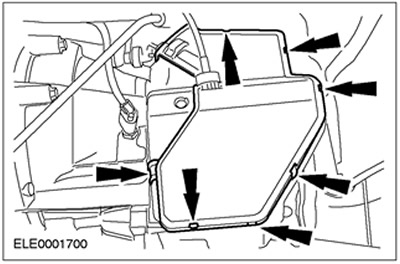

3. Remove the air filter.

- 1. Disconnect the crankcase ventilation hose.

- 2. Disconnect the MAF sensor connector.

4. Remove the air filter.

- Turn out bolts and remove an accumulative chamber together with a final hose and the air filter.

5. Disconnect the vehicle speed sensor electrical connector (VSS).

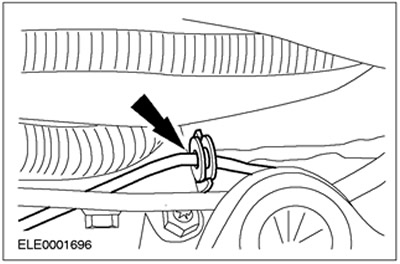

6. Remove the clutch hydraulic line from the lug.

7.

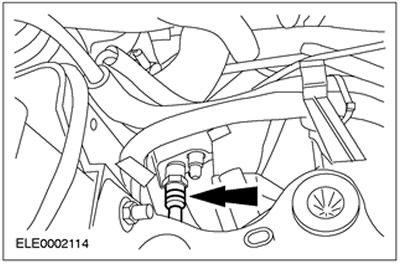

CAUTION: Brake fluid leakage. Observe precautions for handling brake fluid.

Disconnect the pressure line from the clutch slave cylinder.

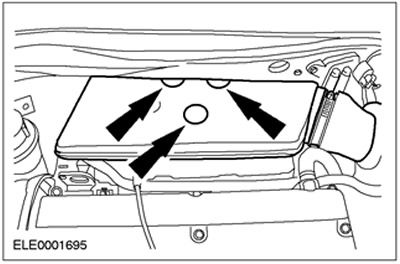

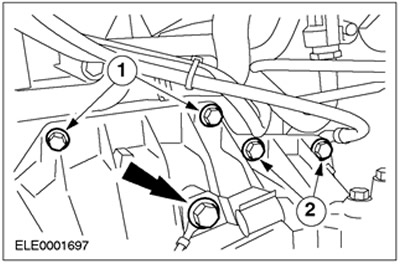

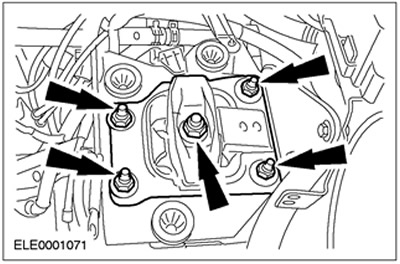

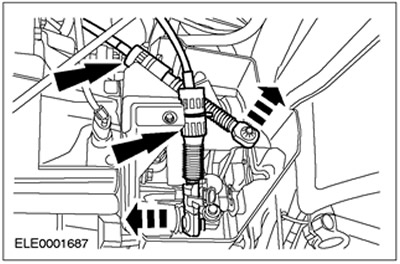

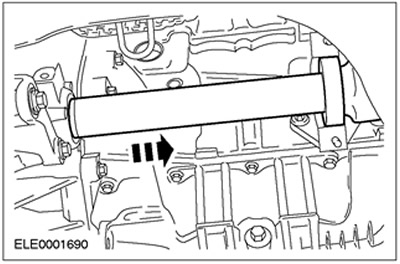

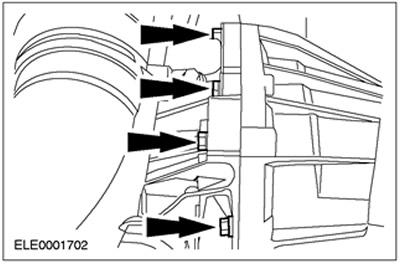

8. Turn out the top bolts.

- 1. Flange bolts

- 2. Starter bolts

- Disconnect the ground wire.

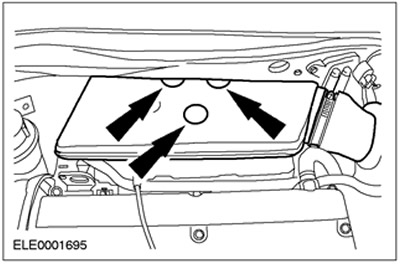

9. Connect special tools.

10. Remove the rear engine mount.

11. Remove an arm of a back support of the engine.

12. Lower the engine/transmission as far as possible. Use a special tool.

13. Raise the car. See Section 100-02 for more information.

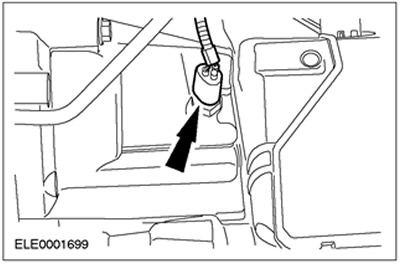

14. Disunite a socket of the switch of lanterns of a backing.

15. Open the shift and select cable cover.

16. Disconnect shift cables and gear selection.

- Remove the shift and select cables from the bracket. To do this, turn the ring clockwise.

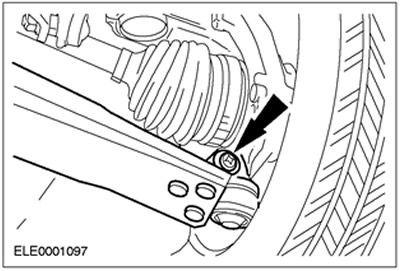

17. Disconnect the ball joints of the lower suspension arms on both sides (right side shown).

18. Disconnect an arm of fastening of the intermediate bearing of the right semiaxis.

- Discard the mounting bracket and intermediate bearing nuts as they are no longer needed.

19.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. The outer hinge should not be tilted more than 45 degrees.

CAUTION: Do not damage the oil seal.

NOTE: Plug the gearbox openings to prevent oil leakage and dirt from entering.

Disconnect the right axle shaft from the gearbox and secure it to the side. Collect the oil in a suitable container.

20.

CAUTION: Support axle shaft. The inner hinge should not be tilted more than 18 degrees. The outer hinge should not be tilted more than 45 degrees.

CAUTION: Do not damage the oil seal.

NOTE: Plug the gearbox openings to prevent oil leakage and dirt from entering.

Disconnect the left axle shaft from the gearbox and secure it to the side.

- Collect the oil in a suitable container.

- Discard the snap ring as it is no longer needed.

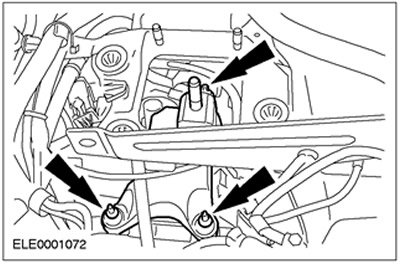

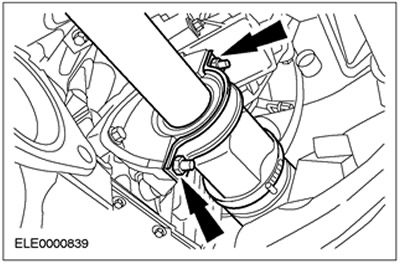

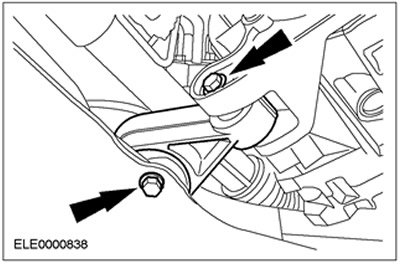

21. Remove the engine roll limiter.

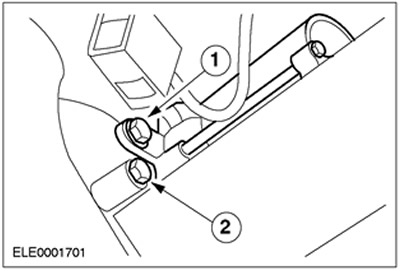

22. Turn out a bolt of a flange and move a starter aside.

- 1. Starter bolt

- 2. Flange bolt

23. Turn out the bottom bolts of a flange.

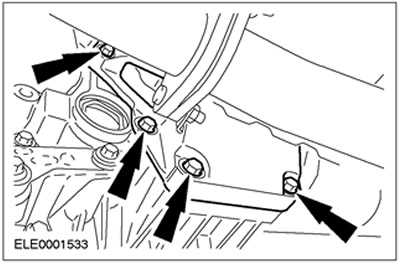

24.

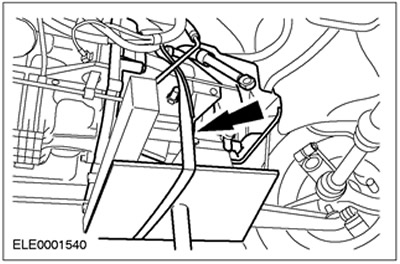

NOTE: Support the transmission with a transmission jack.

Remove the four flange bolts.

25. Fix a transmission, using for this purpose a fixing collar and lower it, using a Jack for a transmission.

Visitor comments