NOTE: Determine the cause of the damage and correct it.

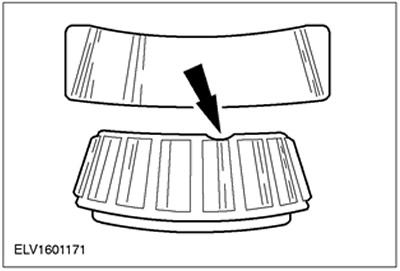

Check for damage to the bearing cage at the top or side or in the hole area due to incorrect use of the special tool or the use of an unsuitable tool.

- Install a new bearing if necessary.

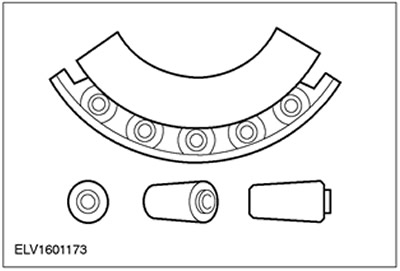

2. Check for discoloration of the tapered roller ends due to insufficient lubrication or overheating, possibly due to excessive preload.

- Install a new bearing and new seals if necessary.

- Check correct bearing lubrication.

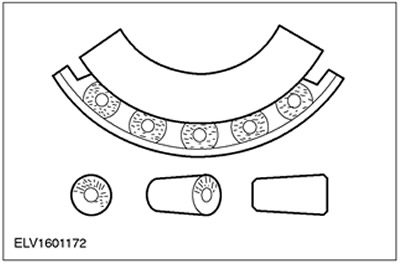

3. Check for wear at the ends of the tapered rollers due to improper installation, excessive preload, or improper bearing fit.

- Install a new bearing and new seals if necessary.

- Check correct bearing lubrication.

4. Check for gray or grey/black bearing surfaces with deposits between the rollers.

- Install a new bearing and new seals if necessary.

- Check correct bearing lubrication.

5. Check for static load grooves on the bearing ring surfaces.

- Install a new bearing if the surface is uneven or the bearing makes noise.

6.

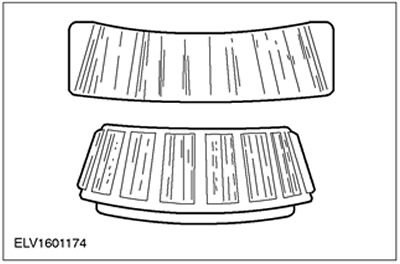

NOTE: Overheating may result in loss of surface hardness.

Check for dark blue discoloration due to overheating (yellow or brown coloration is normal) due to excessive preload or insufficient lubrication.

- Install a new bearing, new seals and other items as needed.

7. Check surfaces for abrasion caused by metal fatigue.

- Install a new bearing and clean any other affected items if necessary.

Visitor comments