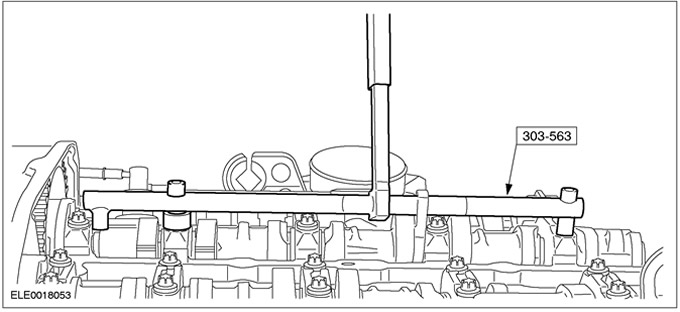

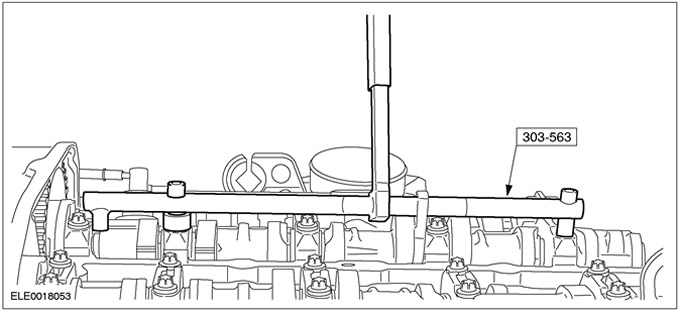

Special tool

| Spring Compressor for Valve Clearance Adjustment 303-563 (21-218) |

| Pliers for spark plug connectors 303-622 (21-226) |

General equipment:

- Probe set

- Micrometer

- Sleeve (8x12mm) or suitable washers

| Name | Specification |

| clamps | |

| Silicone grease for spark plug connector seals | A960-M1C171-AA |

Adjustment

1.

CAUTION: To adjust valve clearance, replace shims (shims).

Disconnect the ground wire from the battery. See Section 414-01 for more information.

2.

NOTE: Do not remove the timing belt top cover.

Loosen the bolts in the upper timing belt cover.

3.

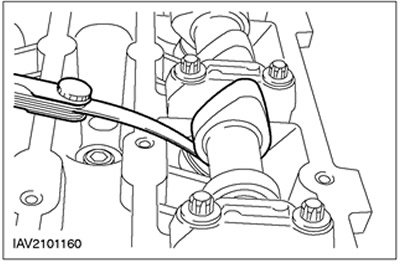

CAUTION: When disconnecting the spark plug connector, do not pull on the wire. If necessary, disconnect the ignition wires from the ignition coil to avoid twisting the ignition wires. Before disconnecting the spark plug connector, turn it slightly to loosen the seal.

CAUTION: When disconnecting the spark plug connector, keep it aligned with the spark plug.

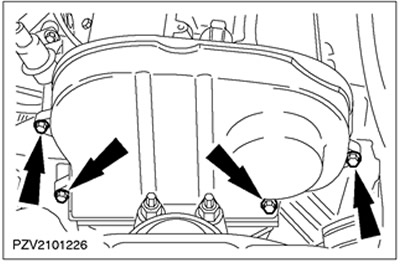

NOTE: Release sequence: from outside to inside, working in a cross way.

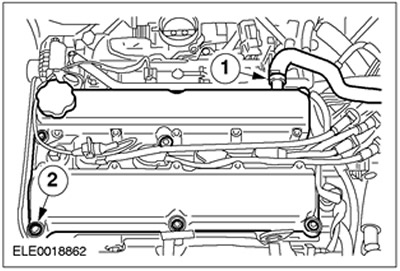

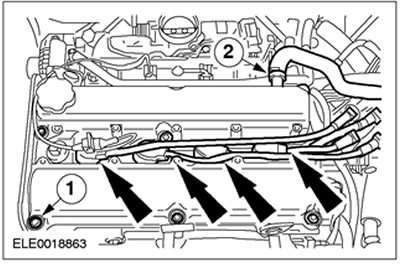

Remove the cylinder head cover.

- Disconnect the spark plug connectors.

- 1.Disconnect the crankcase ventilation hose.

- 2. Remove ten bolts.

4.

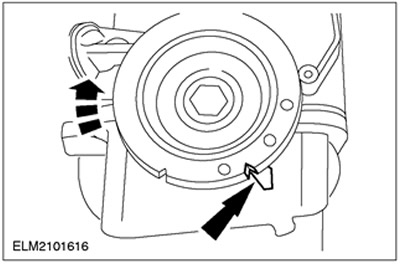

CAUTION: Only turn the engine through the crankshaft and in the direction of its normal rotation.

Set the engine to top dead center for cylinder #1.

5.

NOTE: Record each cylinder number and measured valve clearance.

Measure the valve clearance using a feeler gauge set.

- Allowable valve clearance: Inlet valve (0.11 - 0.18 mm)

- Allowable valve clearance: Exhaust valve (0.27 - 0.34 mm)

- Rotate the crankshaft further in successive steps of 180 degrees each time and check the valve clearances in the remaining cylinders. In this case, the measurement sequence corresponds to the ignition order: 1-3-4-2

6.

NOTE: Follow the steps below only if valve clearance needs to be adjusted.

Connect the special tool.

7.

NOTE: Aim for a valve clearance that is in the middle of the allowable range (intake valves - 0.15 mm; exhaust valves - 0.30 mm)

NOTE: The shim number indicates the thickness of the shim. Example: 222 = 2.22 mm.

Determine the required gasket thickness.

- Remove the shim from the pusher and find out the thickness by the number stamped on the back (if it is not clear, measure the gasket thickness using a micrometer).

- Determine the required shim thickness and insert the shim.

- Intake valves: thickness of gasket to be installed = thickness of gasket present + measured valve clearance - 0.15 mm.

- Exhaust valves: gasket thickness to be installed = existing gasket thickness + measured valve clearance - 0.30 mm.

8. Replace shims.

9. Disconnect the special tool.

10. After completing the adjustment, recheck the valve clearances.

11.

CAUTION: To avoid damage to the spark plug connector seal, use a blunt object to apply silicone grease (e.g. plastic clamp).

CAUTION: When mating the spark plug connector, keep it in line with the spark plug.

NOTE: Coat the inside of the spark plug connector with silicone grease to a depth of (5-10) mm.

Install the cylinder head cover.

- 1.Install ten bolts and tighten them in two steps.

- Stage 1: 2 Nm

- Stage 2: 7 Nm

- 2.Install the crankcase ventilation hose.

- Match the spark plug connectors so that they snap into position.

12.

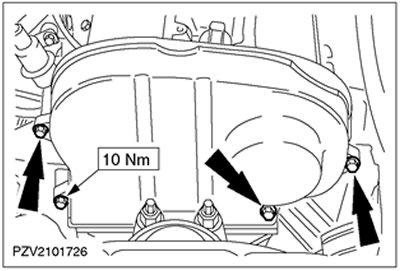

NOTE: Check that the gasket on the top cover of the timing belt is correctly installed and adjust if necessary.

Install the timing belt top cover.

13. Connect a wire of weight to the accumulator. See Section 414-01 for more information.

14. Check fluid levels and adjust if necessary.

15. Check if the vacuum hoses, cables and cables are properly separated and fix them in the required position using the clamps.

Visitor comments