Perform work on a viewing ditch, overpass or lift.

You will need: socket heads «on 10», «at 13», studs M8 (5 pieces.) at least 20 mm long.

1. Drain engine oil (cm. «Changing engine oil and oil filter»).

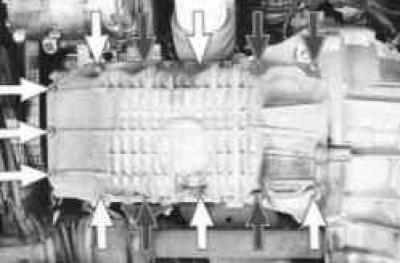

2. Turn out four bolts of fastening of a transmission to an oil case.

3. Turn out thirteen bolts of fastening of an oil case to the block of cylinders of the engine, accurately pry off a screw-driver and remove an oil case. Blind holes in the cylinder block for bolts, shown by red arrows, must be protected from sealant. To do this, screw five M8 studs into the cylinder block.

4. Clean the mating surfaces of the oil crankcase and cylinder block from the old sealant.

5. Apply a special gasket sealant to the mating surface of the oil sump (FORD WSE-M4G323-A4 or equivalent) in the form of a roller with a diameter of 3–4 mm, and the line for applying the sealant-gasket should pass from the inside of the mounting holes.

6. Not later than 10 minutes after applying the sealant, install the oil crankcase on the cylinder block, unscrew the studs and screw in, without tightening, the crankcase mounting bolts.

WARNING: To ensure seal tightness, the next two steps must be completed within 5 minutes after crankcase installation.

7. Screw in the four bolts securing the gearbox to the oil sump and tighten them to a torque of 47.0 Nm (4.7 kgf·m).

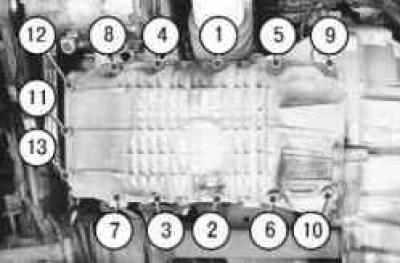

8. Tighten the crankcase mounting bolts in the order shown in two steps:

Stage I - pre-tightening with a torque of 10.0 Nm (1.0 kgf·m);

Stage II - final tightening with a torque of 20.0 Nm (2.0 kgf·m).

9. Fill engine oil (cm. «Changing engine oil and oil filter»).

NOTE: You can fill in oil and start the engine no earlier than one hour after installing the oil sump: this time is necessary for the polymerization of the sealant.

Visitor comments