Manual Transmission made according to a two-shaft scheme with five (at the MMT6 gearbox - with six) synchronized forward gears. Gearbox and main gear with differential have a common crankcase 2 (pic. 6.4 and 6.5). Clutch housing 6 is attached to the front of the gearbox housing (see fig. 6.4) and 5 (see fig. 6.5). A stamped steel cover is installed on the rear of the gearbox housing 1

(see fig. 6.4 and 6.5).

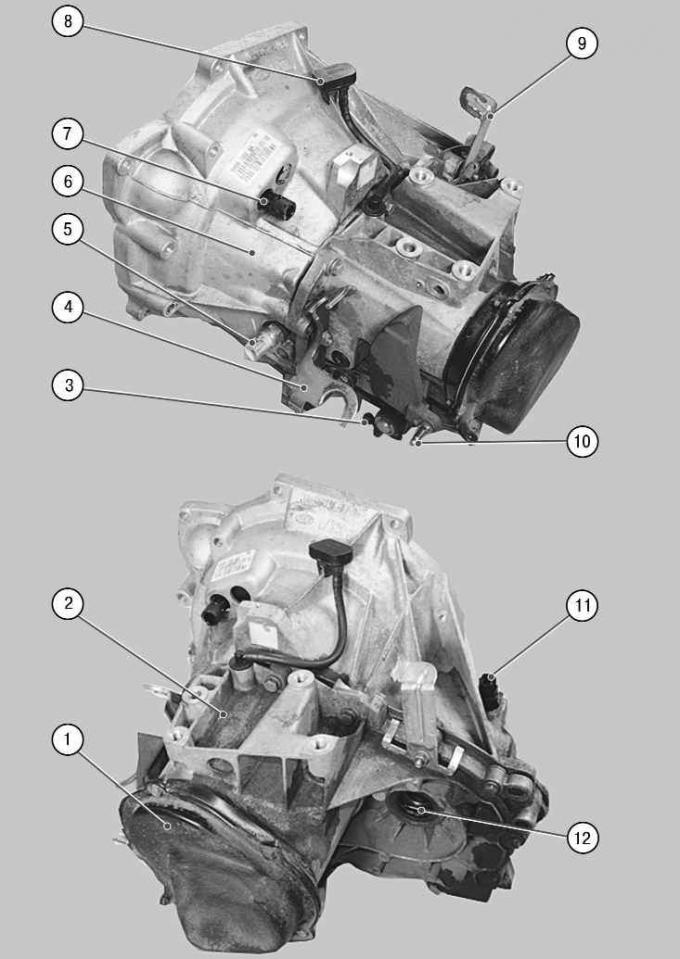

Pic. 6.4. Manual Transmission (shift cover removed for clarity): 1 - gearbox housing cover; 2 - gearbox housing; 3 - gear selection lever; 4 – an arm of fastening of cables of management by a transmission; 5 - reverse light switch; 6 - clutch housing; 7 - adapter of the working cylinder of the clutch release drive; 8 - breather; 9 – an arm of fastening of the pipeline of a hydrodrive of deenergizing of coupling; 10 - gear lever; 11 – speed sensor; 12 - axle shaft seal

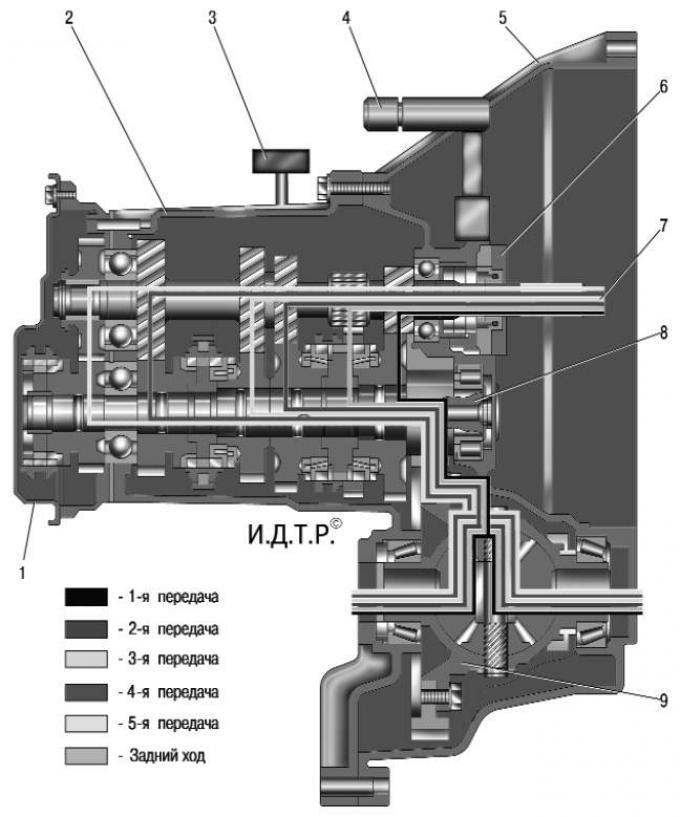

Pic. 6.5. Schematic diagram of a five-speed manual gearbox: 1 - rear cover of the gearbox housing; 2 - gearbox housing; 3 - breather; 4 - the working cylinder of the clutch release hydraulic drive; 5 - clutch housing; 6 - clutch release bearing; 7 - input shaft; 8 - secondary shaft; 9 - main gear and differential

On input shaft 7 (see fig. 6.5) there is a gear of the 5th gear fixed on the splines of the shaft with a synchronizer, and the drive gears of the 1st, 2nd, 3rd and 4th gears are made in one piece with the input shaft.

The secondary shaft 8 is made together with the drive gear of the final drive 9. In addition, the driven gears of I, II, III, IV and V gears freely rotating on plain bearings are installed on the shaft.

The forward gears are switched on by axial movement of the clutches of two synchronizers of I–II and III–IV gears and the synchronizer clutch of the V gear mounted on the secondary shaft. The gearshift mechanism is located inside the gearbox housing on its left side. Outside there are two levers of the mechanism: lever 3 (see fig. 6.4) gear selection and shift lever 10.

The manual transmission control drive consists of a gear lever link with a ball bearing mounted on the base of the body, two shift and gear selection cables, as well as a mechanism installed in the gearbox housing. To ensure a clear gear shift, the shift lever 10 of the shift mechanism is made in one piece with a massive counterweight. The gear selection and shift cables are structurally different from each other and are not interchangeable.

The main gear is made in the form of a pair of cylindrical gears matched according to noise. Torque is transmitted from the driven gear of the final drive to the differential and then to the front wheel drives.

The differential is conical, two-satellite. The tightness of the connection of the internal hinges of the front wheel drives with the differential gears is ensured by seals 12.

The automatic transmission with adaptive control system provides the optimal shifting mode for almost any driving style and road conditions. Automatic transmissions installed with engines with a working volume of 1.6 and 2.0 liters are the same in design and differ only in gear ratios.

Automatic transmission arranged according to the traditional planetary circuit with friction braking and connected to the engine crankshaft through a torque converter. A feature of the Ford Focus II gearbox compared to previous generations of automatic transmissions is the ability to switch from fully automatic control mode to manual mode (so-called sequential gearbox), in which the driver, during the acceleration of the car, independently chooses the moment of switching to overdrive. This allows, if desired, more intense acceleration than automatic mode, artificially delaying the upshift, which allows you to bring the engine speed to the maximum torque range. At the same time, the electronic control system constantly monitors the vehicle speed and engine load, eliminates driver error by not allowing him to shift into a higher gear at low speed in order to avoid overloading the engine, and also does not allow downshifting at too high a speed, which eliminates the possibility of exceeding the maximum permissible engine speed. When the vehicle speed decreases, the gears automatically switch to lower gears without the participation of the driver. When the car comes to a complete stop, 1st gear is automatically engaged.

The automatic transmission control drive is cable-operated, designed on the same principle as the manual transmission control drive, but differs from it in the number and design of parts. The automatic transmission selector is installed in the same place on the floor tunnel as the manual transmission control lever, and is connected to the control unit on the gearbox by a control cable.

The differential of an automatic transmission is completely similar in design to the differential of a manual transmission.

To repair a gearbox, especially an automatic gearbox, a large set of special tools and appropriate training of the performer are required, therefore, this section discusses only the removal and installation of the gearbox, replacing its seals, and repairing the drive. If necessary, have the gearbox repaired at a specialized service.

Visitor comments