Warning: Brake fluid is dangerous. If it comes in contact with your skin, wash it off immediately and if it gets into your eyes, seek medical attention. Brake fluid damages paintwork and plastics. If liquid comes into contact with such surfaces, immediately wash it off with plenty of clean water.

Withdrawal

1. Create a vacuum in the servo by depressing the brake pedal several times (engine not running).

2. On automatic transmission models, remove the transmission fluid level dipstick to improve access.

3. Disconnect the wiring harness connector for the low brake fluid level indicator. This electrical connector is installed on the lid of the reserve tank (see fig. 11.3). Unscrew and remove the cover.

4. Pump out liquid from a tank by means of a tube.

Warning: Do not suck liquid through the tube with your mouth, it is dangerous. If brake fluid gets on the paintwork, it must be washed off immediately with clean water.

5. On hydraulic clutch models, loosen the hose clamp and disconnect it from the reservoir (see fig. 11.5). Plug the hose to prevent dirt from entering it.

6. Determine the location of the pipeline for each brake on the master cylinder. Non-ABS models have four pipes. The two rear brake lines are connected to pressure limiting valves mounted on the master cylinder. On models equipped with ABS, the master cylinder has only two lines connecting it to the ABS hydraulic modulator (see fig. 11.6).

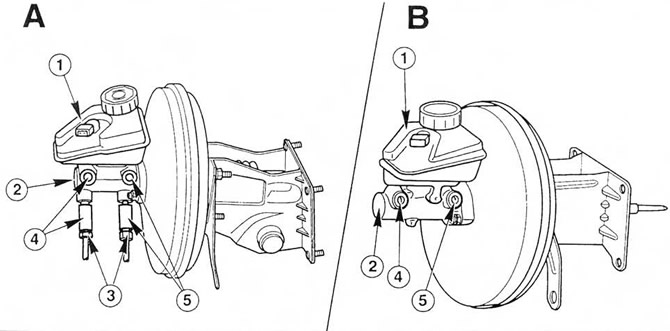

Pic. 11.6. Master cylinder connections (A - models without ABS, B - models with ABS).

Pic. 11.6. Master cylinder connections (A - models without ABS, B - models with ABS).

1. Reserve tank

2. Master cylinder

3. Pressure limiting valves for rear brakes

4. Primary circuit of the brake hydraulic system (front right/rear left brake)

5. Secondary circuit of the brake hydraulic system (front left / rear right brake)

7. Cover the master cylinder with rags to catch smudges.

8. Wipe the union nuts. Turn away nuts and disconnect pipelines from the main cylinder.

9. Turn away nuts of fastening of the cylinder and remove the cylinder from hairpins established in a forward part of the brake booster. If the nuts are difficult to loosen, use a box wrench instead of a regular wrench. Plug or cover the resulting openings to prevent dust or dirt from getting in.

10. Remove the gasket from the master cylinder.

11. If the master cylinder is defective, it must be replaced. At the time this manual was written, no repair kits were available for this manual.

Installation

12. Clean the interface between the master cylinder and the servo. Install a new gasket on the master cylinder.

13. Install the master cylinder on the servo studs. Install and tighten the nuts to the required torque.

14. Carefully insert the lines into the holes in the master cylinder, and then tighten the nuts. Make sure that the nuts fit the threads without distortion.

15. Install the clutch hydraulic hose (in the presence of).

16. Remove air from the hydraulic brake system (paragraph 15) and clutch (in the presence of) (paragraph 6).

17. Establish a tank cover and connect an electrosocket of the indicator of low level of a brake liquid.

18. On models with automatic transmission, install the transmission fluid level probe.

19. Before resuming travel by car, carefully check the brakes.

Visitor comments