Note: see warning at the beginning paragraph 15 about careful handling of brake fluid.

1. Raise the front and rear of the car and place supports under them.

2. Inspect piping connections for leaks. Inspect the hoses for cracks and fraying.

3. Inspect the brake lines for corrosion, dents, or other damage. Traces of corrosion can be removed. scraping the pipe, but if there is significant pitting, the pipe must be replaced. Such defects are especially likely on pipelines passing under the bottom.

4. Replace defective lines and/or hoses.

Withdrawal

5. If you need to remove a section of tubing or hose, the leaks must first be minimized. Place a thin film under the reservoir cap and tighten the cap. Instead, you can pump out the fluid from the tank (paragraph 11).

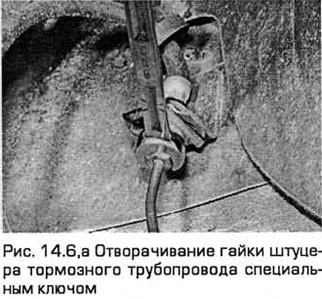

6. To remove the tubing section, unscrew the nipple nut from the tubing side. At the same time, hold the nut of the fitting connected to the hose pipeline with a wrench from turning. Pull out the pipeline. Loosen the nut on the other pipe in the same way. Then release the pipe from the clamps connecting it to the bottom, and remove the pipe (see fig. 14.6, a, b).

7. Some nuts are difficult to loosen, especially in open areas subject to dampness. Therefore, to unscrew them, it is better to use a special wrench for brake pipe nuts, covering all planes of the nut. If you do not have such a key, then you can use self-tightening forceps.

8. To minimize fluid leakage when disconnecting the flexible hose from the pipe, pinch the hose as close to the pipe as possible with a brake hose clamp.

9. To remove the flexible hose, first clean the ends of the hose and nearby surfaces. Then unscrew the union nuts at the ends of the hose. Remove the elastic retainer and pull the hose out of the barbed support in the support bracket. Where necessary, separate the hose from the caliper.

10. Brake lines have flared ends and nuts. These pipes can be purchased individually or as a set. After that, the pipe must be bent, using the old pipe as a sample.

Installation

11. Installation - in the reverse order of removal. Make sure all piping is secure and hoses are not kinked. Check that the hoses must run clear of all suspension components and bottom mountings.

12. Finally, remove air from the hydraulic system (paragraph 15).

Visitor comments