Warning: Before disassembling the rack, prepare the coil spring compressor. Do not use improvised tools as this may cause the spring to pop out and cause injury. After removing the spring with the tool, leave it in the tool in a safe, closed place.

1. If there are signs of suspension strut wear such as leaks, insufficient damping, settling or spring cracks, the strut should be disassembled and repaired. In this case, the shock absorber assembly in the event of a malfunction must be replaced as a whole, since it cannot be repaired. Springs and related components can be replaced. To ensure reliable damping, components on both sides of the vehicle must be replaced at the same time.

2. After removing the rack from the car, clean the dirt from it and install it in a vise.

3. Install the spring compressors and compress the spring so that the upper support does not take its force (see fig. 5.3).

4. While holding the piston with a hex wrench, loosen the thrust bearing nut with a spanner wrench (see fig.5.4).

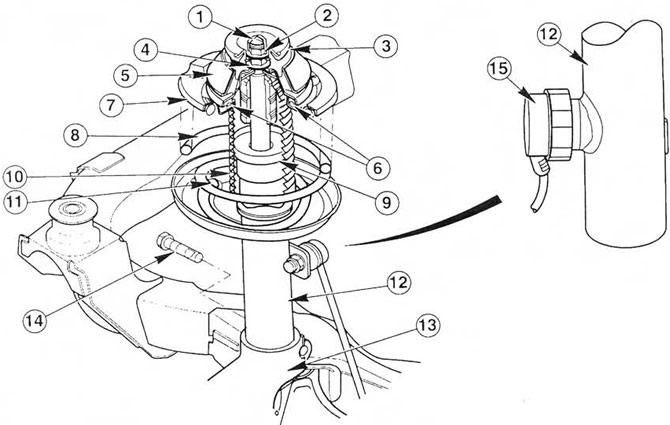

5. Remove the top support, thrust bearing, top spring seat and spring, then boot and bump stop (see fig. 5.5, a-g).

Pic. 5.5, a. Front suspension strut components.

Pic. 5.5, a. Front suspension strut components.

1. Cap

2. Nut

3. Stopper

4. Nut

5. Upper support

6. Thrust bearing

7. Upper spring seat

8. Spring

9. Chipper

10. Case

11. Lower spring seat

12. Rack

13. Knuckle

14. Clamp bolt

15. Solenoid valve adaptive suspension

6. If you will install a new spring, then unclench the fixture and remove the spring from it. If you install the same spring, you can leave it in the fixture.

7. Now that the rack has been disassembled, inspect all components for wear and damage. Check the bearing - it should rotate evenly. Replace components if necessary.

8. Inspect the rack for leaks. Inspect the piston rod for pitting along its entire length. Inspect the rack housing for damage.

9. Check how the rack works. Keeping it upright, move the piston from stop to stop, and then back and forth by 50-100 mm. In both cases, you should feel a uniform and constant resistance to the movement of the piston. If you feel jerky or uneven resistance, or notice wear or damage to the strut, it should be replaced.

10. Reassemble in the reverse order of disassembly, taking into account the following:

- A) Before releasing the spring compressor, push the top and bottom ends of the spring into its top and bottom seats.

- b) Install the bearing correctly in its seat on the piston rod.

- V) Tighten the thrust bearing nut to the specified torque.

Visitor comments