Note: Do not attempt to remove these seals unless you have removed the oil pump or seal housing. because they are too soft, and access to them is limited. In order not to damage the cuff housing and / or the crankshaft journal, follow the instructions below.

Right cuff

1. Remove the oil pump (paragraph 17).

2. Remove the cuff from the back of the pump (see fig. 21.2).

3. Clean the oil seal housing and crankshaft, removing any burrs or sharp edges that could damage the oil seal.

4. Install the oil pump (paragraph 17). Lubricate the edges of the new cuff.

5. It is recommended to use a tool to fit the cuff in place (Ford 21-093A) together with the crankshaft pulley bolt. Another option is to take a bushing of the right size, as well as a washer and a crankshaft pulley bolt (see fig. 21.5).

6. If you do not have such tools at hand, press the cuff into place with your hand. Drive the collar flush with the pump housing using a soft-faced hammer and a bushing slightly smaller than the collar to be supported on its outer diameter (see fig. 21.6). Be careful not to skew the cuff and do not damage it.

7. Wash off any remaining oil. The remaining operations are in the reverse order of removal. Immediately after starting the engine, check for oil leaks.

Left cuff

8. Remove the transmission (relevant part of Chapter 7).

9. Where necessary, remove the clutch (chapter 8).

10. Remove the flywheel/faceplate bolts (paragraph 22).

11. Remove the pallet (paragraph 16).

12. Turn out bolts of the case of a cuff (see fig. 21.12). Remove and discard the gasket.

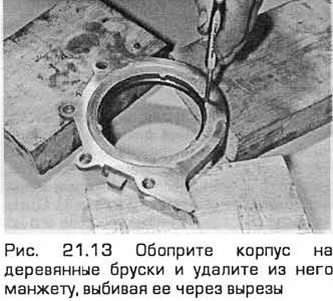

13. Lean the body on wooden blocks and knock out the cuff from the back of it (see fig. 21.13).

14. Clean the seal housing and crankshaft of burrs and sharp edges that could cause seal failure. Also clean the cylinder block/crankcase and seal housing mating surfaces with a scraper to remove any old gasket residue. Do not scratch or damage the material to be cleaned. After cleaning, these surfaces must be degreased with a solvent.

15. Use grease to stick a new gasket on the cylinder block/crankcase. Then bring the cuff body to the installation site (see fig. 21.15).

16. Using a ruler and feeler gauges, make sure. that the housing is precisely centered on the crankshaft and installed without distortion so that its interface is below (at a distance of 0.3...0.8 mm) cylinder block/crankcase interface. This distance must be the same on each side of the crankshaft. Without displacing the gasket, move the housing to the required position and tighten its bolts to the required torque (see fig. 21.16).

17. Make sure. that the chassis is installed correctly. If necessary, unscrew its bolts again and repeat the entire procedure to install the housing in the desired position.

18. When installing the cuff, it is recommended to use a tool (Ford 21-141), as well as two flywheel mounting bolts to push the collar into place. Another option is to make a guide out of thin plastic or something similar. After that, lubricate the lips of the new seal and the crankshaft shoulder with grease and insert the seal over the plastic guide onto the crankshaft shoulder (see fig. 21.18). Push the seal evenly into the housing by hand. Use a soft-faced hammer to drive the collar flush with the body.

19. Wipe off any remaining oil or grease. The remaining operations are performed in the reverse order of removal. After starting the engine, check for oil leaks.

Visitor comments