2. Turn out bolts of covers of radical bearings (4 cylinder engines) or lower crankcase (V-shaped 6-cylinder engines). Remove covers (and fold them in the appropriate order for proper installation) or lower crankcase.

3. Remove the old liners from the block and caps of the main bearings or the lower section of the crankcase. Clean the block bearing cradles and covers with a clean, lint-free cloth. They need to be kept perfectly clean!

Checking the working clearance of main bearings

4. Clear new loose leaves of radical bearings from the back party. Install the oil groove bushings in their positions in the cylinder block. Please note that on 4-cylinder engines, thrust washers are made in one piece with the upper main bearing shell No. 3 (central). On V-shaped 6-cylinder engines, the thrust washer in the form of a half ring adjoins the end face of the upper shell of the main bearing No. 4. Install another bushing from each set into the corresponding main bearing cap (4 cylinder engines) or in the lower crankcase (V-shaped 6-cylinder engines). Make sure that the protrusion of each bushing fits into the notch of the block or cover. Note also that the oil passages in the block must align with the oil passages of the bushings (see fig. 18.4).

Caution: Do not hammer bushings into place and do not scratch bearing surfaces. Do not apply lubricant at this stage.

5. Clean the working surfaces of the liners installed in the block, as well as the crankshaft main journals with a clean, lint-free cloth. Check or flush the oil passages in the crankshaft as any dirt will pass through the new liners.

6. A clean crankshaft must be carefully installed in its place in the main bearings. Cut off a few pieces from the plastic clearance gauge of the appropriate size - the cut pieces should be slightly shorter than the width of the main bearings. Install one piece on each main journal of the crankshaft parallel to its axis (see fig. 18.6).

7. Clean the working surfaces of the liners installed in the covers (4 cylinder engines) or lower crankcase (V-shaped 6-cylinder engines). Install the covers in the correct position. (Don't confuse them). The arrows on the covers must point towards the toothed belt. Do not mix pieces of the plastic template (see fig. 18.7).

8. On 4-cylinder engines, alternately servicing the covers and starting at the central main bearing, and then continuing towards the ends of the crankshaft, (evenly and without distortion) tighten bolts of covers of radical bearings the demanded moment. Do not rotate the crankshaft while performing this operation! On V6 engines, tighten the lower crankcase bolts (see below).

9. Turn out bolts of covers of radical bearings (lower crankcase) and remove the covers or lower crankcase. Be careful not to damage the measuring thread and do not rotate the crankshaft. If the cover sticks, tap it with a soft-faced hammer.

10. To determine the operating clearance of the main bearings, compare the width of the flattened thread with the template included in the kit (see fig. 18.10). Compare the resulting value with technical requirements.

11. If the gap deviates from the regulated value, contact dealers or engine repair specialists. If the crankshaft journals are normal (see paragraph 13), it is possible that it will be possible to provide the required clearance by replacing the liners. Otherwise, you need to transfer the shaft for regrinding and receive it together with liners of the appropriate repair size. Before deciding to purchase liners of a different size, make sure 8 that there is no dirt or oil between the liners and the bearing bores in the block and in the covers. If the ends of the deformed thread have different widths, then the crankshaft journal has a taper.

12. Finally, carefully scrape off the remaining plastic thread from the crankshaft and bearing shells with a fingernail or plastic scraper so as not to scratch the bearing surfaces.

Final installation

13. Carefully remove the crankshaft. Clean the bearing surfaces of the bearings in the block, and then lubricate them with a thin, even coat of clean molybdenum disulphide grease or clean engine oil (see fig. 18.13). Also lubricate surfaces that receive axial force.

14. Lubricate the crankshaft seal journals with molybdenum disulfide grease or clean engine oil.

15. Make sure that the crankshaft journals are clean, and then lay the shaft in the block (see fig. 18.15). Clean the working surfaces of the liners located in the covers, and then lubricate them. Install the covers in their respective places with the arrows pointing towards the toothed belt.

16. On 4-cylinder engines:

- A) Clean and lubricate the surfaces under the liners in the covers, Install the covers in their original position - arrows in the direction of the toothed belt.

- 6) Servicing the covers one by one, starting from the center and continuing towards the ends of the shaft, tighten their bolts evenly and without distortion to the required torque.

17. On V-shaped 6-cylinder engines:

- A) Apply a 3.0 mm bead of sealant (see fig. 18.17, a).

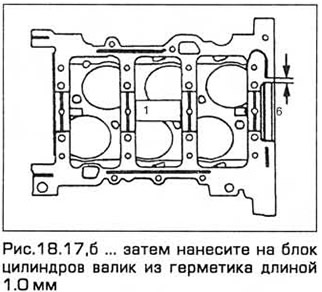

- b) Apply a 1.0 mm bead of sealant (see fig. 18.17.6).

- V) Insert the lower crankcase bolts. Tighten the bolts to the required torque.

18. Rotate the crankshaft a few revolutions, making sure there is no binding.

19. Check shaft end play (see paragraph 11). It should be normal if the bearing surfaces of the shaft are not worn or damaged, and also provided that the liners that perceive the axial force are replaced.

20. On 4-cylinder engines, install the housing of the left crankshaft cuff, and then insert a new cuff (chapter 2A paragraph 20).

21. On V-shaped 6-cylinder engines, install a new cuff (chapter 2B).

Visitor comments