Note: Before starting this procedure, you should already have spare brushes. At the time of writing this manual, generator components are not available separately as spare parts. At the same time, spare parts such as brushes can be purchased from auto electricians.

Note: The procedure below is for the Lucas/Magneti Marelli starter. For a Bosch starter, the procedure is similar.

1. Remove the starter (paragraph 9) (see fig.10.1).

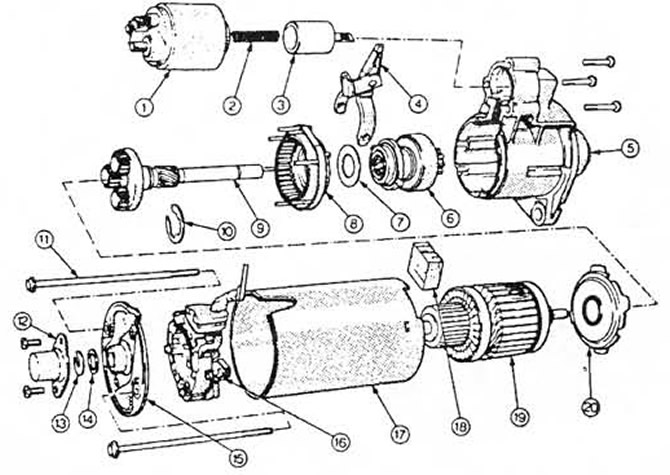

Pic. 10.1. Starter Bosch DW (parted view)

Pic. 10.1. Starter Bosch DW (parted view)

1. Solenoid

2. Spring

3. Plunger

4. Switch lever

5. Drive End Cap

6. Drive gear and clutch

7. Distance washer

8. Housing and gear with internal teeth

9. Output shaft with planetary gear assembly

10. Elastic ring

11. Screw

12. End cap

13. Retaining ring

14. Adjusting washer

15. Manifold housing

16. Brush holder

17. Clip

18. Rotor

20 Stop disc

Brush replacement

2. Remove the brushes (see fig. 17.2, a-i).

3. Sometimes the brushes have a mark corresponding to the wear limit, in the form of a groove, which is etched and located along the front surface of the brush. When the brushes are worn down to these marks, they need to be replaced. If the marks on the brushes are not provided, then you need to measure the height of each brush and compare the readings with the regulated value. If any of the brushes are worn to the limit, then the entire set of brushes must be replaced. If the brushes can be used, wipe them with a cloth soaked in gasoline. Make sure that the brushes are securely and with the same force pressed by the springs to the commutator. If you are in doubt about the condition of the brushes and springs, compare them with new components.

4. Clean the collector with a cloth dampened with gasoline. Then check it for scoring, burning, excessive or pitting wear. If wear or damage is found, the manifold must be shown to an auto electrician.

5. Installation - in the reverse order of removal.

Solenoid Replacement

6. Loosen the nut, paying attention to the lock washer (s). Disconnect the motor bus from the solenoid terminal.

7. Turn out two bolts of fastening of the solenoid to an end cover of the electric motor.

8. Release the solenoid plunger from the starter engagement lever. Then remove the solenoid, paying attention to the springs.

9. Installation - in the reverse order of removal. Thoroughly clean the solenoid, its plunger, and the motor/solenoid mating surfaces. Lubricate plunger/starter lever with grease.

Visitor comments