- MkPherson shock absorber struts with coil springs, which are installed between two suspension support cups;

- double-acting hydraulic shock absorbers;

- triangular wishbones.

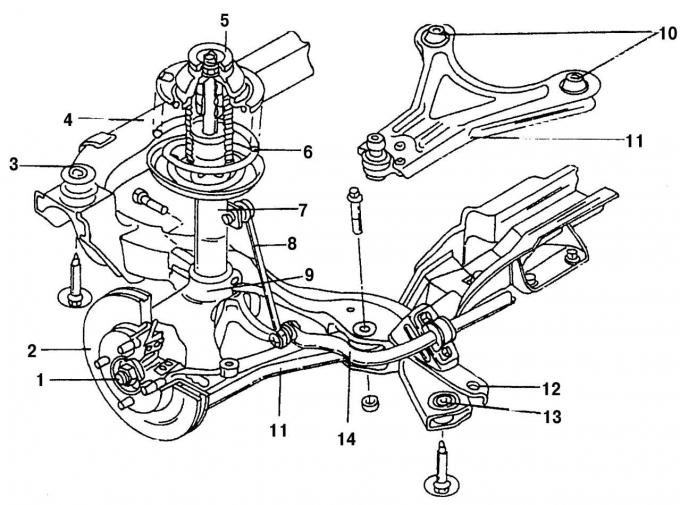

Pic. 185. Front suspension assembly: 1 - wheel drive shaft nut; 2 - brake disc; 3 - front rubber bushing; 4 - subframe; 5 — the top bearing of a shock-absorber rack; 6 - twisted spring; 7 - shock absorber; 8 — thrust anti-roll bar; 9 - knuckle; 10 - rubber-metal bearing; 11 - transverse lever; 12 - guide hole for leveling the subframe (at both sides); 13 - rear rubber bushing; 14 - anti-roll bar

The anti-roll bar is attached to the subframe and is connected to the upper parts of the shock absorber struts by means of a system of rods and levers on the left and right. The steering knuckles are attached to the transverse levers. For this, two nuts and two bolts are used, tightened through vertically arranged bushings. On the underside of the steering knuckle is a replaceable ball joint, which is designed to connect the transverse arm to the steering knuckle. On fig. 185 shows the front suspension, which most models are equipped with. Model with 200 hp engine. differs in the design of the transverse lever, which is shown in Fig. 186.

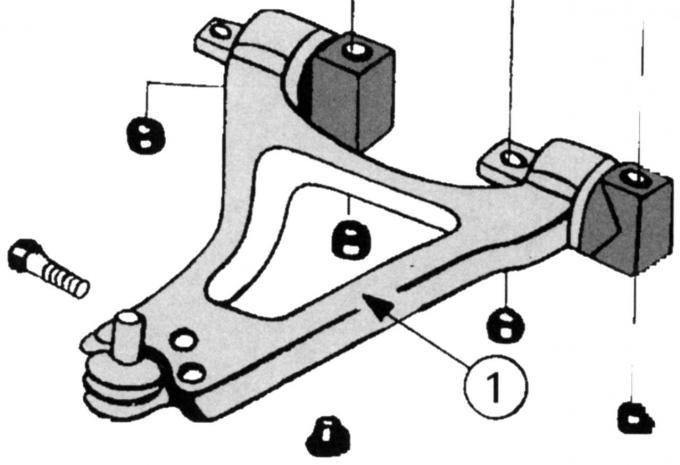

Pic. 186. Wishbone on a car with a V6 engine (200 HP)

The shock strut consists of a coil spring and a telescopic shock absorber that is inserted into the spring. The internal stops of the shock absorber strut limit the amount of reverse travel. In case of severe elastic deformations, for example, when hitting a pothole on the road, a similar thrust limiter comes into action. The shock absorber struts are held on top by support elements attached to the body. The rack is protected by a cuff to prevent dirt from getting in. The rubber buffer of the shock absorber strut prevents breakdown of the wheel suspension in a compressed state.

The shock absorber is supported (in the engine compartment). From above it is made in the form of a rubber support (pillows), which, introduced through the centering ring, rests on top and bottom of the disc discs. The shock absorber piston rod is screwed into the rubber support. By means of a nut, the support is attached to the body.

Rounded fist (like a hub) holds the lower end of the rack with a clamp bolt. The steering knuckle is connected to the transverse lever by a ball joint. The trunnion of the latter is firmly clamped in the transverse arm. The transverse lever enters the bearing beam of the bridge, can move in it and takes on the resulting lateral forces. In addition, the steering knuckle is also designed to attach the shock absorber strut, as well as the steering knuckle arm to the tie rod end.

The transverse stabilizer, or anti-roll bar, is attracted to the bottom of the vehicle by rubber bushings and by means of a connecting rod (connecting rod) left and right connected to the shock absorber struts. It reduces lateral lean when cornering.

The rack and pinion steering is located behind the engine and is attached to the transverse frame. Tie rods are attached to the gear rack on the left and right. If the steering wheel is rotated, which is connected to the steering mechanism by means of a two-link steering shaft, this movement is transmitted to the steering knuckle lever and, consequently, to the wheels.

Most suspension repairs require a special tool. If you do not have such a tool or you are not completely sure that you can carry out repairs yourself, contact a specialized service station.

Visitor comments