In general, removal and installation on all models under consideration are carried out in the same way. Some features of the repair of certain models are given below.

Remove the steering gear as follows:

- disconnect «mass» wire in compliance with the necessary security measures;

- set the steered wheels to the straight ahead position;

- disconnect the nut and bolt of the steering shaft coupling from the gear in the engine compartment, to do this, unscrew the bolt and move the pressure plate to the side;

- carefully loosen the seal on the body (do not damage its working edges), to do this, release the fastening clips on the back side, the clip on the upper side, grab the seal from below and fold it up;

- find the clamping bolt of the steering friction clutch on the gear and unscrew the bolt with a suitable wrench, remove the clutch from the back of the car from the gear;

- loosen the wheel nuts, raise the front of the car and set it on reliable supports or place the car on a viewing ditch or overpass;

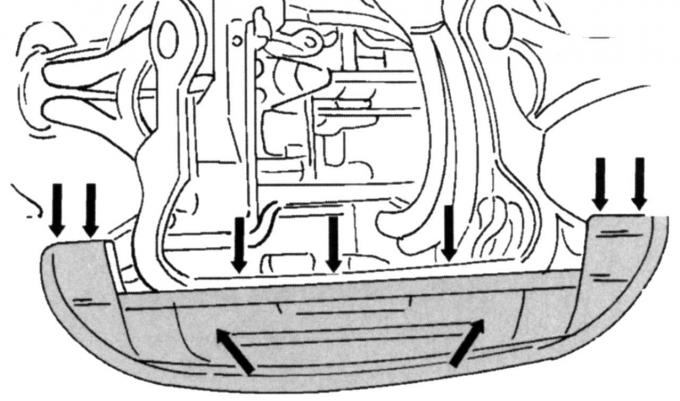

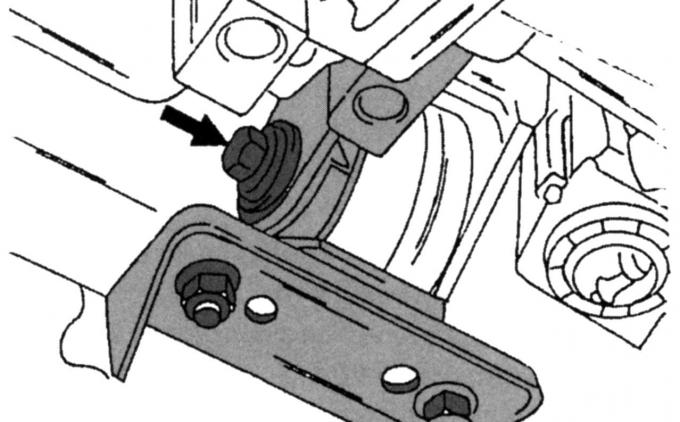

Pic. 232. Fastening the front wall to the rear side of the radiator

- remove the crankcase protection (if it is installed) and the front wall under the radiator (its attachment points are shown in Fig. 232);

- Disconnect the radiator hose of the cooling system and place the hose in a container underneath to collect the escaping coolant;

- on a car with a 2.5-liter engine, remove the catalytic converter as described in the relevant section;

- unscrew the wheels;

- Remove both facings on the right and left wheel arches (see fig. 232);

- Turn away support of shock-absorbers and shift them aside;

- Remove the front wall of the left wing;

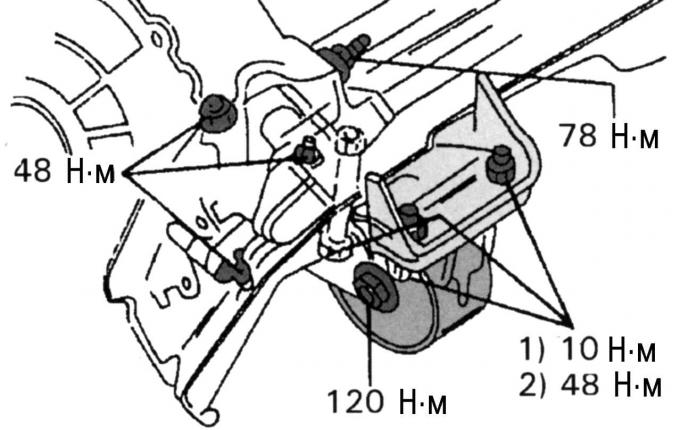

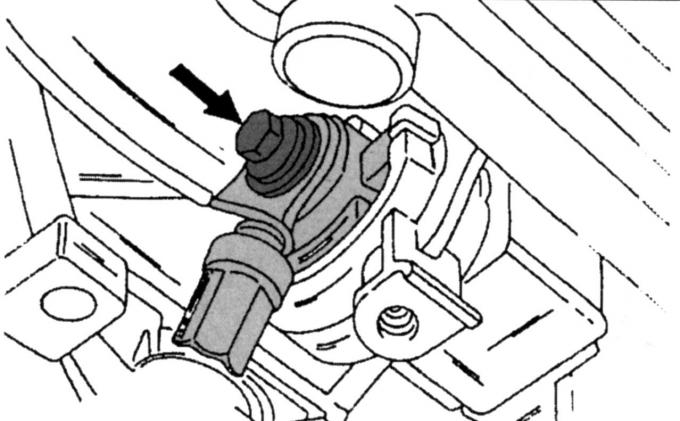

Pic. 233. Fastening the rear stop against turning on a manual transmission

- remove the middle bolt of the rear stop against turning (in fig. 233 and 234 show where this bolt is located in manual and automatic transmissions), for automatic transmission additionally unscrew bolt 1 (pic. 235) in the middle and both nuts 2, and then the suspension bracket and rear rubber stop;

Pic. 234. Fastening the rear stop against turning on an automatic transmission

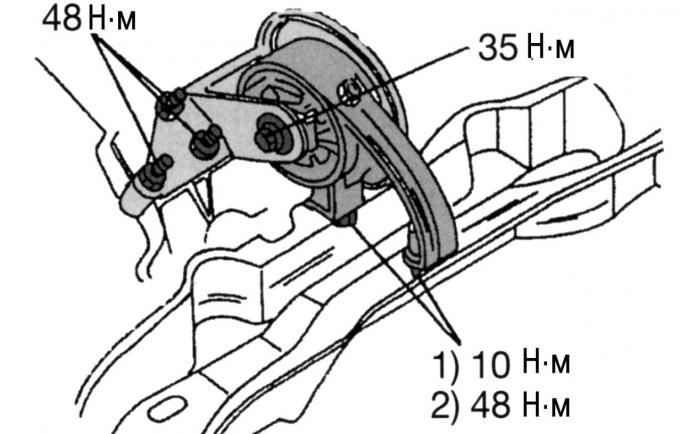

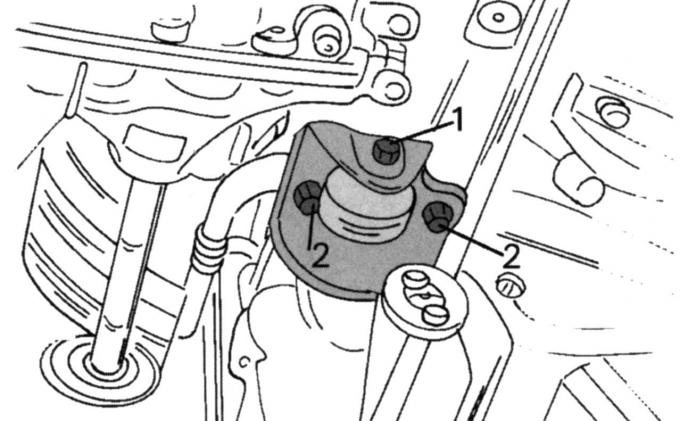

Pic. 235. Suspension bearing (cars with automatic transmission)

Pic. 170. The location of the screw fastening the front stop

- remove the back stop against turning (see fig. 170);

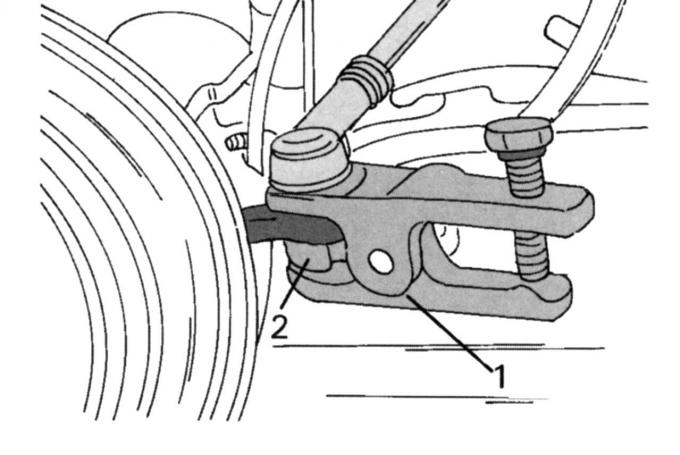

Pic. 236. Tie rod end puller

- unscrew the nut of the tie rod end on the trailing arm and separate the end with a special puller (pic. 236);

- Disconnect the anti-roll bar link on the upper side of the shock absorber (one nut on each side);

- before unscrewing the fastening bolts, mark the position of the subframe and lower its extension onto the jack so that the coolant pipelines can be clearly seen;

- disconnect the captive nuts of the pipelines and remove their double clamps, plug the ends of the pipelines and the holes formed in the steering mechanism to protect them from contamination; collect the escaping liquid;

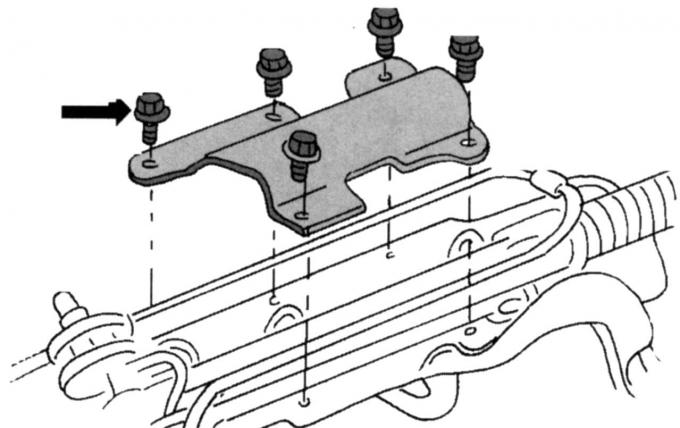

Pic. 237. Protective casing of the steering (only on vehicles with 2.5 liter engine)

- on vehicles with a 2.5-liter engine, unscrew the protective casing of the steering (located in the one shown in Fig. 237 in place and bolted);

- unscrew both steering bolts from the front cross member of the frame, remove the steering mechanism through the wheel arch on the gear side (at the same time, make sure that the check valve does not fall out of its channel);

- if necessary, unscrew the tip of the transverse link after loosening the lock nuts, be sure to record the number of revolutions that it took to unscrew each tip, screw the new tips to the appropriate number of revolutions.

Install the steering in the reverse order of removal, taking into account the following:

- insert the steering gear through the wheel arch and set it in the correct position, tighten both fastening bolts to 137 Nm, pay attention to the significant tightening torque;

- insert new O-rings into the pipe connections (since workshops use tapered bushings for this operation, proceed with extreme caution at this stage), connect the pipeline and tighten the union nuts to 31 Nm, secure the double clamp with both bolts;

- in cars with a 2.5-liter engine, install the protective cover and tighten as shown in fig. 237 bolts with a torque of 50 Nm, tighten the union nuts of the pipelines with a torque of 31 Nm;

- Connect the spherical joints of the transverse steering rods, tighten the nuts to a torque of 37 Nm;

- in cars with a 2.5-liter engine, install a catalytic converter, tighten the flange connection in front and behind with a torque of 40 Nm;

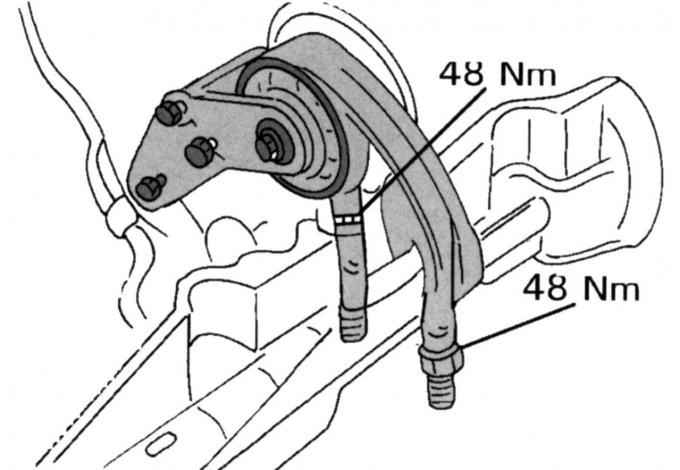

Pic. 238. Rear stop against rotation on an automatic transmission

- in the presence of an automatic transmission establish shown on fig. 238 suspension bearing and tighten to specified torques;

- install the subframe, as described in subsection. «Engine installation», and tighten the four mounting bolts (install it in the position marked before removal);

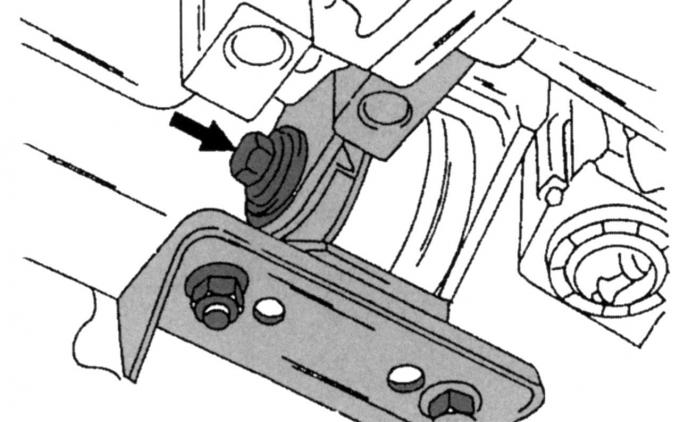

Pic. 239. Fastening the rear stop against turning on the gearbox

- in the presence of an automatic transmission, install the back stop against turning (pic. 239), tighten the bolt to 120 Nm;

- install shown in fig. 235 suspension bearing, tighten bolt 1 to 25 Nm, nuts 2 to 48 Nm;

- in the presence of a manual transmission, tighten the middle bolt of the back stop against turning with a torque of 120 Nm;

Pic. 240. Fastening to the support of the front stop against rotation

- on all vehicles, install the front torque stop and tighten the bolts and nuts to a torque of 120 Nm (pic. 240); if the bolts shown on the underside have been removed, tighten them to 48 Nm;

- fix the connecting rod of the anti-roll bar (50 Nm);

- lower the vehicle to the ground and tighten the wheel nuts to 85 Nm;

- install the steering gear clutch on the gear, insert the bolts and tighten the new bolt with a torque of 19 Nm;

- carefully press the seal of the base of the car body, it must be located exactly in the groove of the steering gear coupling;

- Establish from the inside of the car a pressure plate of a shaft of a column of a steering and tighten a new bolt the moment of 24 Нм;

- connect «mass» wire to the battery;

- fill the steering gear with working fluid and pump it as described in the relevant section;

- Check wheel alignment, adjust if necessary.

Visitor comments