Conversely, complex works are detailed in the text. During any repair work, pay attention to the following:

- screws and nuts must be clean and lightly lubricated. Always check nut surfaces and threads for damage and remove burrs. If in doubt, use new screws and nuts. Used self-locking nuts must always be replaced with new ones. Never degrease nuts and screws;

- always observe the tightening torques of the threaded connections given in the appendix. In most cases, the required tightening torques are given in the description of the repair operations;

- all gaskets, seals, lock washers and rings, cotter pins and O-rings (from a round cord) must be replaced during reassembly. Oil resistant O-rings (radial sealing rings, radial shaft seals) must also be replaced with new ones if the shaft has been removed from the O-ring. One side of the O-ring must be greased before assembly. At the same time, pay attention to the fact that this side, when installing, points in the direction from which oil or grease can come out;

- the left or right side of the car corresponds to the position of the car when it moves forward;

- it is necessary to take measures to create a reliable additional support when working with brakes, wheel suspension, in the lower part of the vehicle mounted on supports;

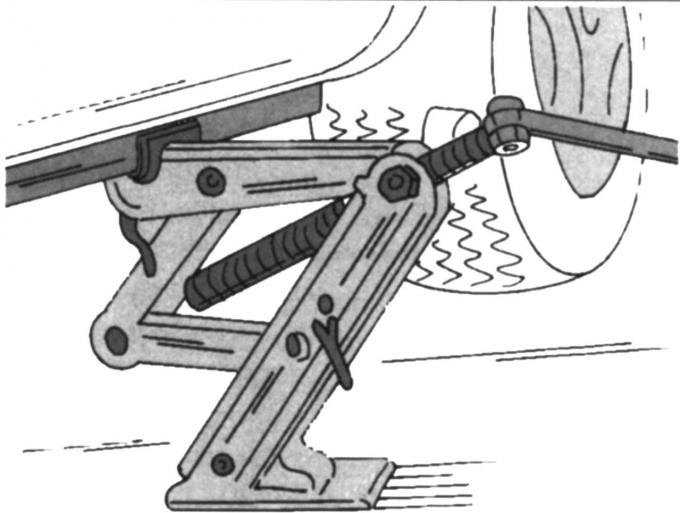

Pic. 6. Car jack in working position

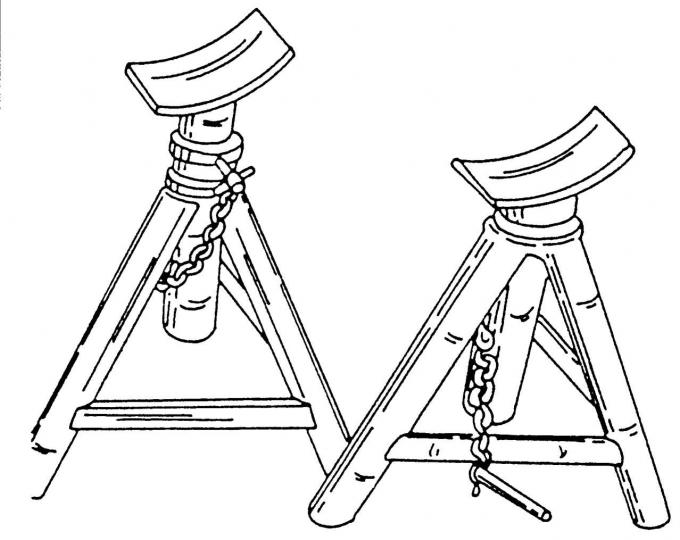

- attached to the car and shown in fig. 6 The car jack is intended only for changing wheels on the road. When repairing, use it as an aid in order to raise the car and then lower it on special supports. In a camper van, a regular car jack looks a little different, but it is used in the same way. tripod supports (pic. 7) placed under the car for greater safety if a garage lift is available. Bricks cannot be used as supports; in extreme cases, use hollow blocks with a large surface. In this case, strong wooden boards must be placed between the car and the blocks;

Pic. 7. Tripods

- Greases, oils, underbody anti-corrosion materials and all mineral substances have an aggressive effect on the rubber parts of the chassis and the brake system. Such products, as well as fuel, must not come into contact with the elements of the hydraulic system. Brake fluid or alcohol must be used to clean the brake system. Do not forget that brake fluid is poisonous and, in addition, corrodes the paintwork of the car;

- to achieve the best repair results, use original spare parts, with the exception of parts for electrical equipment, or authorized by the manufacturer;

- when ordering spare parts, the exact model designation with chassis number, if necessary, the engine number and the year of manufacture must be stated. This will speed up the order and prevent confusion when receiving parts;

- all work, especially with the brake system, steering and wheel suspensions, should be carried out especially carefully - the safety of the car depends on this.

Visitor comments