Pre-clean all cavities and channels. Use a brush and scraper to remove dirt. The cylinders made in the cylinder block are divided during production into size classes, due to the use of prescribed pistons, the required piston clearance is automatically set. In addition to the nominal diameter, the cylinders can be ground to three size classes, which differ for different engines.

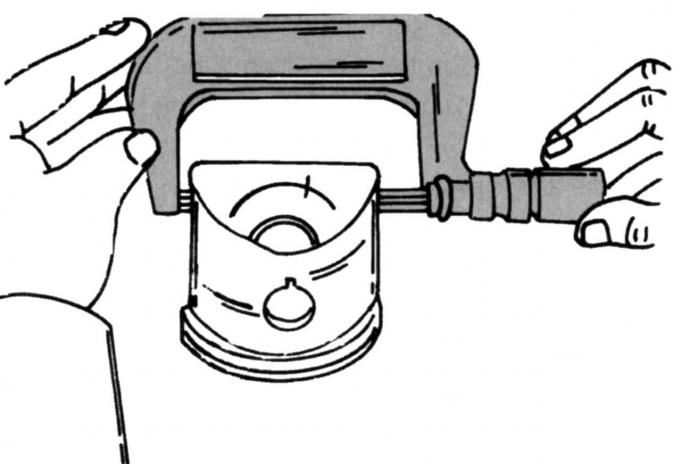

Pic. 81. Measuring the piston diameter at a distance of 42 mm from the bottom

High mileage engines have worn cylinders. In this case, new pistons must be used to obtain the required clearance between the cylinder and the piston. To accurately measure the gap, you will need a dial indicator and a micrometer. Measure the inner diameter of the cylinders with a dial indicator (in several places), and with a micrometer the outer diameter of the pistons, as described in the previous subsection (see fig. 81).

The repair dimensions of the pistons are indicated in the appendix. The holes for the main bearings of the crankshaft can be nominal size or bored to a larger repair size.

All engines are equipped with fixed-size main bearing shells. They are marked with paint.

Visitor comments