To remove the working cylinder, perform the following operations:

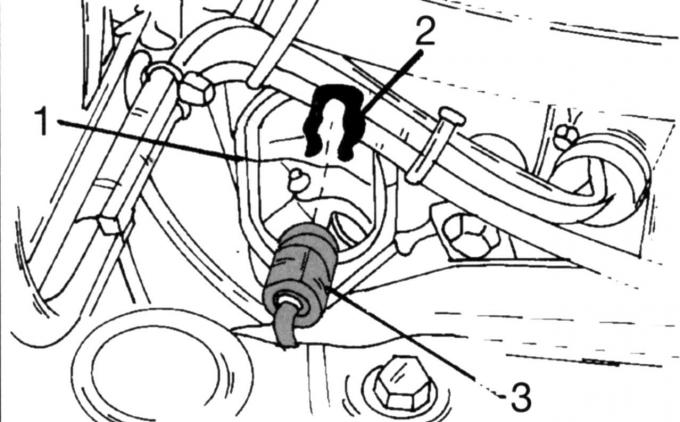

Pic. 152. Shutdown of the liquid pipeline: 1 - dust cap; 2 - safety clamp; 3 - quick-acting constipation

- disconnect the high pressure pipe of the working cylinder (pic. 152). To do this, put on the dust cap, pull up the spring clip, squeeze the quick lock of the wiring and remove the pipeline;

- Remove a transmission, as it is described in subsection. 9.1;

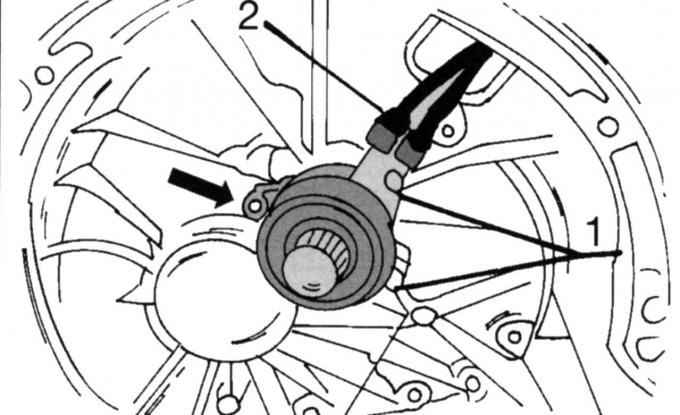

Pic. 153. The location of the fastening of the clutch release bearing: 1 - cylinder screws, 10 Nm; 2 - union nuts, 15 Nm

- unscrew the pipeline 2 (pic. 153) for liquid;

- turn away a carving stopper located nearby for removal of air;

- unscrew screws 1;

- Remove the cylinder with the bearing.

Install in reverse order, taking into account the following:

- lubricate the cylinder with sealant;

- put on a new sealing ring;

- Establish the cylinder together with the bearing of deenergizing of coupling;

- insert the screws and tighten with a torque of 10 Nm;

- tighten pipeline 2 to 15 Nm;

- screw in the air outlet valve with a torque of 15 Nm;

- Establish a transmission;

- connect wiring (see fig. 152). Pay attention to the fact that the spring clip is fixed;

- Remove air from the clutch hydraulic actuator.

Visitor comments