Good work results can only be achieved with complete and appropriate tools. Therefore, before starting work, check your equipment: a bad tool that capitulates already before the first rusty screw or immediately begins to bend will create corresponding problems for you and ruin your mood. When purchasing tools, pay attention to their quality - a good tool has its price and is rarely available as a special offer on the shelves with goods in construction markets and trading houses. In addition, everything can be found in specialized stores. If you are going to actually put your own hands on this matter, then it is enough to always have the following basic equipment:

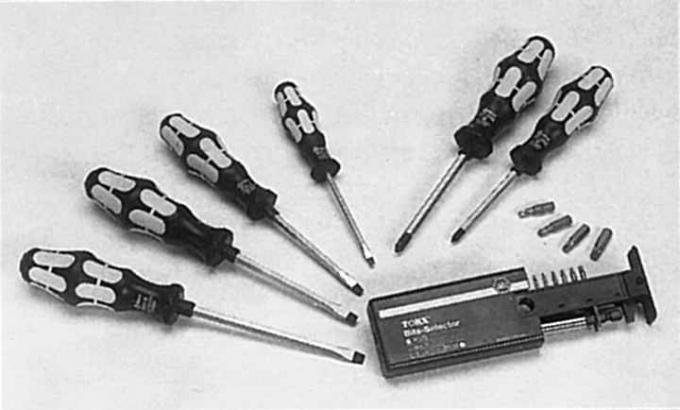

Screwdriver set with fixed, anti-slip handles for slotted, cross-head and torx screws. |

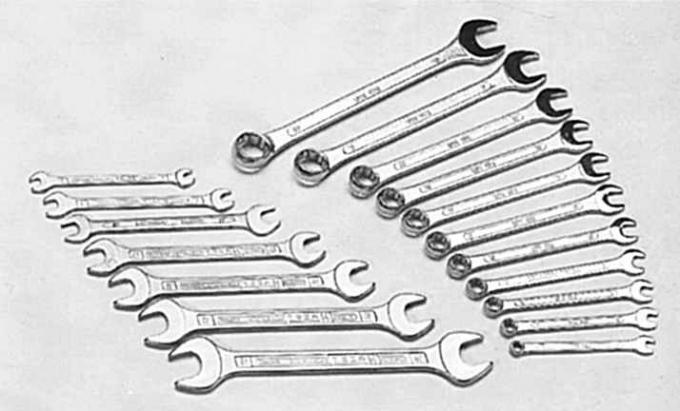

Sets of open-end and cap wrenches. It is desirable to have double fork wrenches with a jaw width of six to 19 millimeters. 10, 13, 17 and 19 mm ring/fork wrenches must be purchased for inverted double screw connections. |

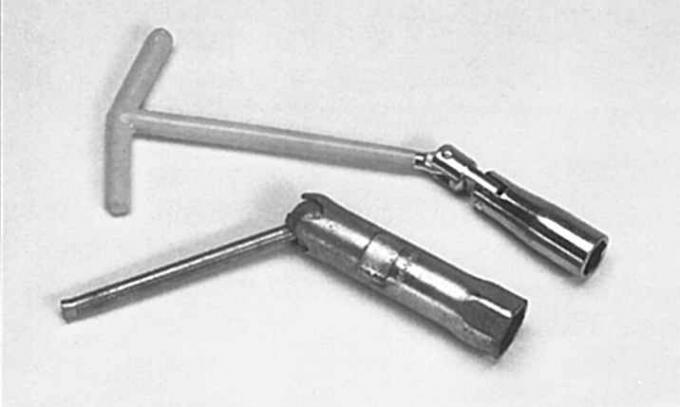

Key for spark plugs. Special insert wrench with rubber insert. |

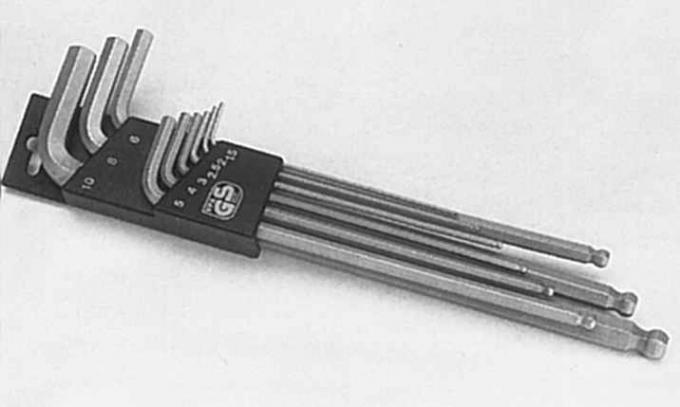

Allen keys (wrench for hexagon socket screws) in a set with sizes from 2 to 8 millimeters. |

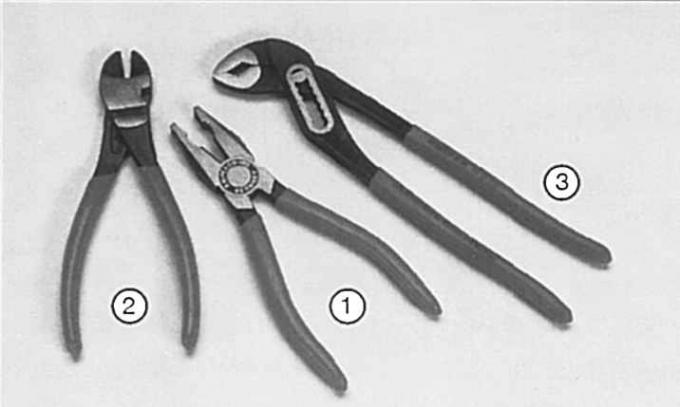

Pliers 1, side cutter 2 and water pump tongs 3 (length at least 240 mm). Thanks to them, you will be able to bend, fix, rotate and separate almost all materials in your car. |

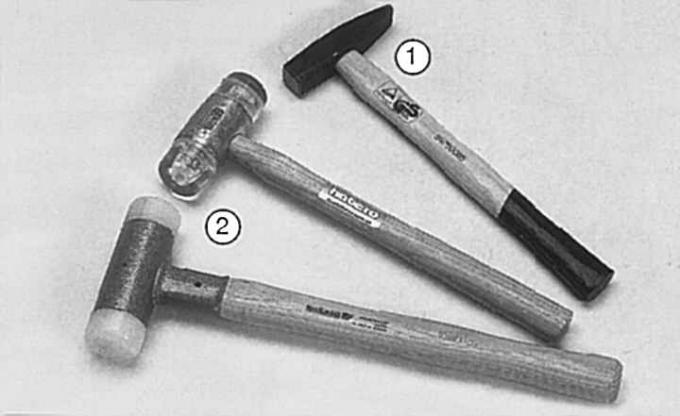

Locksmith's hammer 1 (recommended weight about 300g). Together with a punch, for example, it will allow you to release firmly seated bolts. Sensitive parts such as bearings, cast or hardened parts are best handled with a plastic or rubber mallet 2. |

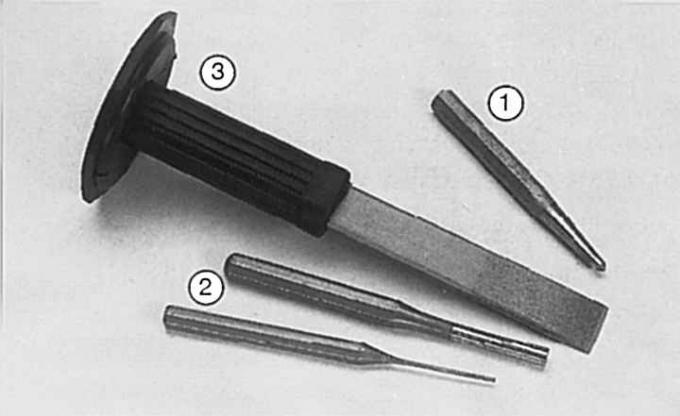

With the help of core 1, holes for drilling are filled. Punches 2 (diameter 3 and 6 mm) universally used in the dismantling and assembly of the running gear, engine and brake system. With flat chisel 3 (hardened blade) if necessary, deformed or heavily rusted screw connections can be dealt with. |

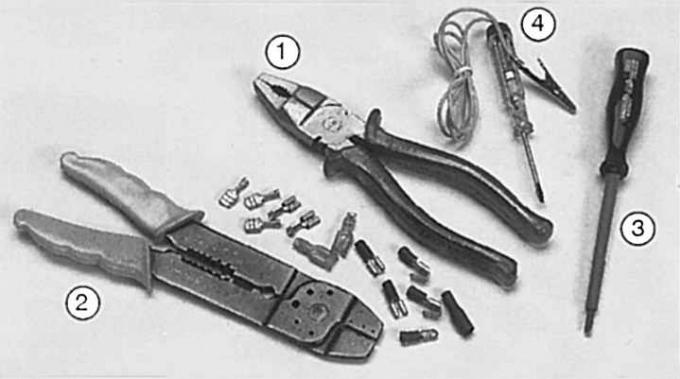

Work on cable harnesses or electrics requires, as standard equipment, insulating screwdrivers for slotted and cross-head screws 3 (sizes 1, 2, 3), phase control lamp 4, as well as insulating pliers 1 and crushing clamps 2. |

Work in the engine compartment, under the vehicle, on the undercarriage and on most ancillary units is most often carried out using the changeover torque wrench 2 (1/2" drive mechanism) and the corresponding set of keys. As a rule, a box with a set of such keys is 1. (Nozzles 10–32 mm, swivel, long/short extension, crank) Better to buy as a separate set. To perform work in the cabin, it is also desirable to have «box with a set of torque wrenches». In this case, it is sufficient to have, of course, a small ¼-inch drive. In addition to slotted, cross-slotted, torx screws and plastic clips, the manufacturer mainly uses screws with a width (SW) from 6 to 13 millimeters. |

| PRACTICAL ADVICE | ||

|

Visitor comments