Mobilizing the 200 Mondeos in unison are two four-cylinder engines in three different power options, a six-cylinder V6 (60°), as well as two diesel four-cylinder representatives with an exhaust gas turbocharger and a direct fuel injection system. Compact units are installed in the Ford Mondeo across the direction of travel. With regard to fuel consumption, smooth running, elasticity and power delivery, these engines are without limitation among the leading representatives of their generation, and in terms of exhaust gas parameters, experts have issued certificates for compliance with Euro 4 standards for carbureted engines and Euro 3 standards for diesel units.

Mondeo drive units

| Mondeo - from model year 2000 | Working volume (see3) | Power (kW/hp/min-1) | Power (Nm/min-1) |

| 1.8L 16V Duratec-HE |

1 798 |

81/110/5.500 |

165/3 950 |

| 1.8L 16V Duratec-HE |

1 798 |

92/125/6.000 |

170/4 500 |

| 2.0L 16V Duratec-HE |

1 998 |

107/145/6.000 |

190/4 500 |

| 2.5L V6 24V Duratec |

2 495 |

125/170/6.000 |

220/4 250 |

| 2.5L V6 24V Duratec (ST2200) |

2 495 |

151/205/6.500 |

235/5 500 |

| 2.0-L 16V DuraTorg-DI |

1 998 |

66/90/4.000 |

245/1 190 |

| 2.0-L 16V DuraTorg-DI |

1 998 |

85/115/4.000 |

280/1 900 |

All Ford Mondeo drive units are controlled by a Visteon Levanta processor with a CAN data bus. The 32-bit microcomputer bus is assisted in carbureted engines by a 3-D parameter for the ignition system, including the knock sensor. The cylinders are supplied with 95 Euro Super octane fuel, electronic sequential fuel injection system (SEFI).

Depending on the motorization, two different single-plunger distribution pumps for the injection system (Bosch VP 30, 66 kW/90 hp – Bosch VP 44, 85 kW/115 hp)

Provide «oil» diesel plants. Both pumps spray mixture «in two stages» through a twin-spring nozzle with a multi-jet atomizer directly into the combustion chambers: as soon as the first diesel ration (pilot injection) in the cylinders «on fire», the main injection is carried out in order to «soft» ignite it in the flame front of the first injection. In carbureted engines, the exhaust gas recirculation system (EGR) in conjunction with a three-way catalyst, it removes the exhaust gas; in diesel engines, this work is performed by an acid catalyst that assists the exhaust gas recirculation system.

Undeniably compact DONC (double-over-head-camshaft) Duratec engines made of light alloys with two massive flywheels can be attributed to Ford's technical innovations in engine building. One of the clearly defined goals of these developments was to increase the value of torque and power, as well as to simplify the performance of service work: for example, during inspections and maintenance.

Therefore, in four-cylinder engines, all components involved in the preparation of a combustible mixture are located in front, in V6 they can be found in the middle between the cylinder blocks. And the rest, carried out on the occasion of the check, are performed quickly on the basis of manual elementary routine actions and do not require «surgeon's hands».

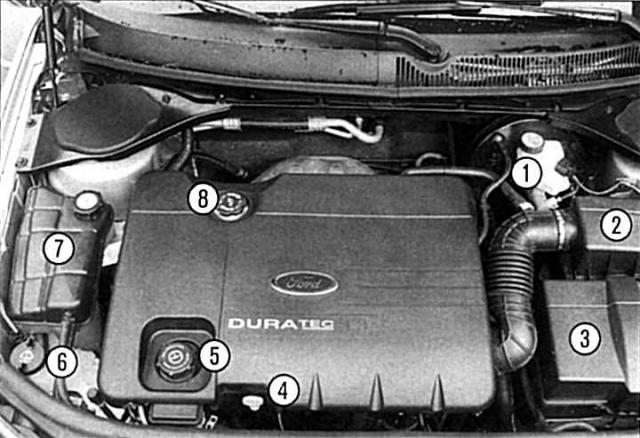

Engine compartment Duratec-HE 16V: 1 - Compensation tank with fluid for brakes and clutch,

|

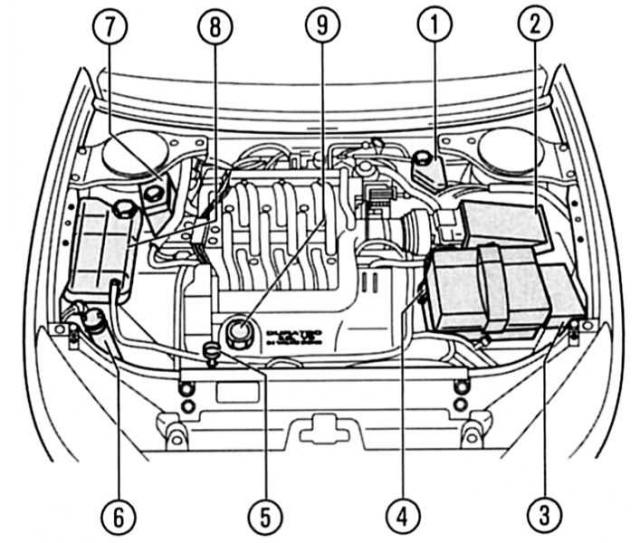

Engine compartment Duratec-HE 24V: 1 - Compensation tank with fluid for brakes and clutch,

|

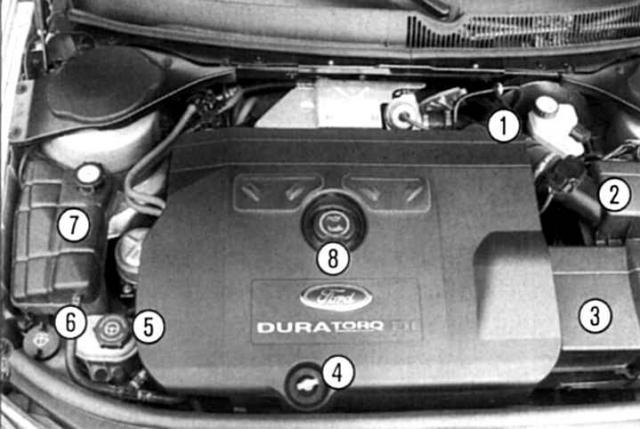

Engine compartment DuraTorg-DI 16V: 1 - Compensation tank with fluid for brakes and clutch,

|

Technical cooperation with Mazda

The basic idea for Duatec engines came about as a result of cooperation with the company Mazda, a subsidiary of Ford on the Far East horizon. However, this is not the first contact with the Far East, which Ford has turned into useful results: in cooperation with Yamaha, the world-famous four-cylinder Zetec engines appeared. They celebrated their debut in the Fiesta, and in the Zetec-SE version with 1.4 / 1.6-liter displacement, they also appeared in the Focus.

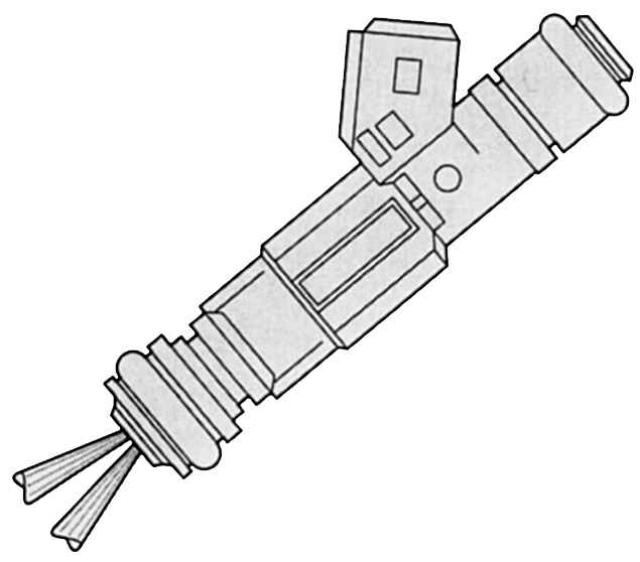

A certain injection angle: the fuel reaches the same parts in front of the intake valves. |

The technical features of Duratec units include controlled nozzles. Their four nozzle holes are installed strictly at a certain angle in the combustion chamber. two holes «directed» on the left and two others on the right inlet valve. The fuel is converted into a particularly homogeneous gas, thanks to which it «burns down» more effective.

Due to the precise control of the air-fuel mixture, engineers have realized a balanced cylinder filling level, a stable combustion process, «stable» idling and for all load conditions the most suitable exhaust emissions compared to older Endura engines.

The engine block and cylinder head, as well as the housings of most auxiliary units in the new generation of Duratec engines, are made of a special aluminum alloy. To further reduce weight, the valve covers were made from magnesium and the intake pipes from plastic.

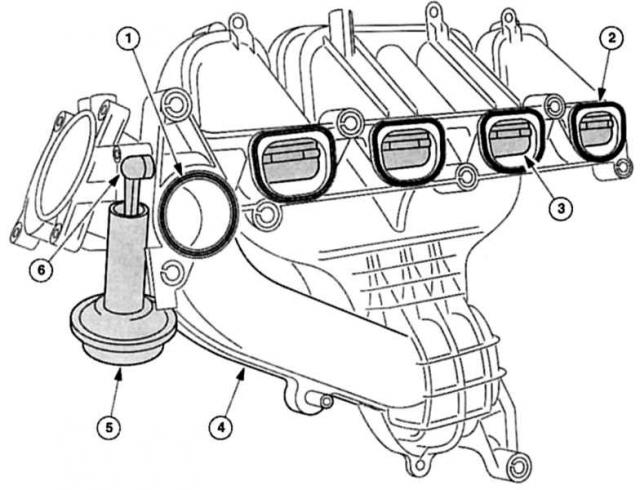

Synchronous control: butterfly valves (swirl flaps) activates a common shaft in the intake manifold. 1 - Laying the exhaust gas recirculation system,

|

Two camshafts located on top rotate in the cylinder heads, they control the operation of the four valves of each combustion chamber respectively. A number of design measures support elegant and almost noise- and vibration-free operation, low exhaust gas emissions, as well as favorable low maintenance costs. Thanks to the use of wear-resistant materials, Duratec motors make do with simple bucket tappets. The valve clearance on four-cylinder engines is checked as a last resort after repair work has been carried out on the valve actuator or after approximately 150,000 kilometers. To adjust the gap, the pushers are measured and completely replaced. In the V6 and both diesels, the valve clearance is adjusted using hydraulic tappets. Mondeo with carbureted engine should be checked every 60,000 kilometers, diesel should «stretch out» before checking 15,000 kilometers less.

In petrol engines, according to Ford, besides «deadline is coming» spark plugs, engine oil and oil filter perform their duties for 20,000 kilometers. The diesel driver is required to change the engine oil, according to the program, after every 15,000 kilometers.

Duratec-HE – RPM-optimised, flexible and cost-efficient

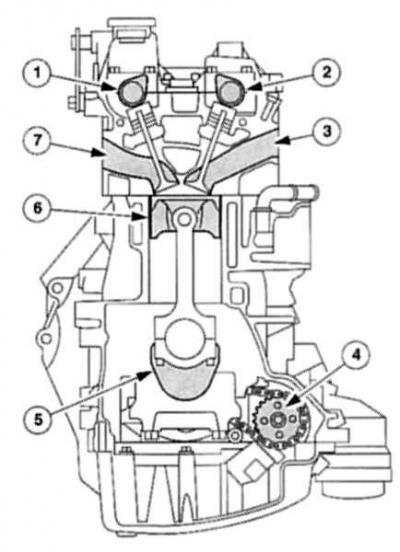

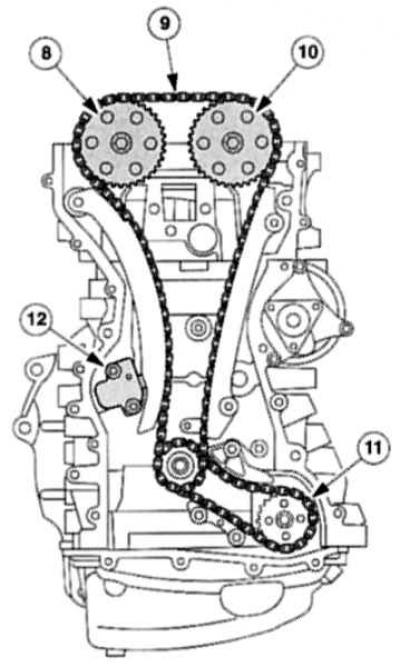

«Deftly» running and quiet: control of Duratec-HE-motors.

|

|

1 - exhaust camshaft,

2 - intake camshaft, 3 - inlet channel, 4 - drive chain wheel of the oil pump, 5 - crankshaft, 6 - piston, 7 - outlet channel, 8 - drive wheel of the exhaust camshaft, 9 - drive chain of pin links, 10 - drive wheel of the intake camshaft, 11 oil pump drive chain, 12 hydraulic chain tensioner. |

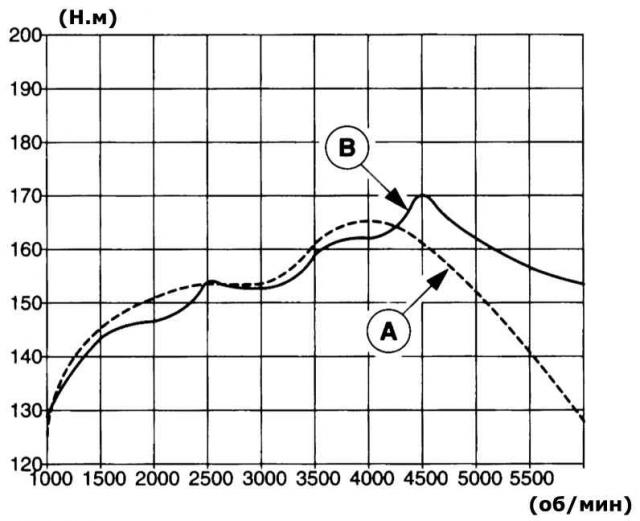

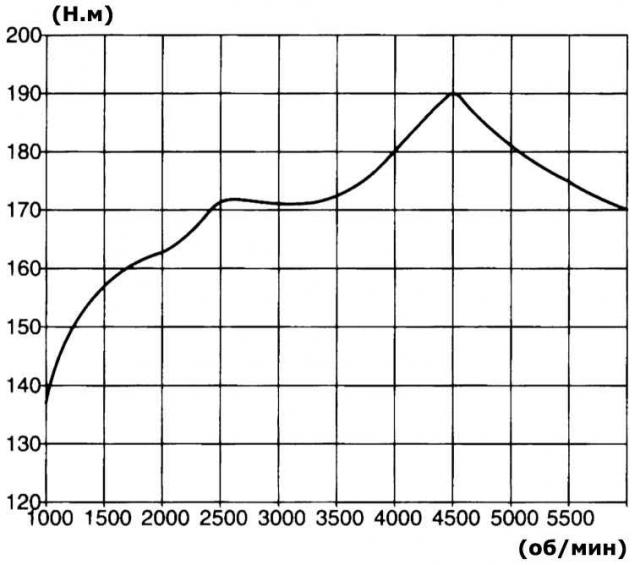

A - Torque curve of a 1.8-liter engine with 81 kW / 110 hp. B - Torque curve of a 1.8-liter engine with 92 kW / 125 hp. |

The torque curve of the 2.0-litre engine with 107 kW/145 hp |

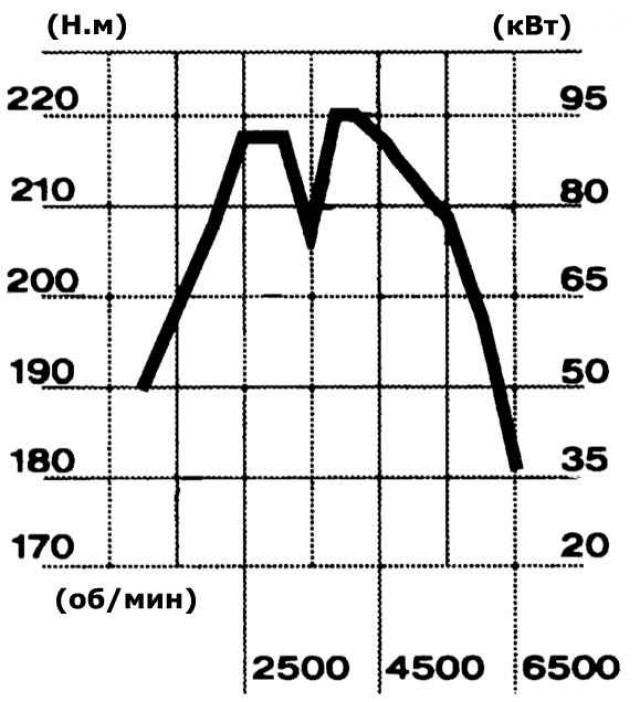

The torque curve of the 2.5-litre V6 engine with 125 kW/170 hp |

Both basic versions are equally mobile and flexible DONC drive units. The 1.8-liter differs from the 2.0-liter only in a different ratio of piston stroke to cylinder diameter, a camshaft with modified valve timing and larger valves. In terms of constantly optimizing friction and good rotational culture, both engines feature highly-drilled gray cast iron cylinder liners cast into an aluminum engine block with light alloy pistons and coated with a special coating, including friction-reduced piston rings.

Quiet and «deftly» the running chain of a drive from pin links reduces noise and vibrations of the engine besides. The chain is maintenance free and under normal operating conditions will keep the engine running for a long time. This also applies to the oil pump drive chain, together with the sprocket, it is in contact with the end of the crankshaft: the water pump and servo pump, alternator and AC blower, on the contrary, are driven by drive belts.

Two camshafts rotate in the cylinder heads of Duratec-HE engines. They control, in each cylinder, respectively, two intake and exhaust valves located at an angle of 42°to each other. The drive drives a maintenance-free chain with a hydraulic tensioner. The chain is fixed on both sides of the engine by wear-resistant and maintenance-free plastic guide bars - these «reiki» have a significant effect on the mechanical vibration damping of engine controls.

All constructive measures are aimed not only at audibility and sensitivity, but also, which is important for the Mondeo owner, at the fuel dispenser: with an average consumption of 7.7 l / 100 km (7.8 l/100 km) «small» Duratec-HE burns their super-gasoline Mondeo sedan quite moderately. They reach their maximum speed of 193 km/h (205 km/h) and perform acceleration from 0 to 100 km in 11.6 seconds (10.8 seconds). With a working volume of 2.0 liters, such a Mondeo already requires 8.0 l / 100 km, «rushes» with a top speed of 215 km/h and accelerates from 0 to 100 km in 9.8 seconds.

Duratec-VE V6 24V - small differences in details with big consequences

Duratec-VE V6 24V installed already between the front wheels «old» Ford Mondeo, which did not lead to a bad figure of the car. However, engine builders set to work on it, and for use in the Mondeo II they successfully rejuvenated and modified it. strong «heart Mondeo» mobilizes from the 2.5-liter displacement, as before, 125 kW/170 hp. at 6000 rpm. (ST220: 162 kW/220 hp at 6,000 rpm) - but much lighter: the main modification took place in the cylinder heads. Here, the valve timing in all operating states has been optimized. Result: Duratec-HE «soft» hangs on the accelerator pedal and releases its exhaust gases into the atmosphere much cleaner than before. Ford's V6 complies with Euro 5 regulations coming in 2005.

Beneath the surface, not only is this decisive factor of progress to be found, there are also many small modifications that make up the differences. For example, modified intake ports for increased swirl, new high voltage output electronic ignition coil, Duratec-HE matched fuel system, modified exhaust gas pressure differential valve (DPFE), knock sensor application (KS), compact camshaft drive, optimized intake changeover drive (IMRC), a redesigned accessory belt drive, and not the worst of Visteon Levanta's new 32-bit engine control system, which uses for «communications» CAN bus.

Tested in Mondeo – technology

Formula 1 large edition

The Duratec-VE V6 is one of the lightest and most compact V6 engines available. Its cylinder head and engine block appeared, for example, after the advent of special methods developed by the English motor builders of Cosworth, casting from extremely light aluminum alloys. And by the way: the Mondeo V6, with a 60°camber angle, was after its introduction so far the first large-scale engine to be manufactured using this technology - originally it was the privilege of only Formula 1 engines.

Tricks within the engine make the Duratec-V6 an equally fast and powerful drive unit that comes into play with the Mondeo in all situations. The maximum torque of 220 Nm Duratec reaches at 4250 rpm, but already at over 1500 rpm it «pulls» on front wheels up to 6250 rpm constantly at least 87% (190 Nm). The V6 in the Mondeo model with a body characterized by a pronounced angle between the rear window and the trunk, runs from 0 to 100 km / h in 8.7 seconds and quickly reaches its maximum speed of 225 km / h. And this is with moderate thirst: on average, he lightens his 58-liter tank every 100 km by 9.8 liters of super gasoline.

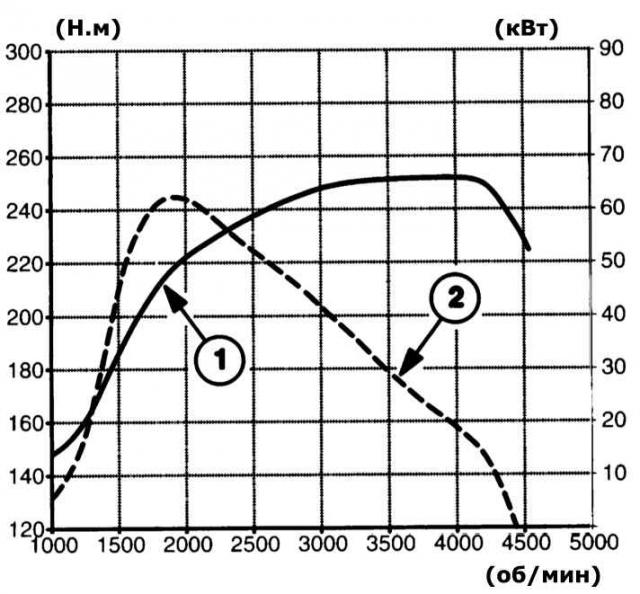

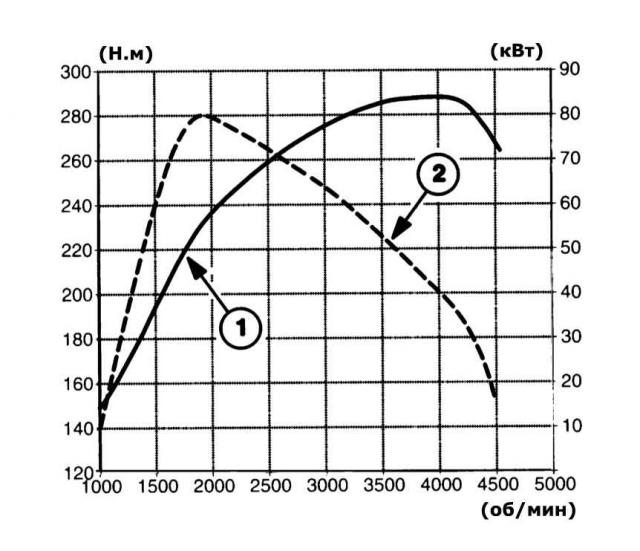

Double pack turbodiesel - direct injection with 66 kW/90 hp and 85 kW/115 hp

The DureTorg DI engine is based on the 2.0-litre DuraTorg turbodiesel used in light duty vehicles. For use in the 2000 Mondeo, this four-cylinder engine in two outputs has been radically upgraded. This duo offers design features that elevate the power output of today's direct injection turbodiesels almost to the level of theirs «colleagues with spark plugs». Among other things, these include a turbocharger integrated in the exhaust manifold - in the 85 kW version with variable turbine geometry - a light alloy cylinder head with two overhead camshafts and 16 valves, a hydraulic valve lifter, a high-pressure fuel pump drive and a camshaft with a double circuit and with a hydraulic tensioner, as well as a charge air cooler that lowers the intake charge temperature by up to 100°C. Extra extended cranks (160 millimeters) actuate rounded balancers with rotating masses on a crank mechanism. And so that gas exchange also occurs «full», both DureTorg DIs operate with a single plunger distribution injection pump (66 kW - Bosch VP 30, 85 kW - Bosch VP 44), which dose diesel fuel in the combustion chambers in two stages.

DureTorg DI prove their worth «internal» perfection on the road with optimum fuel consumption, time-honored emissions and attractive ride. The engine with 66 kW at 1900 rpm delivers its best torque of 245 Nm on dual-mass flywheels. The sedan model performs acceleration from 0 to 100 km / h in 13.1 seconds and at 180 km / h «acceleration» stops. It goes without saying that the 85 kW Mondeo pulls its front wheels even harder: for example, at 1900 rpm with 280 Nm, it sprints from 0 to 100 km/h «only» in 9.8 seconds or an hour for a maximum of 195 kilometers. If nevertheless «normal» temperament is not reached, then the engine control of a 115-horsepower diesel engine briefly gives «green light» on «excess profit» – in the area of full load, the torque increases to 310 Nm.

With all its temperament and comfort of driving near the gas station, the Mondeo remains with its diesel heart and limits itself to some extent. Whether it's 90 or 115 horsepower: on average, a maximum of 5.9 liters disappear from the tank every 100 kilometers - by European standards, it's pretty decent to meet exhaust gas regulations in accordance with Euro 3.

Power Curve 1 and Torque Curve 2 DureTorg DI 66 kW/90 hp |

Power Curve 1 and Torque Curve 2 DureTorg DI 85 kW/115 hp |

Visitor comments