|

PROCEDURE |

- Raise the vehicle, level it and secure it so that it does not wobble.

- If the rusted screw connections cannot be released, try to twist the nuts - most often the screws can then be torn off. Use only new screws, spring rings, nuts and gaskets for installation.

- For safety reasons, also replace all mounting rubber.

- If the exhaust system has already undergone partial repairs, then disconnect the pipe ends best of all in a heated state. In workshops, a welding torch is used for this - as a rule, a good tool for homework. Be sure to protect your hands and eyes with work gloves and goggles. Also, keep a fire extinguisher nearby.

- Practical advice: before turning on the burner, first try your luck with rust-dissolving agents.

- Separate the pipes and flanges further with strong rotational movements, support them with light hammer blows.

- If this does not help, stub or cut the joint about 10 centimeters from the joint. Further saw off the rest of the pipe to the point of separation in the longitudinal direction and lift it with a strong screwdriver.

- Subsequently, the screw connections of the exhaust system will be easier to release if the threads are lubricated with heat-resistant copper grease before installation. This remark can be applied to overlapping pipe connections.

|

|

Don't Trust Small Hanging Loops - Keep an Eye Out When Checking Your Exhaust System

On the engine side, the exhaust system is firmly screwed to the exhaust manifold. Under the bottom of the car, it is freely suspended using rubber loops. If your exhaust system starts «buzz and ring» or even touch the ground, no longer trust welds, mufflers and hanging loops. Check «rusty» places, and do not be afraid to use hammer blows for this.

|

PROCEDURE |

- Check the rubber loops for breaks, cracks or other damage and replace if necessary. To test, shake the outlet tube vigorously back and forth.

- Check all connections on the manifold flanges for firm seating.

- Start the engine and insert a rag into the end tube. After a while, the engine should stop. If you hear hissing sounds or the engine continues to run, the system is leaking.

- Strong combustion noises and popping noises during over idle are unmistakable indications of defects in the exhaust system.

- Tap lightly with a hammer on the entire surface of the mufflers and pipes. Do not forget the front walls of the mufflers - at the same time, strike not so timidly. If the metal sheet «healthy», your beats sound «dry and clear», rotten metal you will recognize by muffled sounds.

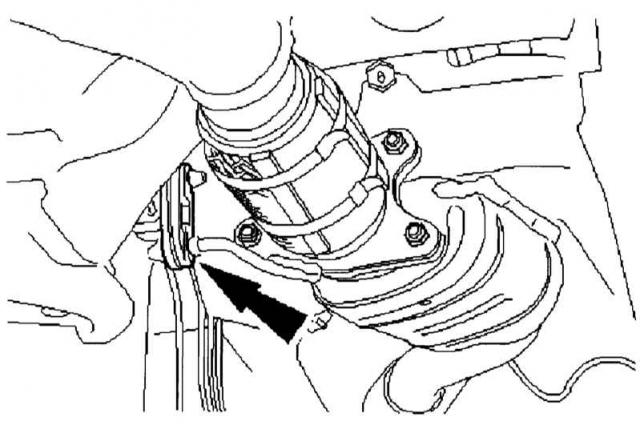

Better to replace completely: Rubber loops (indicated by an arrow) after work has been done on the exhaust system. |

|

|

Visitor comments