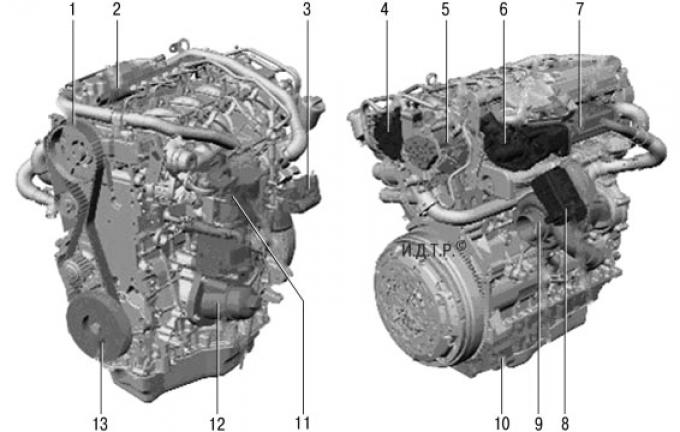

Pic. 5.48. Duratorq-TDCi engine with a volume of 2.2 liters: 1 - timing belt; 2 - distribution manifold of the fuel injection system; 3 - electronically controlled inlet pipe damper; 4 – vacuum pump; 5 - fuel pump; 6 - exhaust gas recirculation system (EGR) with electric control; 7 - radiator of the EGR system; 8 - electric actuator for adjusting the guide vanes of the turbocharger; 9 - turbocharger with adjustable nozzle apparatus; 10 - oil sump extension; 11 - fuel filter; 12 - block oil filter / oil cooler; 13 - crankshaft damper.

2.2L Duratorq-TDCi engine (pic. 5.48) – four-cylinder, in-line, turbocharged diesel engine, two camshafts, 16 valves, a balancer shaft block for optimal running smoothness, an exhaust gas recirculation system (EGR).

The cylinder block is made of cast iron, with cast cylinder liners and double walled for high strength. In addition, an air jacket has been additionally created, which significantly improves sound insulation. Cylinder mirrors are bored directly in the cylinder block. To fix the head gasket in the cylinder block, two holes for guide bushings are made.

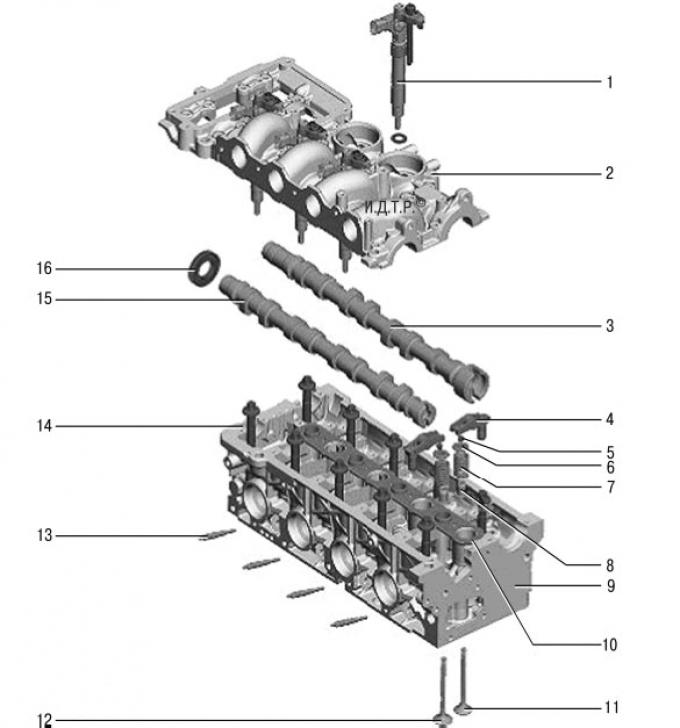

Pic. 5.49. The cylinder head of the Duratorq-TDCi engine with a volume of 2.2 liters: 1 - fuel injector; 2 – the top part of a head of the block of cylinders; 3 – a camshaft of final valves; 4 - roller pusher; 5 – cracker of a valve spring; 6 - the upper plate of the valve spring; 7 - valve springs; 8 - the lower plate of the valve spring; 9 - the lower part of the cylinder head; 10 - gasket; 11 - exhaust valves; 12 - inlet valves; 13 - glow plug; 14 – bolts of fastening of a head of the block of cylinders (10 pieces.); 15 - intake camshaft; 16 - an epiploon of a final camshaft.

cylinder head (pic. 5.49) composite, aluminum, consists of two parts. The lower part of the cylinder head is attached to the cylinder block with ten bolts. Reuse of bolts is not allowed, as they have a programmed deformation when tightened.

The laminated steel cylinder head gasket is available in four thicknesses depending on the piston protrusion.

NOTE: The upper and lower parts of the cylinder head are matched to each other according to their tolerances. They cannot be replaced individually.

Cylinder head cover with integrated crankcase ventilation valve. The seal between the head cover and the top of the block head is made in the form of a flat gasket.

The camshafts are made of cast iron. The intake camshaft rear end drives the vacuum pump, the exhaust camshaft rear end drives the fuel pump. The seal is a rubber O-ring.

The exhaust camshaft is driven by a toothed belt from the crankshaft, the intake shaft is driven by a chain from the exhaust camshaft. The chain tension is carried out by a hydraulic tensioner.

The upper parts of the camshaft bearings are made in the upper part of the cylinder head. The camshafts rotate directly in aluminum bearings.

A hole is made in the upper cover of the gas distribution mechanism housing for installing a special tool for fixing the gear pulley of the exhaust camshaft when checking the correct installation of the gas distribution phases.

The hydraulic timing chain tensioner is attached to the top of the cylinder head between the camshaft sprockets.

The oil pressure to the hydraulic drive chain tensioner is transmitted through a channel in the cylinder head. The compression spring in the hydraulic timing chain tensioner provides the required chain preload.

NOTE: A locking pin is provided on the chain tensioner to loosen the chain pre-tension during maintenance work.

NOTE: After installing the top of the cylinder head, make sure the hydraulic chain tensioner is in the loose position.

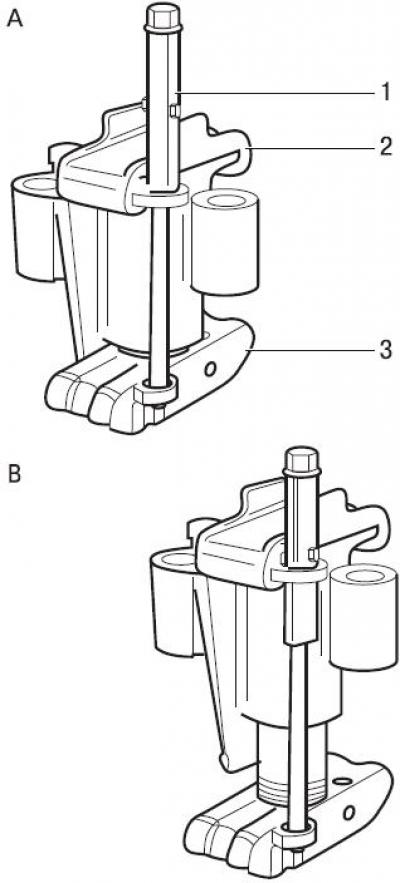

Pic. 5.50. Fixing and loosening the hydraulic timing chain tensioner: A - the chain tensioner is fixed; B - the chain tensioner is loose; 1 - locking pin; 2 – the top directing of a chain; 3 - lower chain guide.

To fix the hydraulic chain tensioner, lift the pin 1 (pic. 5.50) and then rotate it 90°.

To pre-tension the hydraulic chain tensioner, turn the service pin 90°again.

The crankshaft has five main bearings. Each main bearing cap is stamped with the corresponding cylinder number for identification.

The axial movement of the crankshaft is limited by four semi-circular thrust washers, which are located on both sides of the middle main bearing. The thrust washers have oil grooves that must face the main bearing.

Each main bearing housing and cap is provided with an upper and lower bearing shell. The upper bushings have a hole and an annular groove for supplying oil under pressure from the main bearing through the crankshaft holes to the connecting rod bearings.

To create optimum crankshaft main bearing clearance, there are five thicknesses of the lower main bearing shells.

On the third neck of the crankshaft, the balancer shaft drive gear is pressed in a hot state.

The connecting rods are made from forged steel.

The upper head of the connecting rod tapers on both sides, forming a cone. The conical shape improves the distribution of forces between the piston and connecting rod during the combustion stroke. A bronze bushing is installed in the upper head of the connecting rod, in which an internal groove is made for supplying oil to the piston pin. The lower head of the connecting rod is composite. The cover is attached to the connecting rod with two bolts.

The piston is made of aluminum alloy and has three piston rings. A steel insert is installed in the groove of the upper piston ring of the piston for reinforcement.

NOTE: Piston rings must be installed so that the locks are at an angle of 120° (with a tolerance of 15–20°) one from the other around the circumference of the piston.

The top two compression rings are embossed with "Top" for ease of installation.

The working surface of the piston is graphitized to reduce friction on the cylinder mirror.

To cool the pistons, piston cooling nozzles are installed in the lower part of the cylinder liners. These nozzles spray the engine oil evenly under the piston crown. Oil channels are located in the bottom of the piston. Atomized oil enters these oil passages, providing the required piston cooling.

The balance shafts of the shaft balancing unit counteract the forces of inertia (due to the oncoming movement of piston pairs) on the crankshaft.

NOTE: The balance shaft assembly should not be removed for maintenance.

The balancer shaft block is located under the crankshaft. The block assembly is attached with eight bolts to the bottom of the cylinder block. The oil pump is located on the underside of the balance shaft housing. Using shims, set the required clearance in the gearing between the driven gear of the balance shaft and the drive gear on the crankshaft.

The balance shaft drive gear on the crankshaft rotates the drive balance shaft in the opposite direction of the crankshaft rotation. The driven balance shaft rotates from the drive balance shaft in the same direction as the crankshaft. The number of teeth on the balance shaft drive gear on the crankshaft is twice that of the mating gears on both balance shafts. Therefore, the gear ratio is 1:2.

The rotary type oil pump is fixed to the balance shaft block with four bolts. With another bolt located in the oil strainer, the oil pump is attached to the guide tube of the engine oil level indicator.

The pump is driven from the crankshaft by a chain.

The oil pump develops a maximum allowable oil pressure of approx. 6.5 bar and a maximum flow of 50 l/min.

The safety valve in the oil pump outlet port protects the oil pump and lubrication system components from excessive pressure in the system. The pressure relief valve opens at 8 bar. Excess oil flows back into the oil sump.

The oil filter/oil cooler unit is located under the intake pipe at the level of the third cylinder. A replaceable paper filter element is installed in the filter housing. The oil cooler from the cylinder block is supplied with liquid from the cooling system. Coolant flows from the radiator to the thermostat.

The intake pipe is designed in such a way that the forced air is evenly distributed over all eight of its intake channels.

In addition, crankcase gases from the crankcase ventilation system and exhaust gases from the EGR system are supplied to the intake pipe (exhaust gas recirculation).

The sealing of the intake channels in the cylinder head is ensured: - for the four lower swirl channels, - by means of an O-ring; – for the top four channels that create maximum filling – with a rubber gasket.

The intake pipe is attached to the cylinder head with seven bolts.

The exhaust manifold is secured to the cylinder head with nine self-locking nuts.

Additionally, a spacer sleeve is installed on each exhaust manifold mounting stud. The spacers compensate for the change in clearance between the exhaust manifold and the cylinder head as the exhaust manifold heats up or cools down.

A connecting flange is made on the exhaust manifold for installing a turbocharger and an exhaust gas recirculation valve (EGR).

A thermal screen is mounted above the exhaust manifold. It protects heat sensitive parts in the exhaust manifold area.

In addition, the thermal shield prevents skin burns in case of accidental contact with a hot exhaust manifold.

The geometry of the guide vanes of the turbocharger is changed by means of an electric actuator.

The turbocharger shaft is lubricated and cooled by engine oil through the inlet pipe.

During operation, the speed of the turbocharger shaft can reach 200,000 min-1.

Through the EGR system (exhaust gas recirculation) part of the exhaust gases is again directed to the flow of fresh air entering the engine cylinders. The proportion of returned exhaust gases is highly dependent on engine speed and engine load. Exhaust gas recovery is particularly effective in the lower part load range. Under favorable conditions, the share of return can exceed 60%. The EGR valve consists of a DC motor and a position sensor.

The radiator of the exhaust gas recirculation system is included in the engine cooling circuit (EGR). By cooling the EGR system, nitrogen oxide emissions are reduced.

Visitor comments