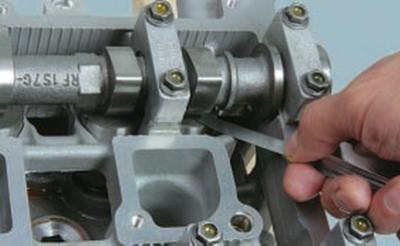

The gap is measured with a feeler gauge on a cold engine (at +20°C) between the camshaft cam (the cam must be pointing up from the pusher) and valve lifter. The nominal clearance for the intake valve is 0.17-0.23 mm, for the exhaust valve - 0.31-0.37 mm.

The gaps are adjusted by selecting the thickness of the pushers. Spare parts are supplied with sets of pushers of different thicknesses.

Regarding the timing gear drive, the valves located on the right are exhaust, on the left are inlet.

The work on adjusting the clearances in the valve drive of all engines is the same.

You will need: all the tools needed to remove the camshafts, as well as a set of flat feeler gauges.

1. Set the piston of the 1st cylinder to the TDC position of the compression stroke (see Setting the No. 1 Cylinder Piston to TDC on the Compression Stroke).

2. Remove all spark plugs.

3. Remove the cylinder head cover (refer to Cylinder Head Cover Gasket Replacement).

4. Measure the gaps between the cams of both camshafts and the valve lifters of the 1st cylinder with a feeler gauge. Record the measured clearances.

5. Turning the crankshaft by the bolt of its pulley each time by 180°, measure and record the clearances at the valves of the remaining cylinders. The order of operation of the cylinders: 1–3–4–2. It is necessary to replace the tappets of those valves, the gaps in the drive of which differ from the nominal values. After measuring all the gaps, set the piston of the 1st cylinder to the TDC position of the compression stroke.

6. Remove camshafts (see Replacing camshafts).

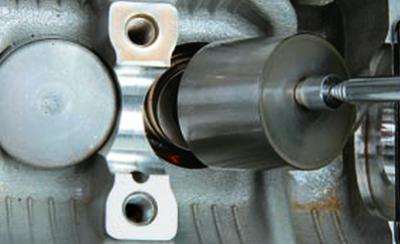

7. Remove the valve lifter that requires clearance adjustment from the cylinder head socket and record its thickness (it is indicated on the inner surface of the pusher).

NOTE: The number stamped on the inside surface of the valve lifter is the tappet thickness. However, only three digits after the decimal point are shown (for example, the number "650" means the thickness of the pusher is 3.650 mm).

8. Calculate the thickness of the new pusher using the formula (all values in mm) H \u003d B + A - C, where A is the value of the measured gap; B is the thickness of the old pusher; C - nominal clearance; H is the thickness of the new pusher.

9. Install the new pusher in place.

10. Similarly, replace the tappets of all valves that require clearance adjustment.

11. Install the camshafts, but do not install the timing gear yet.

WARNING: Rotate the crankshaft 90°counterclockwise so that all pistons are centered.

12. Turning the camshafts for the hexagons made on them, measure the resulting gaps with feelers. If the gaps are out of specification, repeat the adjustment (see paragraphs. 6–8).

13. If all backlashes correspond to nominal values, establish a drive of the gas-distributing mechanism and all removed details in an order, the return to removal.

Visitor comments