NOTE: Work on a manhole, overpass or, if possible, on a lift.

1. Remove the accessory drive belt.

2. Pinch the expansion tank hoses with a special tool to avoid coolant leakage, and disconnect the hoses from the tank by removing the hose clamps.

3. Securely support the engine.

4. Remove the right suspension bracket of the power unit (refer to Right Powertrain Mount Replacement).

5. Remove the front timing cover.

6. Place the transmission lever in neutral position.

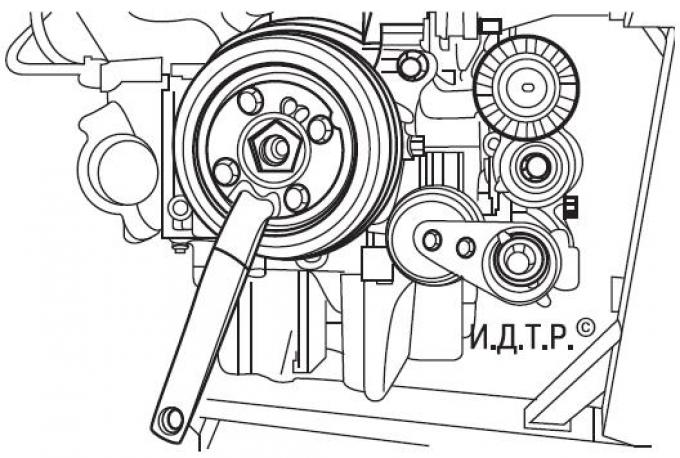

7. Install a special key on the timing belt pulley on the crankshaft (pic. 5.43), by fixing it with four bolts.

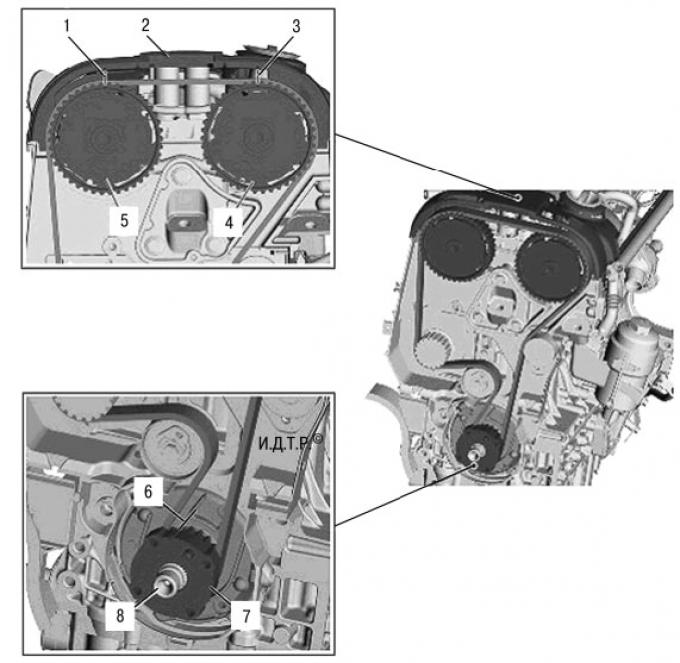

8. Turn the engine crankshaft so that the marks on the VCT mechanisms (valve timing changes) camshafts were installed in the same way as shown in fig. 5.41.

Pic. 5.41. Mounting marks (valve timing): 1 - alignment mark of the exhaust camshaft pulley; 2 - cover of the gas distribution mechanism drive with alignment marks; 3 - alignment mark of the intake camshaft pulley; 4 – a gear pulley of an inlet camshaft; 5 – a gear pulley of a final camshaft; 6 - alignment mark of the gear pulley of the timing gear drive on the crankshaft; 7 - toothed pulley of the timing belt on the crankshaft; 8 - crankshaft.

9. Fix the crankshaft from turning by turning on the IV gear in a manual gearbox (or set the automatic transmission selector to position "P" - parking), and apply the parking brake to the vehicle.

10. Loosen the tension of the timing belt, for which loosen the tensioner central bolt, insert the hexagon into the adjusting hole and turn the tensioner pulley counterclockwise.

11. Remove the belt from the VCT gear pulleys, crankshaft and idler pulley.

12. Put on a new belt.

NOTE: The timing belt should be installed starting from the crankshaft pulley, then to the intermediate pulley, the intake and exhaust camshaft pulleys, the water pump pulley, and finally to the timing belt tensioner pulley.

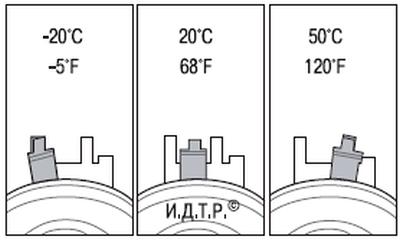

13. Set the position of the tension roller depending on the temperature of the engine (see fig. 5.42) and tighten the center bolt of the timing belt tensioner. The tension roller spring will set the required tension of the timing belt.

14. Shift the transmission into neutral and check that the belt is correctly installed. To do this, turn the crankshaft two turns clockwise and check the position of the alignment marks.

15. If the timing belt is installed correctly, install all removed parts in the reverse order of removal.

Pic. 5.42. The positions of the adjusting elements of the timing belt tensioner of the Duratec-V15 engine with a volume of 2.5 liters at different engine temperatures.

Pic. 5.43. Key for turning the crankshaft

Visitor comments